Abstract

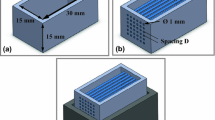

Layered composite materials significantly improved the mechanical process of fracturing, which means better fracture strength, while preserving surface properties such as hardness, resistance to wear and resistance to high temperatures. The properties are significantly influenced by the interphase mass transfer at the surface matrix-fiber reinforcement. We developed a mathematical model to determine the molar flux at the interface in stationary and in a nonstationary regime. The technological parameters are: hydraulic pressure, reinforced material, alloy type, fiber diameter, mass ratio between the reinforcement and the composite masses and mould preheating temperature. A mould patented in Romania was mounted on a hydraulic press to obtain the samples. We studied the material structure, matrix and fiber element distribution, metallic matrix element distribution and matrix and fiber element content variation. The results recorded revealed a 75% to 120% increase of the fracture strength, which means an improvement of the mechanical process of fracturing. We concluded that the reinforcement material, mass ratio and fiber diameter have a significant influences on the fracture strength.

Similar content being viewed by others

References

A. Mortensen and Llorca, J. Metal Matrix Composites 40, 15.1 (2010).

V. V. Skorokhod, Powder Metallurgy and Metal Ceramics 42, 35 (2003).

G. Neagu and Fl. Ştefãnescu, Metalurgia Int. 15, 24 (2007).

T. Altinbalik, Int. J. Modern Manufacturing Technologies 3, 1 (2011).

I. Carcea, Materiale Compozite, p. 38, Politehnium, Romania (2008).

S. G. Simranpreet and M. Kaplas, Materials and Manufacturing Processes 24, 12 (2009).

M. Kalantar, B. M. Moshtaghioun, and A. Monshi, Mater. Eng. Perform. 19, 2 (2010).

D. Nedelcu, P. Cobzaru, P. R. Scurtu, and R. Chelariu, Die for Producing Samples Made of Metal Matrix Composite Material by Liquid Forging, Romanian patent, OSIM, No. RO126022-A2 (2011).

D. Nedelcu and O. Pruteanu, Aspecteale Formarii Canelurilor Exterioare Prin Deformare Plastica la Rece Utilizand Metoda Taguchi, pp.243–257, Tehnica-Info, Moldova (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nedelcu, D., Carcea, I. Technology for obtaining samples of layered composite materials with metallic matrix. Met. Mater. Int. 19, 105–112 (2013). https://doi.org/10.1007/s12540-013-1017-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-1017-2