Abstract

In this study, the wear behaviors of the solution-treated and as-extruded SiCp /AZ91D metal matrix composites with different sizes and volume fractions of SiC particles were systematically investigated under different wear test parameters. The SiC particles exhibited a typical necklace-type distribution in the solution-treated composites and a homogeneous distribution in the as-extruded composites. Wear tests results showed that the wear rates of the as-extruded composites were lower than that of the solution-treated composites almost under all testing conditions and with the same SiC size and volume fraction. However, the dominant wear mechanisms for these two types of composites were different. The typical necklace-type distribution of SiCp in the solution-treated composites could effectively promote the occurrence of delamination owing to the weak bonding between SiCp and matrix in the particle aggregated regions. By contrast, as the bond between disperse SiCp and matrix was enhanced, the homogeneous distribution of SiCp in the as-extruded composites could promote the occurrence of adhesion and prevent the occurrence of delamination. Moreover, a higher applied load and higher volume fraction of SiCp obviously promoted the progress of delamination for the solution-treated composites, while the extent of the adhesive wear for the as-extruded composites was mainly associated with the increase of the applied load, sliding velocity and SiC particle size.

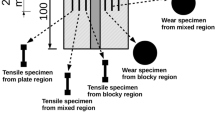

Graphic abstract

Similar content being viewed by others

References

X.J. Wang, D.K. Xu, R.Z. Wu, X.B. Chen, Q.M. Peng, L. Jin, Y.C. Xin, Z.Q. Zhang, Y. Liu, X.H. Chen, G. Chen, K.K. Deng, H.Y. Wang, J. Mater. Sci. Technol. 34, 245 (2018)

J.P. Sun, B.Q. Xu, Z.Q. Yang, H. Zhou, J. Han, Y.N. Wu, D. Song, Y.C. Yuan, X.R. Zhuo, H. Liu, A.B. Ma, J. Alloy. Comp. 817, 152688 (2020)

K. Lu, Materials science. The future of metals. Science 328, 319 (2010)

L.S. Wang, J.H. Jiang, T. Yuan, Q.Y. Xie, H. Liu, A.B. Ma, Met. Mater. Int. 26, 551 (2020)

Y. Sun, B.P. Zhang, Y. Wang, L. Geng, X.H. Jiao, Mater. Des. 34, 58 (2012)

S.Q. Yin, W.C. Duan, W.H. Liu, L. Wu, J.M. Yu, Z.L. Zhao, M. Liu, P. Wang, J.Z. Cui, Z.Q. Zhang, Corros. Sci. (2019). https://doi.org/10.1016/j.corsci.2019.108419

H. Liu, J. Ju, X.W. Yang, J.L. Yan, D. Song, J.H. Jiang, A.B. Ma, J. Alloy. Compd. 704, 509 (2017)

H. Liu, H. Huang, J. Sun, C. Wang, J. Bai, A. Ma, X. Chen, Acta Metall. Sin. (Engl. Lett.) 32, 269 (2018).

F. Zhong, H.J. Wu, Y.L. Jiao, R.Z. Wu, J.H. Zhang, L.G. Hou, M.L. Zhang, J. Mater. Sci. Technol. 39, 124 (2020)

B.J. Wang, D.K. Xu, S.D. Wang, L.Y. Sheng, R.C. Zeng, E.H. Han, Inter. J. Fatigue 120, 46 (2019)

H. Liu, J. Bai, K. Yan, J.L. Yan, A.B. Ma, J.H. Jiang, Mater. Des. 93, 9 (2016)

L.Y. Chen, J.Q. Xu, H. Choi, M. Pozuelo, X. Ma, S. Bhowmick, J.M. Yang, S. Mathaudhu, X.C. Li, Nature 528, 539 (2015)

B. Selvam, P. Marimuthu, R. Narayanasamy, V. Anandakrishnan, K.S. Tun, M. Gupta, M. Kamaraj, Mater. Des. 58, 475 (2014)

L.J. Huang, L. Geng, H.X. Peng, Prog. Mater. Sci. 71, 93 (2015)

M.E. Turan, H. Zengin, Y. Sun, Met. Mater. Int. 26, 541 (2020)

D.H. Cho, J.H. Nam, B.W. Lee, S.O. Yim, I.M. Park, Met. Mater. Int. 22, 332 (2016)

B.N. Sahoo, S.K. Panigrahi, Tribo. Int. 135, 463 (2019)

S. García-Rodríguez, B. Torres, A. Maroto, A.J. López, E. Otero, J. Rams, Wear 390–391, 1 (2017)

S. Suresha, B.K. Sridhara, Compos. Sci. Technol. 70, 1652 (2010)

B. Saleh, J.H. Jiang, A.B. Ma, D. Song, D.H. Yang, Q. Xu, Met. Mater. Int. 26, 933 (2020)

M.B. Karamis, A.A. Cerit, B. Selcuk, F. Nair, Wear 289, 73 (2012)

L.Q. Wu, R.Z. Wu, L.G. Hou, J.H. Zhang, M.L. Zhang, J. Alloy. Compd. 750, 530 (2018)

K.K. Deng, C.J. Wang, K.B. Nie, X.J. Wang, Acta Metall. Sin. (Engl. Lett.) 32, 413 (2019).

J. Hashim, L. Looney, M.S.J. Hashmi, J. Mater. Process. Technol. 93, 1 (1999)

A. Luo, Metall. Mater. Trans. A 26, 2445 (1995)

X.J. Wang, X.S. Hu, W.Q. Liu, J.F. Du, K. Wu, Y.D. Huang, M.Y. Zheng, Mater. Sci. Eng. A 682, 491 (2017)

J. Chen, C.G. Bao, Y. Wang, J.L. Liu, C. Suryanarayana, Acta Metall. Sin. (Engl. Lett.) 28, 1354 (2015).

X.J. Wang, L. Xu, X.S. Hu, K.B. Nie, K.K. Deng, K. Wu, M.Y. Zheng, Mater. Sci. Eng. A 528, 6387 (2011)

S.J. Shang, K.K. Deng, K.B. Nie, J.C. Li, S.S. Zhou, F.J. Xu, J.F. Fan, Mater. Sci. Eng. A 610, 243 (2014)

M.T. Parizi, A. Habibolahzadeh, G.R. Ebrahimi, Mater. Chem. Phys. 199, 485 (2017)

ASTM G190-15, Standard Guide for Developing and Selecting Wear Tests, (ASTM International, West Conshohocken, PA, 2015), https://www.astm.org

ASTM G99-17, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, (ASTM International, West Conshohocken, PA, 2017), https://www.astm.org

ASTM E10-18, Standard Test Method for Brinell Hardness of Metallic Materials, (ASTM International, West Conshohocken, PA, 2018), https://www.astm.org

A.S. Verma, A. Singh, D. Kumar, A.K. Dubey, A.C.S. Biomater, Sci. Eng. 6, 3055 (2020)

A.S. Verma, D. Kumar, A.K. Dubey, Ceram. Int. 44, 16119 (2018)

J.P. Sun, Z.Q. Yang, J. Han, T. Yuan, D. Song, Y.N. Wu, Y.C. Yuan, X.R. Zhuo, H. Liu, A.B. Ma, J. Alloy. Compd. 780, 443 (2019)

G. Garcés, P. Pérez, P. Adeva, Scr. Mater. 52, 615 (2005)

K. Hokkirigawa, K. Kato, Tribol. Int. 21, 51 (1988)

Z.F. Zhang, L.C. Zhang, Y.W. Mai, Wear 194, 38 (1996)

N.P. Suh, Wear 25, 111 (1973)

N.P. Suh, Wear 44, 1 (1977)

J. Archard, J. Appl. Phys. 24, 981 (1953)

B. Venkataraman, G. Sundararajan, Acta Mater. 44, 451 (1996)

L. Cao, Y. Wang, C. Yao, Wear 140, 273 (1990)

Q. Zhao, Y. Liang, Z. Zhang, X. Li, L. Ren, Metals 6, 227 (2016)

C.Y.H. Lim, S.C. Lim, A. Gupta, Wear 255, 629 (2003)

C. Kanchanomai, B. Saengwichian, A. Manonukul, Wear 267, 1665 (2009)

X. Cao, W.L. Huang, C.G. He, J.F. Peng, J. Guo, W.J. Wang, Q.Y. Liu, M.H. Zhu, Wear 348–349, 98 (2016)

H. Mishina, A. Hase, Wear 432–433, 202936 (2019)

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (B200202131), the National Natural Science Foundation of China (Grant Nos. 51871074, 51971078 and 51671066) and the Project National United Engineering Laboratory for Advanced Bearing Tribology, Henan University of Science and Technology (Grant No. 201911).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, H., Lu, N., Wang, X. et al. Different Tribological Behaviors of SiCp/AZ91 Composites Induced by Tailoring the Distribution of SiC Particles. Met. Mater. Int. 27, 556–569 (2021). https://doi.org/10.1007/s12540-020-00780-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00780-z