Abstract

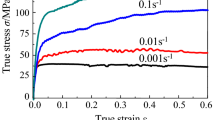

The hot compressive flow behavior of the cast Mg–9.5Zn–2.0Y alloy as a function of strain was analyzed, and the degree of dependence of the parameters (A: material constant, n 2: stress exponent, Q c: activation energy for plastic flow and α: stress multiplier) of the constitutive equation (\(\dot \varepsilon = A{\left[ {\sinh \left( {\alpha \sigma } \right)} \right]^{{n_2}}}\exp \left( {\frac{{ - {Q_c}}}{{RT}}} \right)\)) upon the strain was examined in a systematic manner. This is to explore the possibility of representing the hot compressive deformation behavior of metallic alloys in a simple way by using a reduced number of strain-dependent constitutive parameters. The analysis results for several different cases can be interpreted as follows: (1) Q c can be treated as being strain-independent, which is physically sensible; (2) while only the microstructure changes as a function of strain at low flow stresses, as the flow stress increases, the power-law creep deformation and power-law breakdown mechanisms change; (3) the regime where only A is strain dependent expanded to higher strain rates and lower temperatures as the strain increased, suggesting that the number of the strain-dependent parameters decreases as the initial microstructure is refined by dynamic recrystallization, and the microstructure approaches a steady state.

Similar content being viewed by others

References

O. D. Sherby, R. H. Klundt, and A. K. Miller, Metall. Trans. A 8, 843 (1977).

O. D. Sherby and P. M. Burke, Prog. Mater. Sci. 13, 323 (1968).

C. M. Sellars and W. J. Tegart, Acta Metall. 14, 1136 (1966).

H. Li, X. Wei, J. Ouyang, J. Jiang, and Y. Li, T. Nonferr. Metal. Soc. 23, 3180 (2013).

Y. C. Lin and G. Liu, Mat. Sci. Eng. A 523, 139 (2009).

C. Liao, H. Wu, S. Lee, F. Zhu, H. Liu, and C. Wu, Mat. Sci. Eng. A 565, 1 (2013).

T. Y. Kwak, H. K. Lim, and W. J. Kim, Mat. Sci. Eng. A 648, 146 (2015).

T. Y. Kwak, H. K. Lim, and W. J. Kim, J. Alloy. compd. 632, 417 (2015).

J. W. Zhao, Z. G. Jiang, G. Q. Zu, W. Du, X. Zhang, and L. Z. Jiang, Met. Mater. Int. 22, 474 (2016).

K. S. Choi, J. H. Hwang, K. H. Lee, and K. S. Shin, Korean. J. Met. Mater. 53, 569 (2015).

S. M. Lee, J. W. Lee, H. J. Choi, and S. K. Hyun, Korean. J. Met. Mater. 54, 793 (2016).

N. V. R. Kumar, J. J. Blandin, C. Desrayaud, F. Montheillet, and M. Suéry, Mat. Sci. Eng. A 359, 150 (2003).

J. Cai, F. Li, T. Liu, B. Chen, and M. He, Mater. Design 32, 1144 (2011).

W. Li, H. Li, Z. Wang, and Z. Zheng, Mat. Sci. Eng. A 528, 4098 (2011).

S. Mandal, V. Rakesh, P. V. Sivaprasad, S. Venugopal, and K. V. Kasiviswanathan, Mat. Sci. Eng. A 500, 114 (2009).

H. Y. Li, Y. Liu, X. C. Lu, and X. J. Su, J. Mater. Sci. 47, 5411 (2012).

H. Y. Li, Y. H. Li, D. D. Wei, J. J. Liu, and X. F. Wang, Mat. Sci. Eng. A 530, 367 (2011).

C. Liao, H. Wu, Y. Wu, F. Zhu, and S. Lee, Prog. Nat. Sci. Mater. Int. 24, 253 (2014).

F. A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, J. Mater. Sci. 43, 7165 (2008).

H. Mirzadeh, J. Mag. Alloy. 2, 225 (2014).

H. Mirzadeh, Mech. Mater. 85, 66 (2015).

O. D. Sherby, J. L. Lytton, and J. E. Dorn, Acta Metall. 5, 219 (1957).

K. L. Murty, M. Gold, and A. L. Ruoff, J. Appl. Phys. 41, 4917 (1970).

T. Y. Kwak, H. K. Lim, and W. J. Kim, J. Alloy. compd. 644, 645 (2015).

L.-X. Wang, G. Fang, M. A. Leeflang, J. Duszczyk, and J. Zhou, J. Alloy. compd. 622, 121 (2015).

Z. Cai, F. Chen, F. Ma, and J. Guo, J. Alloy. compd. 670, 55 (2016).

N. Tahreen, D. F. Zhang, F. S. Pan, X. Q. Jiang, C. Li, D. L. Chen, et al. J. Alloy. compd. 644, 814 (2015).

W. X. Wu, L. Jin, J. Dong, and W. Jiang, T. Nonferr. Met. Soc. 22, 1169 (2012).

H. Wu, J. Yang, F. Zhu, and C. Wu, Mat. Sci. Eng. A 574, 17 (2013).

X. Tang, B. Wang, Y. Huo, W. Ma, J. Zhou, H. Ji, et al. Mater. Sci. Eng. A 662, 54 (2016).

H. J. Frost and M. F. Ashby, Deformation-Mechanism Maps, p. 44, Pergamon Press, Oxford, UK (1982).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, W.J., Kwak, T.Y. Constitutive modeling and understanding of the hot compressive deformation of Mg–9.5Zn–2.0Y magnesium alloy with reduced number of strain-dependent constitutive parameters. Met. Mater. Int. 23, 660–672 (2017). https://doi.org/10.1007/s12540-017-6723-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6723-8