Abstract

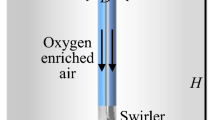

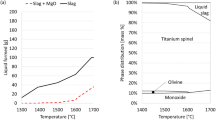

A Mitsubishi process, which pertains to continuous Cu production, involves a smelting furnace, cleaning furnace, and converting furnace connected in series. One of the main issues pertaining to the smelting furnace is the frequent interruption of operations required to allow the inspection and replacement of lances, because lances are frequently fractured. The present study was aimed at modifying the operating conditions of the smelting furnace to suppress lance fractures. A numerical model was developed to simulate the transport phenomena in the furnace, including multi-phase behaviors. The simulation results showed that the lances were exposed to a severely erosive atmosphere with high temperatures. Further calculation indicated that raising the positions of the lances could lower the temperature of the lances, and reducing the occurrence of splashed melt, which contains erosive sulfides. The smelting furnace was operated under the conditions of the raised lance height and attentively monitored for several months. It was confirmed that by implementing such a change of the lance heights, the occurrence of lance failures has been considerably reduced without notably affecting the reaction ability of the smelting furnace.

Graphic Abstract

These slides can be retrieved under Electronic Supplementary Material.

Similar content being viewed by others

References

J.-H. Park, S.-S. Park, X.-F. Han, K.-W. Yi, Met. Mater. Int. 22, 118 (2016)

E. Kimura, ISIJ Int. 23, 522 (1983)

J.-S. Chang, H.-Y. Sohn, Metall. Mater. Trans. B 43B, 787 (2012)

Y.-B. Hahn, H.-Y. Sohn, Metall. Mater. Trans. B 21B, 945 (1990)

M. Goto, E. Oshima, M. Hayashi, JOM 50, 60 (1998)

M. Goto, The Mitsubishi continuous process—operation and design (Mitsubishi Materials Corporation, Tokyo, 1988)

M. Goto, M. Hayashi, The Mitsubishi continuous process: metallurgical Commentary, 2nd edn. (Mitsubishi Materials Corporation, Tokyo, 2002)

W.G. Davenport, E.H. Partelpoeg, Flash smelting: analysis, control and optimization, 1st edn. (Pergamon Press, Oxford, 1987)

Y. Takamiya, Y. Endo, S. Hosokawa, Refractories handbook (American Ceramic Society, Japan, 1998)

D.R. Gaskell, An introduction to transport phenomena in materials engineering, 2nd edn. (Momentum Press, New York, 2012)

I. Barin, Thermochemical data of pure substances, 3rd edn. (VCH, New York, 1995)

Y. Shiraishi, K. Ikeda, A. Tamura, T. Saitô, Trans. JIM 19, 264 (1978)

T. Shibasaki, M. Hayashi, JOM 43, 20 (1991)

Z. Yang, T.-H. Shih, AIAA J. 31, 1191 (1993)

M. Alam, J. Naser, G. Brooks, A. Fontana, ISIJ Int. 52, 1026 (2012)

S.A. Morsi, A.J. Alexander, J. Fluid Mech. 55, 193 (1972)

W.G. Davenport, M. King, M. Schlesinger, A.K. Biswas, Extractive metallurgy of copper, 4th edn. (Elsevier, Amsterdam, 2002)

Z. Asaki, T. Taniguchi, M. Hayashi, JOM 53, 25 (2001)

D.J. Young, S. Watson, Oxid. Met. 44, 239 (1995)

I.-K. Choi, Met. Mater. Int. 2, 245 (1996)

R.D. Monteiro, J.V.D. Wetering, B. Krawczyk, D. Engelberg, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00403-2

B.S. Bokstein, B. Straumal, Diffusion, segregation and stresses in materials (Trans Tech Publications Ltd, Stafa, 2003)

Acknowledgements

We acknowledge LS-Nikko Co. for supporting the present study and permitting to publish.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lim, SM., Park, SS. & Yi, KW. Extension of Lance Life by Change of Height of Lances in the Smelting Furnace of Mitsubishi Process. Met. Mater. Int. 27, 3721–3729 (2021). https://doi.org/10.1007/s12540-020-00712-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00712-x