Abstract

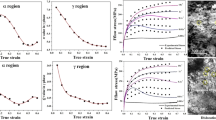

The aim of this work is to develop a constitutive model that can predict the flow behavior of pure Ti with different interstitial concentrations and grain sizes. To build a database required for identifying material constants, three different grades of Ti were subjected to tensile tests at temperatures of 223, 300, 473, 673 or 773 K and at a fixed strain rate of 10−3 s−1. In the modeling procedure, the mechanical threshold stress model was further modified to capture both the hardening effects attributed to the changes in equivalent oxygen concentration (O eq ) and the softening effect caused by deformation heating at high strain rates. The developed model can reasonably predict the flow behavior of pure Ti having different O eq (0.14–0.32 wt%), and grain size (14.5–90 μm) over a temperature range of 135 to 673 K, and a strain rate range of 2×10−4 to 1400 s−1.

Similar content being viewed by others

References

H. Conrad, M. Doner and B. de Meester, Proc. The 2nd International Conference on Titanium Science and Technology, p. 969 (1973).

S. Nemat-Nasser, W. G. Guo, and J. Y. Cheng, Acta Mater. 47, 3705 (1999).

C.-S. Oh and C.-S. Han, Korean J. Met. Mater. 51, 557 (2013).

S. J. Kim, K. Choi, and S.-Y. Choi, Korean J. Met. Mater. 51, 701 (2013).

A. A. Salem, S. R. Kalidindi, and R. D. Doherty, Acta Mater. 51, 4225 (2003).

K. Ahn, H. Huh, and J. Yoon, Met. Mater. Int. 19, 758 (2013).

S. Nemat-Nasser and J. B. Isaacs, Acta Mater. 45, 907 (1997).

S. Nemat-Nasser and R. Kapoor, Int. J. Plasticity. 17, 1351 (2001).

W.-G. Guo and S. Nemat-Nasser, Mechanics of Materials 38, 1090 (2006).

Q. Li, Y. B. Xu, and M. N. Bassim, J. Mater. Proc. Technol. 155–156, 1889 (2004).

F. J. Zerilli and R. W. Armstrong, J. Appl. Phys. 61, 1816 (1987).

A. A. Salem, S. R. Kalidindi, and S. L. Semiatin, Acta Mater. 53, 3495 (2005).

S. R. Kalidindi, J. Mech. Phys. Solid. 46, 267 (1998).

P. S. Follansbee and U. F. Kocks, Acta Metall. 36, 81 (1988).

C. H. Park, S.-G. Hong, and C. S. Lee, Mater. Sci. Eng. A 528, 1154 (2011).

B. de Meester,_M. Doner, and H. Conrad, Metall. Trans. 6A, 65 (1975).

S. Nemat-Nasser, W. G. Guo, V. F. Nesterenko, S. S. Indrakanti, and Y. B. Gu, Mech. Mater. 33, 425 (2001).

G. R. Johnson and W. H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures, pp. 541–547 (1983).

H. Conrad, Effect of Interstitial Solutes on the Strength and Ductility of Titanium, Pergamon Press, Oxford, New York (1981).

G. E. Dieter, Mechanical Metallurgy, pp.310–314, McGraw-Hill, London (1988).

R. C. Picu and A. Majorell, Materials Science and Engineering A 326, 306 (2002).

W. Smith and J. Hashemi, Foundations of Materials Science and Engineering (4th ed.), p. 242 (2006).

Y. B. Chun, S. H. Yu, S. L. Semiatin, and S. K. Hwang, Materials Science and Engineering. A 398, 209 (2005).

V. A. Moskalenko and A. R. Smirnov, Mater. Sci. Eng. A 246, 282 (1998).

W. Huang, X. Zan, X. Nie, M. Gong, Y. Wang, and Y. Xia, Mater. Sci. Eng. A 443, 33 (2007).

C. Park, Y. Son, and C. Lee, J. Mater. Sci. 47, 3115 (2012).

R. Kapoor and S. Nemat-Nasser, Mech. Mater. 27, 1 (1998).

D. R. Chichili, K. T. Ramesh, and K. J. Hemker, Acta Mater. 46, 1025 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Won, J.W., Park, C.H., Lee, T. et al. Integrated constitutive model for flow behavior of pure Titanium considering interstitial solute concentration. Met. Mater. Int. 20, 1017–1025 (2014). https://doi.org/10.1007/s12540-014-6004-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-014-6004-8