Abstract

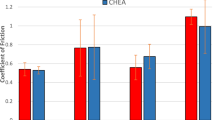

Tribological properties of AlCoCrCuFeNi high-entropy alloy were studied after annealing at various temperatures. X-ray diffraction, scanning electron microscopy, energy dispersive spectroscopy, microhardness tester and pin-on-disc tribometer analyses were performed to reveal the microstructure, composition, microhardness and tribological behavior variations. With the heat treatment temperature increasing, time taken for friction coefficient going through the rapidly dropping down and then into the stable period increases, the white sheets structures and their size in dendrite area of the AlCoCrCuFeNi alloy becomes bigger, however BCC content declined dramatically. Then, the average friction coefficient of the AlCoCrCuFeNi/Si3N4 sliding friction pair increase from 0.037 to 0.115, and the pin wear loss increase from 3 to 11 µm.

Graphic Abstract

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight et al., Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377, 213–218 (2004)

Y.Y. Chen, U.T. Hong, J.W. Yeh et al., Selected corrosion behaviors of a Cu0.5NiAlCoCrFeSi bulk glassy alloy in 288 °C high-purity water. Scr. Mater. 12(54), 1997–2001 (2006)

A. Takeuchi, N. Chen, J.W. Yeh et al., Pd20Pt20Cu20Ni20P20 high-entropy alloy as a bulk metallic glass in the centimeter. Intermetallics 10(19), 1546–1554 (2011)

Z.P. Lu, H. Wang, J.W. Yeh et al., An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics 66, 67–76 (2015)

J.W. Yeh, S.K. Chen, S.J. Lin et al., Nanostructure high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004)

S. Singh, N. Wanderk, K. Kiefer et al., Effect of decomposition of the Cr–Fe–Co rich phase of AlCoCrCuFeNi high entropy alloy on magnetic properties. Ultramicroscopy 111, 619–622 (2011)

N.A.P.K. Kumar, C. Li, K.J. Leonard et al., Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation. Acta Mater. 113, 230–244 (2016)

B. Ren, S.Q. Yan, R.F. Zhao et al., Structure and properties of (AlCrMoNiTi)Nx and (AlCrMoZrTi)Nx films by reactive RF sputtering. Surf. Coat. Technol. 235, 764–772 (2013)

T. Borkar, B. Gwalani, D. Choudhuri et al., Hierarchical multi-scale microstructural evolution in an as-cast Al2CuCrFeNi2 complex concentrated alloy. Intermetallics 71, 31–42 (2016)

S.G. Ma, J.W. Qiao, Z.H. Wang et al., Microstructural features and tensile behaviors of the Al0.5CrCuFeNi2 high-entropy alloys by cold rolling and subsequent annealing. Mater. Des. 88, 1057–1062 (2015)

B. Schuh, F. Mendez-Martin, B. Völker et al., Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 96, 258–268 (2015)

H. Zhang, Y. Pan, Y.Z. He, Effects of annealing on the microstructure and properties of 6FeNiCoCrAlTiSi high-entropy alloy coating prepared by laser cladding. J. Therm. Spray Technol. 20(5), 1049–1055 (2011)

M.H. Chuang, M.H. Tsai, J.W. Yeh et al., Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 59, 6308–6317 (2011)

T.W. Lu, C.S. Feng, Z. Wang et al., Microstructures and mechanical properties of CoCrFeNiAl0.3 high-entropy alloy thin films by pulsed laser deposition. Appl. Surf. Sci. 494(15), 72–79 (2019)

W.B. Liao, S. Lan, L.B. Gao et al., Nanocrystalline high-entropy alloy (CoCrFeNiAl0.3) thin-film coating by magnetron sputtering. Thin Solid Films 638(30), 383–388 (2017)

A.S. Gohardani, J. Stanojev, A. Demaire et al., Green space propulsion: opportunities and prospects. Prog. Aerosp. Sci. 71, 128–149 (2014)

H. Kang, D. Jang, S. Kwon, Demonstration of 500 N scale bipropellant thruster using non-toxic hypergolic fuel and hydrogen peroxide. Aerosp. Sci. Technol. 49, 209–214 (2016)

R. Gostowski, Isothermal calorimetric observations of the effect of welding on compatibility of stainless steels with high-test hydrogen peroxide propellant. Thermochim. Acta 404(1), 279–281 (2003)

Y. Yu, W.M. Liu, T.B. Zhang et al., Microstructure and tribological properties of AlCoCrFeNiTi0.5 high-entropy alloy in hydrogen peroxide solution. Metall. Mater. Trans. A 45(1), 201–207 (2014)

H.T. Duan, Y. Wu, M. Hua et al., Tribological properties of AlCoCrFeNiCu high-entropy alloy in hydrogen peroxide solution and in oil lubricant. Wear 297, 1045–1051 (2013)

R.S. Ganji, P.S. Karthik, K.B.S. Rao, K.V. Rajulapati, Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro- and nanoindentation methods. Acta Mater. 125, 58–68 (2017)

C.D. Gómez-Esparza, R. Peréz-Bustamante, J.M. Alvarado-Orozco et al., Microstructural evaluation and nanohardness of an AlCoCuCrFeNiTi high-entropy alloy. Int. J. Miner. Metall. Mater. 26(5), 634–641 (2019)

Y.Y. Liu, Z. Chen, J.C. Shi et al., The effect of Al content on microstructures and comprehensive properties in AlxCoCrCuFeNi high entropy alloys. Vacuum 161, 143–149 (2019)

R. Kulkarni, B.S. Murty, V. Srinivas, Study of microstructure and magnetic properties of AlNiCo(CuFe) high entropy alloy. J. Alloys Compd. 746, 194–199 (2018)

A. Munitz, M.J. Kaufman, M. Nahmany et al., Microstructure and mechanical properties of heat treated Al1.25CoCrCuFeNi high entropy alloys. Mater. Sci. Eng. A 714, 146–159 (2018)

A. Takeuchi, A. Inoue, Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 46(12), 2817–2829 (2005)

C.C. Tung, J.W. Yeh, T.T. Shun et al., On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater. Lett. 61, 1–5 (2007)

C.J. Tong, M.R. Chen, J.W. Yeh et al., Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall. Mater. Trans. A 36(5), 1263–1271 (2005)

J.M. Wu, S.J. Lin, J.W. Yeh et al., Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 261, 513–519 (2006)

K.B. Zhang, Z.Y. Fu, J.Y. Zhang et al., Nanocrystalline CoCrFeNiCuAl high-entropy solid solution synthesized by mechanical alloying. J. Alloys Compd. 485, 31–34 (2009)

R.E. Reed-Hill, R. Abbaschian, Physical Metallurgy Principles, 3rd edn. (PWS-KENT, Boston, 1994), pp. 140–146

T. Courtney, Mechanical Behavior of Materials (McGraw-Hill, New York, 1990), pp. 173–184

G.E. Dieter, Mechanical Metallurgy (SI Metric Editions), vol. 117–121 (McGraw-Hill, New York, 1988), pp. 208–212

M.M. Khruschov, Principles of abrasive wear. Wear 28, 69–88 (1974)

C.P. Hu, Y.L. Zhao, J.P. Wang et al., Tribological properties of AlCoCrFeNiCu high-entropy alloy in high concentration hydrogen peroxide. Tribology 31(5), 439–446 (2011)

Acknowledgements

The authors express their gratitude to the financial support of the National Natural Science Foundation of China (Nos. 51275361, 51505341) and the help in performing the experimental works by Mr. Hu Chengping, Assistant Engineer.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, X.S., Li, J., Jin, Y.L. et al. Heat Treatment Influence on Tribological Properties of AlCoCrCuFeNi High-Entropy Alloy in Hydrogen Peroxide-Solution. Met. Mater. Int. 26, 1286–1294 (2020). https://doi.org/10.1007/s12540-019-00532-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00532-8