Abstract

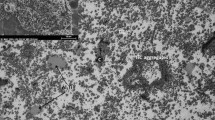

In situ Al/TiC composites with a homogeneous distribution of TiC reinforcements were prepared by adding a reactant mixture of Al-Ti-C to an Al melt. A certain amount of CuO addition facilitates a combustion reaction of the Al-Ti-C system and thereby enables the formation of in situ TiC at a reasonably low temperature range of 750–920 °C. Synthesised TiC particles with sizes of 1–2 μm are present in the Al matrix along with Al3Ti. Besides the CuO addition, the melt temperature plays a significant role in the final microstructure of the composites. Increase in the melt temperature up to 920 °C with CuO provides more external heat input and initiates the combustion reaction within a few seconds. Pellet microstructure evidently shows that the polygonal Al3Ti originates from the unreacted layer of which the distance is significantly shortens by increasing the melt temperature. The suppression of the Al3Ti formation is the most likely to occur at 920 °C, with producing a large volume fraction of TiC in situ synthesised.

Similar content being viewed by others

References

P. Sahoo and M. J. Koczak, Mater. Sci. Eng. A 131, 69 (1991).

I. Gotman, M. J. Koczak, and E. Shtessel, Mater. Sci. Eng. A 187, 189 (1994).

H. Nakata, T. Choh, and N. Kanetake, J. Mater. Sci. 30, 1719 (1995).

X. C. Tong and H. S. Fang, Metall. Mater. Trans. A 29, 893 (1998).

C. Selcuk and A. R. Kennedy, Mater. Lett. 60, 3364 (2006).

T. Nukami and M. C. Flemings, Metall. Mater. Trans. A 26, 1877 (1995).

B. Yang, G. Chen, and J. Zhang, Mater. Des. 22, 645 (2001).

M. K. Premkumar and M. G. Chu, Mater. Sci. Eng. A 202, 172 (1995).

W. H. Jiang, G. H. Song, X. L. Han, C. L. He, and H. C. Ru, Mater. Lett. 32, 63 (1997).

P. Li, E. G. Kandalova, V. I. Nikitin, A. G. Makarenko, A. R. Luts, and Y. Zhang, Scripta Mater. 49, 699 (2003).

P. Li, E. G. Kandalova, and V. I. Nikitin, Mater. Lett. 59, 2545 (2005).

M. S. Song, M. X. Zhang, S. G. Zhang, B. Huang, and J. G. Li, Mater. Sci. Eng. A 473, 166 (2008).

J. J. Moore and H. J. Feng, Prog. Mater. Sci. 39, 243 (1995).

P. Li, E. G. Kandalova, V. I. Nikitin, A. R. Luts, A. G. Makarenko, and Y. Zhang, Mater. Lett. 57, 3694 (2003).

P. Li, E. G. Kandalova, A. G. Makarenko, V. I. Nikitin, Y. Zhang, and A. R. Luts, Mater. Lett. 58, 1861 (2004).

Z.-J. Huang, B. Yang, H. Cui, and J.-S. Zhang, Mater. Sci. Eng. A 351, 15 (2003).

J. M. Lee, S. H. Kim, Y. H. Cho, J. W. Kim, and J. C. Lee, Korean J. Met. Mater. 49, 1001 (2011).

H. J. Kim, J. M. Lee, Y. H. Cho, J. J. Kim, S. H. Kim, and J. C. Lee, Korean J. Met. Mater. 50, 677 (2012).

A. R. Kennedy, D. P. Weston, M. I. Jones, and C. Enel, Scripta Mater. 42, 1187 (2000).

G. Xiao, Q. Fan, M. Gu, and Z. Jin, Mater. Sci. Eng. A 425, 318 (2006).

E. Zhang, S. Zeng, B. Yang, Q. Li, and M. Ma, Metall. Trans. A 30, 1147 (1999).

M. S. Song, B. Huang, M. X. Zhang, and J. G. Li, Int. J. Refract. Met. Hard Mater. 27, 584 (2009).

G. Chen, G. Sun, and Z. Zhu, Mater. Sci. Eng. A 251, 226 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cho, YH., Lee, JM., Kim, HJ. et al. Feasible process for producing in situ Al/TiC composites by combustion reaction in an Al melt. Met. Mater. Int. 19, 1109–1116 (2013). https://doi.org/10.1007/s12540-013-5028-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5028-9