Abstract

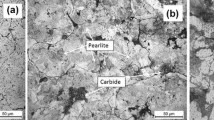

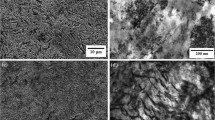

This study investigates the variations in the microstructure and mechanical properties of a medium-carbon high-Si steel (Fe–0.55C–2.3Si) during graphitization heat treatment and subsequent quenching and tempering heat treatment. The microstructure comprising ferrite and pearlite of the as-rolled sample changes to a more ductile microstructure with fine graphites uniformly dispersed in the ferrite matrix after graphitization treatment. These formed graphites are completely dissolved into the ferrite matrix after austenitizing treatment at 900 °C, but preexisting graphite positions remains as voids. The average size and number density of voids are nearly identical to those of the pre-existed graphites. The subsequent tempering treatments at 300 °C and 500 °C cause little changes in the size and number of the voids. Therefore, the formation of voids in the quenched-and-tempered samples is directly related to the graphites of the initial graphitized sample. The average size of graphites and voids is inversely proportional to the logarithm of their number density. When the as-rolled sample is completely graphitized, its ultimate tensile strength decreases from 928 to 494 MPa and its tensile elongation increases from 20.7 to 34.0%, indicating that the medium-carbon high-Si steel is substantially softened through graphitization treatment. Moreover, subsequent quenching and tempering treatment at 500 °C increases its ultimate tensile strength to 1168 MPa. The drastic softening through graphitization and significant strengthening through subsequent quenching and tempering exhibit the possibility of the application of medium-carbon, high-Si steels as cold heading quality steels for manufacturing fastener components.

Graphic abstract

Similar content being viewed by others

References

G. Krauss, Steels: Processing, Structure, and Performance, 3rd edn. (ASM International, Cleveland, 2005)

L.I. Zhuang, W.U. Di, L. Wei, J. Iron Steel Res. Int. 19, 64 (2012)

P.F. Thomason, Proc. Inst. Mech. Eng. 184, 875 (1969)

H. Kim, M. Kang, C.M. Bae, H.S. Kim, S. Lee, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 45, 1294 (2014)

Z. Li, J. Iron Steel Res. Int. 16, 43 (2009)

M.J. Harrigan, O.D. Sherby, Mater. Sci. Eng. 7, 177 (1971)

K.G. Ata, S.A. Meisam, J. Iron Steel Res. Int. 17, 45 (2010)

H.M. Seok, K.H. Tae, Int. J. Chem. Nucl. Metall. Mater. Eng. 8, 115 (2014)

K.D. Woo, J. Korean Soc. Heat Treat. 17, 117 (2004)

A.A. Zhukov, Met. Sci. Heat Treat. 26, 849 (1984)

P. Rubin, R. Larker, E. Navara, M.L. Antti, Metallogr. Microstruct. Anal. 7, 587 (2018)

K. Banerjee, T. Venugopalan, Mater. Sci. Technol. 24, 1174 (2008)

T. Iwamoto, T. Hoshino, A. Matsuzaki, K. Amano, ISIJ Int. 42, S77 (2002)

K. He, H.R. Daniels, A. Brown, R. Brydson, D.V. Edmonds, Acta Mater. 55, 2919 (2007)

Y.J. Kim, S.W. Bae, N.S. Lim, S.H. Park, Mater. Sci. Eng. A (2020). https://doi.org/10.1016/j.msea.2020.139392

M. Okonogi, M. Hashimura, H. Kanisawa, S. Katayama, Nippon Steel Tech. Rep. 80, 16 (1999)

A. Inam, R. Brydson, D.V. Edmonds, Mater. Charact. 106, 86 (2015)

S.A. Rounaghi, A.R. Kiani-Rashid, Phase Trans. 84, 981 (2011)

J.X. Gao, B.Q. Wei, D.D. Li, K. He, Mater. Charact. 118, 1 (2016)

H.L. Kim, S.H. Bang, J.M. Choi, N.H. Tak, S.W. Lee, S.H. Park, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00500-2

F. Najafkhani, H. Mirzadeh, M. Zamani, Met. Mater. Int. 25, 1039 (2019)

M. Kalantar, H. Najafi, M.R. Afshar, Met. Mater. Int. 25, 229 (2019)

S.K. Basantia, A. Bhattacharya, N. Khutia, D. Das, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00519-5

W. Shyam, ASTM E8/E8M-11 Standard Test Methods for Tension Testing of Metallic Materials (ASTM, Philadelphia, 2011)

H. Sueyoshi, K. Suenaga, Nippon Kinzoku Gakkai-si 43, 333 (1979)

H. Sueyoshi, K. Suenaga, R. Tanaka, Nippon Kinzoku Gakkai-si 49, 20 (1985)

K. Oikawa, H. Mitsui, T. Ebata, T. Takiguchi, T. Shimizu, K. Ishikawa, T. Noda, M. Okabe, K. Ishida, ISIJ Int. 42, 806 (2002)

A. Rosen, A. Taub, Acta Metall. 10, 501 (1962)

Y. Yoshida, L. Cisar, S. Kamado, Y. Kojima, Mater. Trans. 44, 468 (2003)

F.S. Buffington, K. Hirano, M. Cohen, Acta Metall. 9, 434 (1961)

J. Ågren, Acta Metall. 30, 841 (1982)

P. Haušild, C. Berdin, P. Bompard, N. Verdière, Int. J. Press. Vessel. Pip. 78, 607 (2001)

X. Teng, H. Mae, Y. Bai, T. Wierzbicki, Eng. Fract. Mech. 76, 983 (2009)

P.F. Liu, J.Y. Zheng, J. Fail. Anal. Prev. 10, 212 (2010)

S.K. Dhua, A. Ray, D.S. Sarma, Mater. Sci. Eng. A 318, 197 (2001)

Y. Kimura, T. Inoue, K. Tsuzaki, J. Alloys Compd. 577S, S538 (2013)

A. Ohmori, S. Torizuka, K. Nagai, ISIJ Int. 44, 1063 (2004)

W.S. Lee, T.T. Su, J. Mater. Process. Technol. 87, 198 (1999)

A. Leiro, A. Roshan, K.G. Sundin, E. Vuorinen, B. Prakash, Acta Metall. Sin. (Engl. Lett.) 27, 55 (2014)

M.S. Rashid, B.V.N. Rao, Metall. Trans. A 13, 1679 (1982)

X. Xiong, F. Yang, X. Zou, J. Suo, J. Nucl. Mater. 430, 114 (2012)

K.S. See, T.A. Dean, J. Mater. Process. Technol. 69, 58 (1997)

L. Yuan, W. Shi, R. Shivpuri, F. Xu, D. Shan, J. Mater. Process. Technol. 243, 456 (2017)

B. Karlsson, G. Linden, Mater. Sci. Eng. 17, 209 (1975)

Acknowledgements

This work was supported by grants from Pohang Iron and Steel Company (POSCO) (No. 2018Z022) and National Research Foundation of Korea (NRF) funded by the Korean government (MSIP, South Korea) (No. 2019R1A2C1085272).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, Y.J., Bae, S.W., Lim, N.S. et al. Evolution of Microstructure and Mechanical Properties of Graphitized Fe–0.55C–2.3Si Steel During Quenching and Tempering Treatment. Met. Mater. Int. 27, 3730–3739 (2021). https://doi.org/10.1007/s12540-020-00743-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00743-4