Abstract

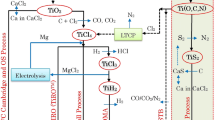

Ti-based solid-solution carbonitrides (Ti,Al,V)(CN) and (Ti,Al,Mo,V)(CN), were synthesized successfully using Ti-6Al-4V (Ti-64) and Ti-8Al-1Mo-1V (Ti-811) alloy scraps via hydrogenation-dehydrogenation and highenergy milling processes. A single phase of (Ti,Al,V)(CN) could be readily synthesized by the high-energy milling of Ti-64 alloy with graphite in a nitrogen atmosphere regardless of the carbon content. On the other hand, for the Ti-811 alloy, metallic Mo and various Mo-less carbides, in this case Ti2AlC, Ti3AlC2, and Ti3AlC, were also formed in addition to (Ti,Al,Mo,V)(CN) due to the low nitrogen affinity of Mo. The solid-solution carbonitrides consolidated by spark plasma sintering revealed excellent mechanical properties (HV: 19.1-20.6 GPa, KIC: 5.2-6.4 MPa·m1/2) due to the alloying effect of Al, Mo, and V in Ti(CN). These values are superior to those of typical Ti(CN)–based ceramic composites (HV: 16-20 GPa, KIC: 3.2-5.5 MPa·m1/2). We believe that the suggested method would be a valuable option for the production of Ti-based solid-solution carbonitrides with decent mechanical properties economically.

Similar content being viewed by others

References

P. Ettmayer, Annu. Rev. Mater. Sci. 19, 145 (1989).

S. Kang, Comprehensive Hard Materials (eds. D. Mari, L. Llanes, and C. E. Nebel), pp. 139–181, Elsevier Ltd., Boston (2014).

Y. Choi, Met. Mater. Int. 20, 531 (2014).

J. Jung and S. Kang, J. Am. Ceram. Soc. 90, 2178 (2007).

S. Kim, K.-H. Min, and S. Kang, J. Am. Ceram. Soc. 86, 1761 (2003).

J. Jung and S. Kang, Acta Mater. 52, 1379 (2004).

S. Zhou, W. Zhao, and W. Xiong, Int. J. Refract. Met. Hard Mater. 27, 26 (2009).

W. Wan, J. Xiong, Z. Guo, H. Du, and L. Tang, Int. J. Refract. Met. Hard Mater. 45, 86 (2014).

Y. Peng, H. Miao, and Z. Peng, Int. J. Refract. Met. Hard Mater. 39, 78 (2013).

P. H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens, Prog. Mater. Sci. 51, 1032 (2006).

A. Horling, L. Hultman, M. Oden, J. Sjolen, and L. Karlsson, Surf. Coat. Tech. 191, 384 (2005).

G. S. Fox-Rabinovich, J. L. Endrino, B. D. Beake, A. I. Kovalev, S. C. Veldhuis, L. Ning, F. Fontaine, and A. Gray, Surf. Coat. Tech. 201, 3524 (2006).

E. B. Clark and B. Roebuck, Int. J. Refract. Met. Hard Mater. 11, 23 (1992).

S. Park and S. Kang, Scripta Mater. 52, 129 (2005).

J. Jung and S. Kang, Script Mater. 56, 561 (2007).

G. Y. Yoo, C. H. Park, J.-K. Hong, S.-E. Kim, N. H. Kang, and J.-T. Yeom, Korean J. Met. Mater. 51, 307 (2013).

T. Moskalewicz, S. Zimowski, B. Wendler, P. Nolbrzak, and A. Czyrska-Filemonowicz, Met. Mater. Int. 20, 269 (2014).

J. M. Oh, K. M. Roh, B. K. Lee, C. Y. Suh, W. Kim, and H. Kwon, J. Alloys Compd. 593, 61 (2014).

D. K. Shetty, I. G. Wright, P. N. Mincer, and A. H. Clauer, J. Mater. Sci. 20, 1873 (1985).

I. Barin, Thermochemical Data of Pure Substances, pp.42–1628, VCH Verlagsgesellschaft mbH, Weinheim (1989).

H. Jehn and P. Ettmayer, J. Less-common Met. 58, 85 (1978).

D. S. Park and Y. D. Lee, J. Am. Ceram. Soc. 82, 3150 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, SA., Kwon, H., Roh, KM. et al. Ti-based solid solution carbonitrides prepared from Ti-alloy scraps via a hydrogenation-dehydrogenation process and high-energy milling. Met. Mater. Int. 21, 923–928 (2015). https://doi.org/10.1007/s12540-015-5050-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-5050-1