Abstract

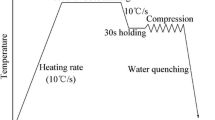

In this paper, to research the dynamic recrystallization (DRX) behavior of a high-strength steel (34CrNiMo6), hot compression tests were carried on Gleeble-1500D thermo-mechanical simulator within the different temperatures and strain rates. After hot compression tests, the microstructures of specimens were observed by optical microscope. Based on Kocks and Mecking mathematics model (KM), the DRX kinetic model was established by the flow stress curves during hot deformation. Meanwhile, a grain size model was established by measuring microstructure. Furthermore, combined with the material kinetic model and grain size model, a rigid–plastic finite element simulation was built to analyze the microstructural behavior of 34CrNiMo6 steel during the uniaxial hot compression. The results indicate that the simulation results are in good agreement with the experimental data. The DRX model had an accurately predictive capability for the hot compression process, which could provide a theoretical guidance and process optimization for metal forming processes.

Graphic Abstract

Similar content being viewed by others

References

Q.G. Meng, C.G. Bai, D.S. Xu, J. Mater. Sci. Technol. 34, 679–688 (2018)

T. Zhong, K.P. Rao, Y.V.R.K. Prasad, M. Gupta, Mater. Sci. Eng. A 559, 773–781 (2013)

Y. Xu, J.S. Liu, Y.X. Jiao, Met. Mater. Int. 419, 99 (2019)

M.S. Chen, Y.C. Lin, X.S. Ma, Mater. Sci. Eng. A 556, 260–266 (2012)

H.R. Abedi, A. Zarei Hanzaki, Z. Liu, R. Xin, N. Haghdadi, P.D. Hodgson, Mater. Des. 114, 55–64 (2017)

J.S. Zhang, Y.F. Xia, G.Z. Quan, X. Wang, J. Zhou, J. Alloys Compd. 743, 464–478 (2018)

Y. Xu, C. Chen, X.X. Zhang, H.H. Dai, J.B. Jia, Z.H. Bai, Mater. Charact. 145, 39–52 (2018)

Y. Cai, C.Y. Sun, W. Li, Acta Metall. Sin. 52, 1123–1132 (2016)

J.W. Lee, K.T. Son, T.K. Jung, Y.O. Yoon, S.K. Kim, H.J. Choi, S.K. Hyun, Mater. Sci. Eng. A 673, 648–659 (2016)

G.L. Ji, Q. Li, L. Li, Mater. Sci. Eng. A 586, 197–203 (2013)

Z.P. Wan, S. Yu, L.X. Hu, H. Yu, Mater. Des. 122, 11–20 (2017)

E. Ghasemi, A. Zarei-Hanzaki, E. Farabi, K. Tesař, A. Jäger, M. Rezaee, J. Alloys Compd. 695, 1706–1718 (2017)

M.S. Chen, Y.C. Lin, K.K. Li, Procedia Eng. 207, 2125–2130 (2017)

A. Momeni, S.M. Abbasi, M. Morakabati, H. Badri, X. Wang, Mater. Sci. Eng. A 615, 51–60 (2014)

B. Gong, X.W. Duan, J.S. Liu, J.J. Liu, Vacuum 155, 345–357 (2018)

Z. Zeng, L. Chen, F. Zhu, J. Mater. Sci. Technol. 27, 913–919 (2011)

G.R. Ebrahimi, H. Keshmiri, A.R. Maldad, A. Momeni, J. Mater. Sci. Technol. 28, 467–473 (2012)

E.I. Poliak, J.J. Jonas, Acta Mater. 44, 127–136 (1996)

H. Mirzadeh, A. Najafizadeh, Mater. Des. 31, 1174–1179 (2010)

S.W. Du, S.M. Chen, J.J. Song, Y.T. Li, Metall. Mater. Trans. A 48, 1–11 (2017)

L. Zhang, W.Y. Yang, Z.Q. Sun, J. Univ. Sci. Technol. Beijing 14, 130–135 (2007)

H. Yu, Y.L. Kang, K.L. Wang, J. Fu, Z.B. Wang, D.L. Liu, Mater. Sci. Eng. A 363, 86–92 (2003)

L.X. Kong, P.D. Hodgson, B. Wang, J. Mater. Process Technol. 89–90, 44–50 (1999)

Acknowledgements

This work was financially sponsored by the Fund for Shanxi Key Subjects Construction.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Duan, X.W., Liu, J.J., Gong, B. et al. Experimental Study and Numerical Simulation of Dynamic Recrystallization Behavior of a High-Strength Steel. Met. Mater. Int. 27, 1044–1059 (2021). https://doi.org/10.1007/s12540-019-00433-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00433-w