Abstract

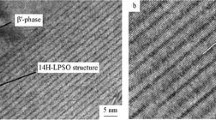

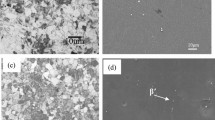

A high-strength Mg–9Gd–3Nd–1Zn–1Sn–0.5Zr (wt%) alloy bar was successfully fabricated by extrusion and following aging two-steps processes, during which the alloy′s microstructures were determined to investigate the refinement mechanism during extrusion and to reveal the morphology precipitation behavior of the as-extruded alloy after aging. Based on the characterization of the mechanical properties, the strengthening mechanism of the alloy under different treatment processes had been discussed. Our results showed that the greater the extent of extrusion, the finer the grains and eutectic phase, and crushing and dynamic recrystallization are the refinement mechanisms of the alloy in narrow-zone. After peak-aged treatment at 200 °C, a large number of spherical β′ phase and lamellar precipitated phase had been observed, which replaces the amorphous β" phase of the alloy was under-aged. The ultimate tensile strength, yield strength, and elongation were 462.12 MPa, 391.97 MPa, and 4.2% respectively, and the increase number of the β′ phase and long-period stacking ordered (LPSO) phase were the reason why the strength of the alloy reached the highest value. At the over-aging stage (96 h), the size of the lamellar precipitates and the LPSO was larger than that of the peak-aged, and the spherical β′ phase appeared in peak-aging stage decreased significantly, which reduced its performance.

Graphic Abstract

Similar content being viewed by others

References

L. Tonelli, L. Pezzato, P. Dolcet et al., Effects of graphite nano-particle additions on dry sliding behaviour of plasma-electrolytic-oxidation-treated EV31A magnesium alloy against steel in air. Wear 404–405, 122–132 (2018)

V.G. Tkachenko, K.H. Kim, B.G. Moon et al., Design and microstructural analysis of magnesium alloys for dynamical applications. J. Mater. Sci. 46(14), 4880–4895 (2011)

C. Blawert, N. Hort, K.U. Kainer et al., Automotive applications of magnesium and its alloys. Trans. Indian Inst. Met. 57(4), 397–408 (2004)

H.Y. Yang, X.W. Guo, G.H. Wu et al., Electrodeposition of chemically and mechanically protective Al-coatings on AZ91D Mg alloy. Corros. Sci. 53, 381–387 (2011)

A.J. Carpenter, A.R. Antoniswamy, J.T. Carter et al., A mechanism-dependent material model for the effects of grain growth and anisotropy on plastic deformation of magnesium alloy AZ31 sheet at 450 °C. Acta Mater. 68, 254–266 (2014)

X.Y. Xia, W.H. Sun, A. Luo et al., Precipitation evolution and hardening in MgSmZnZr alloys. Acta Mater. 111, 335–347 (2016)

Y. Hu, N. Yu, L.Z. Zhao et al., Effect of Sm on the microstructure and properties of Mg–9Al alloy. Int. J. Cast Met. Res. 30(6), 317–321 (2017)

H.R.J. Nodooshan, G.H. Wu, W.C. Liu et al., Effect of Gd content on high temperature mechanical properties of Mg–Gd–Y–Zr alloy. Mater. Sci. Eng. A 651, 840–847 (2016)

X.G. Sun, M. Nouri, Y. Wang et al., Corrosive wear resistance of Mg–Al–Zn alloys with alloyed yttrium. Wear 302(1–2), 1624–1632 (2013)

Z. Hu, R.L. Liu, S.K. Kairy et al., Effect of Sm additions on the microstructure and corrosion behavior of magnesium alloy AZ91. Corros. Sci. 149, 144–152 (2019)

W. Rong, Y. Zhang, Y.J. Wu et al., Fabrication of high-strength Mg–Gd–Zn–Zr alloys via differential-thermal extrusion. Mater. Charact. 131, 380–387 (2017)

X.J. Zhou, C.M. Liu, Y.H. Gao et al., Microstructure and mechanical properties of extruded Mg–Gd–Y–Zn–Zr alloys filled with intragranular LPSO phases. Mater. Charact. 135, 76–83 (2018)

J.F. Wang, P.F. Song, S. Huang et al., High-strength and good-ductility Mg–RE–Zn–Mn magnesium alloy with long-period stacking ordered phase. Mater. Lett. 93, 415–418 (2013)

Y.F. Wang, Y.B. Zhang, W. Gao et al., Effect of Zr on the microstructures and mechanical properties of as-extruded Mg–2.3Zn–0.18Y–xZr alloys. Int. J. Mod. Phys. B 31, 16–19 (2017)

P. Cheng, Y.H. Zhao, R.P. Lu et al., Effect of Ti addition on the microstructure and mechanical properties of cast Mg–Gd–Y–Zn alloys. Mater. Sci. Eng. A 708, 482–491 (2017)

Y. Wang, W. Rong, Y.J. Wu et al., Effects of Mn addition on the microstructures and mechanical properties of the Mg–15Gd–1Zn alloy. J. Alloys Compd. 698, 1066–1076 (2017)

M. Jiang, X.L. Su, H.X. Li et al., The phase equilibria and thermal stability of the long-period stacking ordered phase in the Mg–Cu–Y system. J. Alloys Compd. 593, 141–147 (2014)

W.S. Chuang, C.H. Hsieh, J.C. Huang et al., Relation between sample size and deformation mechanism in Mg–Zn–Y 18R-LPSO single crystals. Intermetallics 91, 110–119 (2017)

J.F. Wang, S.Q. Gao, X.Y. Liu et al., Enhanced mechanical properties and degradation rate of Mg–Ni–Y alloy by introducing LPSO phase for degradable fracturing ball applications. J. Magn. Alloys 8(1), 127–133 (2020)

C. Xu, T. Nakata, K. Oh-ishi et al., Improving creep property of Mg–Gd–Zn alloy via trace Ca addition. Scr. Mater. 139, 34–38 (2017)

X.M. Zhang, J.L. Hu, L.Y. Ye et al., Effects of Si addition on microstructure and mechanical properties of Mg–8Gd–4Y–Nd–Zr alloy. Mater. Des. 43, 74–79 (2013)

X.F. Gu, T. Furuhara, L. Chen et al., Study on the planar segregation of solute atoms in Mg–Al–Gd alloy. Scr. Mater. 150, 45–49 (2018)

E.F. Emely, Principles of Magnesium Technology, 1st edn., (Pergamon Press, Oxford, 1966), pp.127–55

Q.M. Peng, H.W. Dong, L.D. Wang et al., Aging behavior and mechanical properties of Mg–Gd–Ho alloys. Mater. Charact. 59(8), 983–986 (2007)

L. Yang, Y. Huang, F. Feyerabend et al., Microstructure, mechanical and corrosion properties of Mg–Dy–Gd–Zr alloys for medical applications. Acta Biomater. 9(10), 8499–8508 (2013)

T. Kawabata, K. Matsuda, S. Ikeno et al., HRTEM observation of metastable phases in a Mg–15%Gd–6.4%Sc alloy. Mater. Trans. 51, 301–304 (2010)

X.B. Zheng, W.B. Du, Z.H. Wang et al., Remarkably enhanced mechanical properties of Mg–8Gd–1Er–0.5Zr alloy on the route of extrusion, rolling and aging. Mater. Lett. 212, 155–158 (2018)

Z.J. Yu, C. Xu, J. Meng et al., Effects of pre-annealing on microstructure and mechanical properties of as-extruded Mg–Gd–Y–Zn–Zr alloy. J. Alloys Compd. 729, 627–637 (2017)

K.Y. Zheng, J. Dong, X.Q. Zeng et al., Effect of thermo-mechanical treatment on the microstructure and mechanical properties of a Mg–6Gd–2Nd–0.5Zr alloy. Mater. Sci. Eng. A 454–455, 314–321 (2007)

X.L. Hou, Z.Y. Cao, L. Zhao et al., Microstructure, texture and mechanical properties of a hot rolled Mg–6.5Gd–1.3Nd–0.7Y–0.3Zn alloy. Mater. Des. 34, 776–781 (2011)

L. Zhang, M. Gong, L.M. Peng et al., Microstructure and strengthening mechanism of a thermomechanically treated Mg–10Gd–3Y–1Sn–0.5Zr alloy. Mater. Sci. Eng. A 565, 262–268 (2013)

J.J. Gao, J. Fu, N. Zhang et al., Structural features and mechanical properties of Mg–Y–Zn–Sn alloys with varied LPSO phases. J. Alloys Compd. 768, 1029–1038 (2018)

L. Ye, Y. Liu, D.S. Zhao et al., Effects of Sn on the microstructure and mechanical properties of a hot-extruded Mg–Zn–Y–Sn alloy. Mater. Sci. Eng. A 724, 121–130 (2018)

M.L. Fornasini, P. Manfrinetti, K.A. Gschneidner et al., GdMg5: a complex structure with a large cubic cell. Acta Crystallogr. C 42(2), 138–141 (1986)

R. Cottam, J. Robson, G. Lorimer et al., Dynamic recrystallization of Mg and Mg–Y alloys: crystallographic texture development. Mater. Sci. Eng. A 485, 375–382 (2008)

R.L. Goetz, Particle stimulated nucleation during dynamic recrystallization using a cellular automata model. Scr. Mater. 52(9), 851–856 (2005)

L. Zheng, C.M. Liu, L. Jin et al., Effect of hot-rolling on microstructures and mechanical properties of extruded Mg–6Gd–3.2Y–xZn–0.5Zr sheet. J. Mater. Eng. Perform. 22, 104–111 (2013)

W.T. Sun, X.G. Qiao, M.Y. Zheng et al., Altered ageing behaviour of a nanostructured Mg–8.2Gd–3.8Y–1.0Zn–0.4Zr alloy processed by high pressure torsion. Acta Mater. 151, 260–270 (2018)

C. Xu, M.Y. Zheng, K. Wu et al., Effect of ageing treatment on the precipitation behaviour of Mg–Gd–Y–Zn–Zr alloy. J. Alloys Compd. 550, 50–56 (2013)

X. Gao, S.M. He, X.Q. Zeng et al., Microstructure evolution in a Mg–15Gd–0.5Zr (wt%) alloy during isothermal aging at 250 °C. Mater. Sci. Eng. A 431(1), 322–327 (2006)

T. Honma, T. Ohkubo, S. Kamado et al., Effect of Zn additions on the age-hardening of Mg–2.0Gd–1.2Y–0.2Zr alloys. Acta Mat. 55(12), 4137–4150 (2007)

C. Xu, T. Nakata, X.G. Qiao et al., Ageing behavior of extruded Mg–8.2Gd–3.8Y–1.0Zn–0.4Zr (wt%) alloy containing LPSO phase and γ´ precipitates. Sci. Rep. 7, 43391 (2017)

K. Wen, K. Liu, Z.H. Wang et al., Effect of microstructure evolution on mechanical property of extruded Mg–12Gd–2Er–1Zn–0.6Zr alloys. J. Magn. Alloys 3(1), 23–28 (2015)

X. Liu, W.Y. Hu, Q.C. Le et al., Microstructures and mechanical properties of high performance Mg–6Gd–3Y–2Nd–0.4Zr alloy by indirect extrusion and aging treatment. Mater. Sci. Eng. A 612(26), 380–386 (2014)

R. Zhen, Y.S. Sun, F. Xue et al., Effect of heat treatment on the microstructures and mechanical properties of the extruded Mg–11Gd–1Zn alloy. J. Alloys Compd. 550, 273–278 (2013)

R.G. Li, J.F. Nie, G.J. Huang et al., Development of high-strength magnesium alloys via combined processes of extrusion, rolling and ageing. Scr. Mater. 64(10), 950–953 (2011)

X.B. Liu, R.S. Chen, E.H. Han et al., Effects of ageing treatment on microstructures and properties of Mg–Gd–Y–Zr alloys with and without Zn additions. J. Alloys Compd. 465(1), 232–238 (2007)

Acknowledgements

This work is supported by the Research and development project of scientific and technological achievements in provincial universities of Heilongjiang provincial department of education(Grant number TSTAU-R2018003), Open research fund of state key laboratory of metastable materials science and technology of Yanshan university (Grant number 202002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, Z., Yu, Y., Qian, J. et al. Fabrication of High-Strength Mg–Gd–Nd–Zn–Sn–Zr Alloy via Extrusion and Aging. Met. Mater. Int. 27, 4182–4194 (2021). https://doi.org/10.1007/s12540-020-00859-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00859-7