Abstract

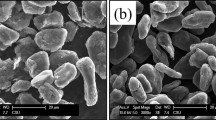

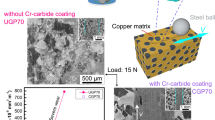

Neoteric copper/sintered–carbon (Cu/SC) composites for pantograph sliders were produced with the method of pressure infiltration. The friction and wear behaviors with or without current and mechanical performances of Cu/SC composites showed that graphite acted dual effects on Cu/SC, that is, with the addition content of graphite, the electrical conductivity of carbon matrices increased while the mechanical properties decreased. The friction coefficient and the wear rate decreased with the increase of the graphite content on dry sliding wear test, and the minimum friction coeffient was only 0.096. Meanwhile, the friction coefficient increased first and then decreased with the current increse, while the wear rate just kept increasing. Scanning electron micrographs revealed a grid-like distribution of copper in the Cu/SC composites. Futhermore, through observation and analysis, it was found that Cu/SC composites of pantograph sliders were dominated by adhesive wear and corrosive wear respectively under two different currents of 5 A and 15 A.

Graphic Abstract

Copper was uniformly distributed in the carbon matrix in a spatial network structure, almost filling the pores in the matrix, greatly improving the overall combined by mechanical interlocking, and the compressive strength is up to 159.81 MPa.

Similar content being viewed by others

References

Y. Kubota, S. Nagasaka, T. Miyauchi, C. Yamashita, H. Kakishima, Sliding wear behavior of copper alloy impregnated C/C composites under an electrical current. Wear 302(1–2), 1492–1498 (2013). https://doi.org/10.1016/j.wear.2012.11.029

S. Ma, E. Xu, Z. Zhu, Q. Liu, S. Yu, J. Liu, H. Zhong, Y. Jiang, Mechanical and wear performances of aluminum/sintered–carbon composites produced by pressure infiltration for pantograph sliders. Powder Technol. 326, 54–61 (2018). https://doi.org/10.1016/j.powtec.2017.12.027

T. Ding, G.X. Chen, J. Bu, W.H. Zhang, Effect of temperature and arc discharge on friction and wear behaviours of carbon strip/copper contact wire in pantograph–catenary systems. Wear 271(9–10), 1629–1636 (2011). https://doi.org/10.1016/j.wear.2010.12.031

X.C. Ma, G.Q. He, D.H. He, C.S. Chen, Z.F. Hu, Sliding wear behavior of copper–graphite composite material for use in maglev transportation system. Wear 265(7–8), 1087–1092 (2008). https://doi.org/10.1016/j.wear.2008.02.015

W. Ma, J. Lu, Effect of sliding speed on surface modification and tribological behavior of copper-graphite composite. Tribol. Lett. 41(2), 363–370 (2011). https://doi.org/10.1007/s11249-010-9718-x

H.J. Yang, G.X. Chen, G.Q. Gao, G.N. Wu, W.H. Zhang, Experimental research on the friction and wear properties of a contact strip of a pantograph–catenary system at the sliding speed of 350 km/h with electric current. Wear 332–333, 949–955 (2015). https://doi.org/10.1016/j.wear.2014.11.004

J.M. Casstevens, H.G. Rylander, Z. Eliezer, Influence of high velocities and high current densities on the friction and wear behavior of copper-graphite brushes. Wear 48(1), 121–130 (1978). https://doi.org/10.1016/0043-1648(78)90142-4

P. Wang, H. Zhang, J. Yin, X. Xiong, C. Tan, C. Deng, Z. Yan, Wear and friction behaviours of copper mesh and flaky graphite- modified carbon/carbon composite for sliding contact material under electric current. Wear 380–381, 59–65 (2017). https://doi.org/10.1016/j.wear.2017.02.045

H. Yang, R. Luo, S. Han, M. Li, Effect of the ratio of graphite/pitch coke on the mechanical and tribological properties of copper–carbon composites. Wear 268(11–12), 1337–1341 (2010). https://doi.org/10.1016/j.wear.2010.02.007

L.H. Cui, R.Y. Luo, D.H. Ma, Carbon Fiber Reinforced Carbon-Al-Cu Composite for Friction Material. Materials 11(4), 16 (2018). https://doi.org/10.3390/ma11040538

J. Yin, H.B. Zhang, C. Tan, X. Xiong, Effect of heat treatment temperature on sliding wear behaviour of C/C-Cu composites under electric current. Wear 312(1–2), 91–95 (2014). https://doi.org/10.1016/j.wear.2014.01.001

R.K. Gautam, K.K. Kar, Synthesis and properties of highly conducting natural flake graphite/phenolic resin composite bipolar plates for PEM fuel cells. Adv. Compos. Lett. 25(4), 87–97 (2016)

S. Kubo, K. Kato, Effect of arc discharge on the wear rate and wear mode transition of a copper-impregnated metallized carbon contact strip sliding against a copper disk. Tribol. Int. 32(7), 367–378 (1999). https://doi.org/10.1016/s0301-679x(99)00062-6

H. Nagasawa, K. Kato, Wear mechanism of copper alloy wire sliding against iron-base strip under electric current. Wear 216(2), 179–183 (1998). https://doi.org/10.1016/s0043-1648(97)00162-2

S. Kubo, K. Kato, Effect of arc discharge on wear rate of Cu-impregnated carbon strip in unlubricated sliding against Cu trolley under electric current. Wear 216(2), 172–178 (1998). https://doi.org/10.1016/s0043-1648(97)00184-1

S.F. Moustafa, S.A. El-Badry, A.M. Sanad, B. Kieback, Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders. Wear 253(7–8), 699–710 (2002). https://doi.org/10.1016/s0043-1648(02)00038-8

A. Sharma, B. Ahn, Dry Sliding Wear Behavior of Sn and NiSn Overlays on Cu Connectors. Tribol. Lett. 66(4), 12 (2018). https://doi.org/10.1007/s11249-018-1089-8

E. Xu, J. Huang, Y. Li, Z. Zhu, M. Cheng, D. Li, H. Zhong, J. Liu, Y. Jiang, Graphite cluster/copper-based powder metallurgy composite for pantograph slider with well-behaved mechanical and wear performance. Powder Technol. 344, 551–560 (2019). https://doi.org/10.1016/j.powtec.2018.12.059

B. Kong, T.X. Fan, J.M. Ru, Improved wetting and thermal properties of graphite-Cu composite by Cr-solution immersion method. Diam. Relat. Mat. 65, 191–197 (2016). https://doi.org/10.1016/j.diamond.2016.03.024

A.R. Riahi, A.T. Alpas, The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites. Wear 250–251, 1396–1407 (2001). https://doi.org/10.1016/s0043-1648(01)00796-7

T. Ding, G.X. Chen, X. Wang, M.H. Zhu, W.H. Zhang, W.X. Zhou, Friction and wear behavior of pure carbon strip sliding against copper contact wire under AC passage at high speeds. Tribol. Int. 44(4), 437–444 (2011). https://doi.org/10.1016/j.triboint.2010.11.022

M. Kestursatya, J.K. Kim, P.K. Rohatgi, Wear performance of copper–graphite composite and a leaded copper alloy. Mater. Sci. Eng. A 339(1–2), 150–158 (2003). https://doi.org/10.1016/s0921-5093(02)00114-4

N.P. Suh, The delamination theory of wear. Wear 25(1), 111–124 (1973). https://doi.org/10.1016/0043-1648(73)90125-7

Y. Feng, M. Zhang, Y. Xu, Effect of the electric current on the friction and wear properties of the CNT-Ag-G composites. Carbon 43(13), 2685–2692 (2005). https://doi.org/10.1016/j.carbon.2005.05.029

L. Dong, G.X. Chen, M.H. Zhu, Z.R. Zhou, Wear mechanism of aluminum-stainless steel composite conductor rail sliding against collector shoe with electric current. Wear 263, 598–603 (2007). https://doi.org/10.1016/j.wear.2007.01.130

Y.Y. Zhang, Y.Z. Zhang, S.M. Du, C.F. Song, Z.H. Yang, B. Shangguan, Tribological properties of pure carbon strip affected by dynamic contact force during current-carrying sliding. Tribol. Int. 123, 256–265 (2018). https://doi.org/10.1016/j.triboint.2017.12.032

Acknowledgements

This work was supported by grants from the National Natural Science Foundation of China (Grant No. U1632151), the Key Research and Development Project of Anhui Province of China (Grant No. 1704a0902023).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, Y., Huang, J., Wang, M. et al. Microstructure and Current Carrying Wear Behaviors of Copper/Sintered–Carbon Composites for Pantograph Sliders. Met. Mater. Int. 27, 3398–3408 (2021). https://doi.org/10.1007/s12540-020-00652-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00652-6