Abstract

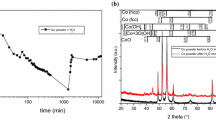

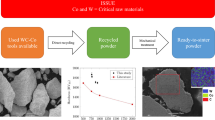

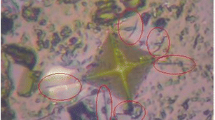

The effects of mechanical milling on the carbothermal reduction of oxidized WC/Co hardmetal scrap with solid carbon were examined. Mixed powders were manufactured by milling the WC/Co hard metal scrap oxide and carbon powder in either a tumbler-ball mill or a planetary-ball mill. The milling type affected the carbothermal reduction of the oxide owing to the differing collision energies (mechanical milling energies) in the mills. The hardmetal scrap oxide powder (WO3, CoWO4) milled at high energy was more greatly reduced and at a lower temperature than that milled at lower mechanical energy. The formation of WC by the carburization reaction with solid carbon reached completion at a lower temperature after higher-energy milling than after lower-energy milling. The WC/Co composite particles synthesized by the combined oxidationmechanical milling-carbothermal reduction process were smaller when the initial powder was milled at higher mechanical energy.

Similar content being viewed by others

References

K. J. A. Brookes, World Directory and Handbook of Hardmetals and Hard Materials, Sixth ed., pp.9–20, International Carbide Data, Hertfordshire (1996).

K. Halada, J. Jap. Soc. Powder & Powder Metall. 57, 87 (2010).

E. Lassner and W. D. Schubert, Tungsten Properties, Chemistry, Technology of the Element, Alloys and Chemical Compounds, pp.377–385, Bloating-Crushing Process Kluwer Academic Plenum Publishers, New York (1999).

C. S. Freemantle, N. Sacks, M. Topic, and C. A. Pineda-Vargas, Int. J. Refrac. Met. Hard Mater. 44, 94 (2014).

E. Altuncu, F. Ustel, A. Turk, S. Ozturk, and G. Erdogan, Mater. & Technol. 47, 115 (2013).

E. Lassner, Int. J. Refrac. Met. Hard Mater. 13, 35 (1995).

T. Ishida, T. Itakura, H. Moriguchi, and A. Ikegaya, SEI Technical Review 75, 38 (2012).

J. C. Lee, E. Y. Kim, J. H. Kim, W. Kim, B. S. Kim, and B. D. Pandey, Int. J. Refrac. Met. Hard Mater. 29, 365 (2011).

A. Sampath and T. S. Sudarshan, Powder Metall. 45, 21 (2002).

J. C. Lin, J. Y. Lin and S. L. Lee, U. S. Patent, No.5384016 (1995).

A. M. Human and H. E. Exner, Mater. Sci. Eng. A 209, 180 (1996).

S. Wongsisa, P. Srichandr, and N. Poolthong, Mater. Trans. 56, 70 (2015).

G. G. Lee and G. H. Ha, J. Korean Powder Metall. Inst. 12, 112 (2005).

R. Joost, J. Pirso, M. Viljus, S. Letunovits, and K. Juhani, Estonian J. Eng. 18, 127 (2012).

W. G. Jung, J. Ind. Eng. Chem. 20, 2384 (2014).

K. J. A. Brookes, World Directory and Handbook of Hardmetals and Hard Materials, Sixth ed., pp.95–102, International Carbide Data, Hertfordshire (1996).

H. J. Fecht, E. Hellstern, Z. Fu, and W. L. Johnson, Metall. Trans. A 21A, 1990 (1990).

M. A. Xueming and J. I. Gang, J. Alloy. Compd. 245, L30 (1996).

M. H. Enayati, G. R. Aryanpour, and A. Ebnonnasir, Int. J. Refrac. Met. Hard Mater. 27, 159 (2009).

L. L. Shaw, Adv. Eng. Mater. 2, 721 (2000).

W. Liu, X. Song, J. Zhang, G. Zhang, and X. Liu, Int. J. Refrac. Met. Hard Mater. 27, 115 (2009).

Z. G. Ban and L. L. Shaw, J. Mater. Sci. 37, 3397 (2002).

Y. Zhang and L. L. Shaw, J. Mater. Sci. 46, 6323 (2011).

G. G. Lee, G. H. Ha, and B. K. Kim, J. Kor. Inst. Metal. & Mater. 37, 1233 (1999).

Z. Zhang, S. Wahlberg, M. Wang, and M. Muhammed, Nanostruct. Mater. 12, 163 (1999).

T. Ryu, H. Y. Sohn, G. Han, Y. Kim, K. S. Hwang, M. Mena, and Z. Z. Fang, Metall. Mater. Trans. B 39, 1 (2008).

J. Hojo, T. Oku, and A. Kato, J. Less-Common Metal 59, 85 (1978).

B. D. Cullity, Elements of X-ray Diffraction, Second ed., pp.81–145, Addison-Wesley Publishing Company Inc., London (1978).

G. K. Williamson and W. H. Hall, Acta Metall. 1, 22 (1953).

K. Venkateswarlu, A. C. Bose, and N. Rameshbabu, Physica B 405, 4256 (2010).

ASM International Committee, ASM Handbook Vol. 7 Powder Metal Technologies and Application, pp.53–66, ASM International, New York (1998).

J. Schilz, Mater. Trans. JIM 39, 1152 (1998).

N. Burgio, A. Iasonna, M. Magini, S. Martelli, and F. Padella, Il Nuovo Cimento 13, 459 (1991).

H. K. Khoa, S. W. Bae, S. W. Bae, B. W. Kim, and J. S. Kim, J. Korean. Powder. Metall. Inst. 21, 155 (2014).

R. Abbaschian, L. Abbaschian, and R. E. Reed-Hill, Physical Metallurgy Principles, Fourth ed., pp.348–407, Cengage Learning, New York (2010).

Z. Sadighi, A. Ataie, and M. R. Barati, Met. Mater. Int. 20, 77 (2014).

S. M. Kwon, N. R. Park, J. W. Shin, S. H. Oh, B. S. Kim, and I. J. Shon, Korean J. Met. Mater. 53, 555 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, GG., Ha, GH. Effects of mechanical milling on the carbothermal reduction of oxide of WC/Co hardmetal scrap. Met. Mater. Int. 22, 260–266 (2016). https://doi.org/10.1007/s12540-016-5409-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-5409-y