Abstract

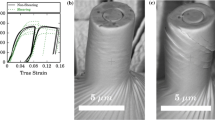

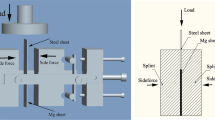

This paper reports the mechanical properties and formability under biaxial stretching in pure tantalum as a function of average grain size. The grain size of pure tantalum was adjusted from submicron to tens of micron using the high-pressure torsion process and subsequent annealing. The stretch formability was evaluated using a miniaturized Erichsen tester. Under uniaxial tension, the mechanical properties of pure tantalum followed the typical strength-ductility trade-off behavior according to the average grain size. Nevertheless, the stretch formability became rather significantly inferior in the coarse-grain tantalum, which was primarily attributed to the poor resistance to strain localization and limited work hardening capacity. This deterioration was supposed to be due to the intensified strain localization with increasing the average grain size, based on the in-grain deformation heterogeneity within individual grains and the surface roughening after the Erichsen test. Consequently, this study suggests that the excellent stretch formability and work hardening capacity under biaxial loading can be achieved at a certain range of the average grain size (8.25–19.3 μm in this work).

Similar content being viewed by others

References

R.W. Buckman Jr., JOM 52, 40 (2000)

W. Köck, P. Paschen, JOM 41, 33 (1989)

A. Nishino, J. Power Sources 60, 137 (1996)

J. Virkki, T. Seppälä, L. Frisk, P. Heino, Microelectron. Reliab. 50, 217 (2010)

H. Matsuno, A. Yokoyama, F. Watari, M. Uo, T. Kawasaki, Biomaterials 22, 1253 (2001)

M. Geetha, A.K. Singh, R. Asokamani, A.K. Gogia, Prog. Mater Sci. 54, 397 (2009)

I.H.G. Livingstone, K. Verolme, C.J. Hayhurst, Int. J. Impact Eng 26, 453 (2001)

J.I. Yoon, J. Jung, S.-H. Joo, T.J. Song, K.-G. Chin, M.H. Seo, S.-J. Kim, S. Lee, H.S. Kim, Mater. Lett. 180, 322 (2016)

J.I. Yoon, H.H. Lee, J. Jung, H.S. Kim, Mater. Sci. Eng. A 735, 295 (2018)

R. Narayanasamy, C.S. Narayanan, Mater. Des. 29, 1467 (2008)

X. Huang, Y. Chino, M. Mabuchi, M. Matsuda, Mater. Sci. Eng. A 611, 152 (2014)

J.W. Park, S.J. Park, K.S. Shin, Met. Mater. Int. 23, 444 (2017)

R. Narayanasamy, R. Ponalagusamy, S. Raghuraman, Mater. Des. 29, 884 (2008)

J.W. Signorelli, M.A. Bertinetti, P.A. Turner, Int. J. Plast 25, 1 (2009)

M. Shakeri, A. Sadough, B.M. Dariani, Proc. Inst. Mech Eng. Part B J. Eng. Manuf. 214, 821 (2000)

A.K. Ghosh, Acta Metall. 25, 1413 (1977)

M. Aghaie, R. Mahmudi, JOM 50, 50 (1998)

D.H. Kang, D.-W. Kim, S. Kim, G.T. Bae, K.H. Kim, N.J. Kim, Scr. Mater. 61, 768 (2009)

Z. Fan, H. Mingzhi, S. Deke, Mater. Sci. Eng. A 122, 211 (1989)

R. Yoda, K. Shibata, T. Morimitsu, D. Terada, N. Tsuji, Scr. Mater. 65, 175 (2011)

H. Liu, Y. Shen, J. Ma, P. Zheng, L. Zhang, J. Mater. Eng. Perform. 25, 3599 (2016)

Y.Z. Tian, L.J. Zhao, N. Park, R. Liu, P. Zhang, Z.J. Zhang, A. Shibata, Z.F. Zhang, N. Tsuji, Acta Mater. 110, 61 (2016)

A.P. Zhilyaev, T.G. Langdon, Prog. Mater Sci. 53, 893 (2008)

R. Pippan, S. Scheriau, A. Hohenwarter, M. Hafok, Mater. Sci. Forum 584, 16 (2008)

N. Maury, N.X. Zhang, Y. Huang, A.P. Zhilyaev, T.G. Langdon, Mater. Sci. Eng. A 638, 174 (2015)

S.N. Mathaudhu, K.T. Hartwig, Mater. Sci. Eng. A 426, 128 (2006)

ISO 20482, Metallic materials—sheet and strip—Erichsen cupping test. http://www.iso.org (2013)

J.I. Yoon, J. Jung, H.H. Lee, H.S. Kim, JOM 70, 912 (2018)

J.W. Bae, J. Moon, M.J. Jang, D. Yim, D. Kim, S. Lee, H.S. Kim, Mater. Sci. Eng. A 703, 324 (2017)

H.Y. Um, E.Y. Yoon, D.J. Lee, C.S. Lee, L.J. Park, S. Lee, H.S. Kim, Scr. Mater. 71, 41 (2014)

H.Y. Um, H.J. Jeong, H.Y. Kim, L.J. Park, S. Lee, H.S. Kim, Scr. Mater. 82, 41 (2014)

M. El, P.H.R. Pereira, Y. Huang, H. Park, H. Choe, T.G. Langdon, J. Gubicza, Mater. Lett. 214, 240 (2018)

D. Colas, E. Finot, S. Flouriot, S. Forest, M. Mazière, T. Paris, Mater. Sci. Eng. A 615, 283 (2014)

O. Saray, G. Purcek, I. Karaman, H.J. Maier, Metall. Mater. Trans. A 44, 4194 (2013)

D.M. Sekban, O. Saray, S.M. Aktarer, G. Purcek, Z.Y. Ma, Mater. Sci. Eng. A 642, 57 (2015)

O. Saray, G. Purcek, I. Karaman, H.J. Maier, Mater. Sci. Eng. A 619, 119 (2014)

S. Ghosh, A.K. Singh, S. Mula, Mater. Des. 100, 47 (2016)

S. Patra, S.M. Hasan, N. Narasaiah, D. Chakrabarti, Mater. Sci. Eng. A 538, 145 (2012)

W. Boas, M.E. Hargreaves, Proc. R. Soc. A 193, 89 (1948)

J. Jiang, T.B. Britton, A.J. Wilkinson, Acta Mater. 61, 7227 (2013)

D. Raabe, M. Sachtleber, H. Weiland, G. Scheele, Z. Zhao, Acta Mater. 51, 1539 (2003)

D.V. Wilson, W.T. Roberts, P.M.B. Rodrigues, Metall. Trans. A 12, 1603 (1981)

Z. Zhao, R. Radovitzky, A. Cuitiño, Acta Mater. 52, 5791 (2004)

M.R. Stoudt, R.E. Ricker, Metall. Mater. Trans. A 33, 2883 (2002)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, H.H., Hwang, K.J., Jung, J. et al. Grain Size Effect on Mechanical Properties Under Biaxial Stretching in Pure Tantalum. Met. Mater. Int. 25, 1448–1456 (2019). https://doi.org/10.1007/s12540-019-00294-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00294-3