Abstract

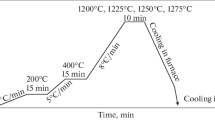

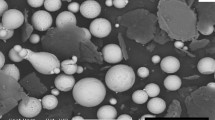

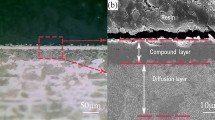

Ni-based composite coatings containing varied contents of tungsten carbides on low carbon steel were fabricated. Effects of sintering temperature and tungsten carbides contents on the surface, interface, microstructure and wear resistance of the coatings were investigated using scanning electron microscopy, energy-dispersive X-ray spectroscopy, X-ray diffraction, Vickers microhardness tester, bulk hardness tester and pin-on-disc tribometer. The results indicated that with appropriate sintering temperature (1230 °C), smooth coating surfaces can be achieved. Favorable interfaces about 200 μm can be got that both the chemical composition and property of the interfacial region showed gradual transitions from the substrates to the coatings. Microstructure of the coatings consists of tungsten carbides and M7C3/M23C6 in the matrix. With excessive sintering temperature, tungsten carbides tend to dissolve. Ni-based coatings containing tungsten carbides showed much higher level of bulk hardness and wear resistance than ISO Fe360A and ASTM 1566 steels. With increasing contents of tungsten carbides from 25% to 40%, bulk hardness of Ni-based coatings gradually increased. Ni-based coating with 35% tungsten carbides performed the best wear resistance.

Similar content being viewed by others

References

H. Wang, W. M. Xia, and Y. S. Jin, Wear 195, 47 (1996).

M. J. Tobar, C. Álvarez, J. M. Amado, G. Rodríguez, and A. Yáñez, Surf. Coat. Tech. 200, 6313 (2006).

S. Zhou, Y. Huang, and X. Zeng, Appl. Surf. Sci. 254, 3110 (2008).

S. Zhou, Y. Huang, X. Zeng, and Q. Hu, Mater. Sci. Eng. A 480, 564 (2008).

S. Zhou, X. Zeng, Q. Hu, and Y. Huang, Appl. Surf. Sci. 255, 1646 (2008).

J. Qu, W. Xiong, D. Ye, Z. Yao, W. Liu, and S. Lin, Int. J. Refract. Met. H. 28, 243 (2010).

E. Taheri-Nassaj and S. H. Mirhosseini, J. Mater. Process. Tech. 142, 422 (2003).

L. Y. Sheng, F. Yang, T. F. Xi, and J. T. Guo, J. Alloy. Compd. 554, 182 (2013).

L.-M. Berger, Int. J. Refract. Met. H. 49, 350 (2015).

S. Chen, J. Liang, C. Liu, K. Sun, and J. Mazumder, Appl. Surf. Sci. 258, 1443 (2011).

Y. Lyu, Y. Sun, and F. Jing, Ceram. Int. 41, 10934 (2015).

N. Serres, F. Hlawka, S. Costil, C. Langlade, and F. Machi, Appl. Surf. Sci. 257, 5132 (2011).

P. Wu, H. M. Du, X. L. Chen, Z. Q. Li, H. L. Bai, and E. Y. Jiang, Wear 257, 142 (2004).

C. Guo, J. Chen, J. Zhou, J. Zhao, L. Wang, Y. Yu, and H. Zhou, Surf. Coat. Tech. 206, 2064 (2012).

C. P. Paul, H. Alemohammad, E. Toyserkani, A. Khajepour, and S. Corbin, Mater. Sci. Eng. A 464, 170 (2007).

G. Y. Liang and T. T. Wong, J. Mater. Eng. Perform. 6, 41 (1997).

P. H. Chong, H. C. Man, and T. M. Yue, Surf. Coat. Tech. 145, 51 (2001).

F. Luo, A. Cockburn, M. Sparkes, R. Lupoi, Z.-J. Chen, W. O’Neill, J.-H. Yao, and R. Liu, Defence Technology 11, 35 (2015).

Y. L. Yan, Y. Zheng, H. J. Yu, H. J. Bu, X. Cheng, and N. W. Zhao, Powder. Metall. Met. C+ 46, 449 (2007).

E. O. Correa, J. N. Santos, and A. N. Klein, Int. J. Refract. Met. H. 28, 572 (2010).

J. Archard and W. Hirst, P. Roy. Soc. Lond. A. Mat. 236, 397 (1956).

Y. Lyu, E. Bergseth, U. Olofsson, A. Lindgren, and M. Höjer, Wear 338-339, 36 (2015).

Y. Lyu, Y. Zhu, and U. Olofsson, Wear 328-329, 277 (2015).

Y. Zhu, Y. Lyu, and U. Olofsson, Wear 324-325, 122 (2015).

U. De Oliveira, V. Ocelík, and J. T. M. De Hosson, Surf. Coat. Tech. 201, 533 (2006).

U. De Oliveira, V. Ocelík, and J. T. M. De Hosson, Surf. Coat. Tech. 201, 6363 (2007).

Q.-Y. Wang, S.-L. Bai, Y.-F. Zhang, and Z.-D. Liu, Appl. Surf. Sci. 308, 285 (2014).

C. Cui, F. Ye, and G. Song, Surf. Coat. Tech. 206, 2388 (2012).

Q. Li, T. C. Lei, and W. Z. Chen, Surf. Coat. Tech. 114, 285 (1999).

X.-M. He, X.-B. Liu, M.-D. Wang, M.-S. Yang, S.-H. Shi, G.-Y. Fu, and S.-F. Chen, Appl. Surf. Sci. 258, 535 (2011).

J. Iwaszko, Surf. Coat. Tech. 201, 3443 (2006).

H.-F. Xuan, Q.-Y. Wang, S.-L. Bai, Z.-D. Liu, H.-G. Sun, and P.-C. Yan, Surf. Coat. Tech. 244, 203 (2014).

C. B. Finch, O. B. Cavin, and P. F. Becher, J. Cryst. Growth. 67, 556 (1984).

H. Liu, C. Wang, X. Zhang, Y. Jiang, C. Cai, and S. Tang, Surf. Coat. Tech. 228, 296 (2013).

Y. Sun, Y. Lyu, A. Jiang, and J. Zhao, J. Mater. Res. 29, 260 (2014).

G. Hu, H. Meng, and J. Liu, Appl. Surf. Sci 317, 378 (2014).

Y. Lv, Y. Sun, J. Zhao, G. Yu, J. Shen, and S. Hu, Mater. Design 39, 303 (2012).

Y. Sun, Y. Lv, L. Wang, J. Shen, X. Jia, and J. Zhao, Oxid. Met. 80, 113 (2012).

Y. F. Sun, Y. Z. Lv, Y. Zhang, J. Y. Zhao, and Y. Wu, Mater. Sci. Tech. Ser. 29, 511 (2013).

S. F. Gnyusov and S. Y. Tarasov, Appl. Surf. Sci. 293, 318 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lyu, Y., Sun, Y. & Yang, Y. Non-vacuum sintering process of WC/W2C reinforced Ni-based coating on steel. Met. Mater. Int. 22, 311–318 (2016). https://doi.org/10.1007/s12540-016-5462-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-5462-6