Abstract

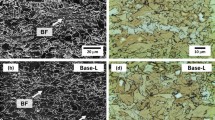

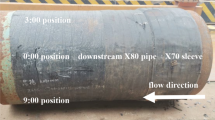

In the present study, spiral piping was conducted on API X80 linepipe steel, and the outer and inner wall pipe yield strengths were measured. A low-cycle fatigue test was conducted on a leveled X80 steel sheet to simulate piping and flattening processes, and the strain hardening and Bauschinger effects, induced from different strain histories, were evaluated and combined using Swift’s equation and the Bauschinger stress parameter, respectively. By analyzing the stress-strain curves obtained from the low-cycle fatigue test, the yield strengths of the outer and inner walls were estimated to be 592 MPa and 492 MPa, respectively, which are lower by 20–80 MPa than that of the actual pipe used. Possible reasons for measured and estimated yield strength differences could be the simulation determining procedure of the pre-strain and Bauschinger stress parameters, preposition of same strain hardening behavior depending on strain history, and pre-strain differences depending on thickness location in the steel sheet during piping.

Similar content being viewed by others

References

R. W. K. Honeycombe, Scand. J. Metall. 8, 21 (1956).

H. Watanabe, Y. E. Smith, and R. D. Pehlke, The Hot Deformation of Austenite (ed. J. B. Balance), p. 140, TMSAIME, New York (1997).

Specification for High-Test Linepipe, Standard 5XL, American Petroleum Institute, API (1996).

Material Specification, Specification No. 2950-6-6, Canadian Arctic Gas Pipeline Limited (1973).

G. E. Dieter, Mechanical Metallurgy, 3 rd ed., p. 236, McGraw-Hill, New York (1979).

R. Sowerby, Y. Tomita, and D. K. Uko, Mater. Sci. Eng. 41, 43 (1979).

T. Taira, T. Osuka, and Y. Ishida, Proc. 15 th Mechanical Working and Steel Processing Conf., p. 33, Pittsburgh (1977).

G. Tither and M. Lavite, J. Met. 27, 15 (1975).

K. J. Pascoe, J. Strain Analysis 6, 167 (1971).

C. D. Singh and V. Ramaswamy, Steel India 6, 89 (1983).

A. Goel, R. K. Ray, and G. S. Murty, Scripta Metall. 17, 375 (1983).

L. Zhonghua and G. Haicheng, Metall. Trans. A21, 717 (1990).

N. Ibrahim and J. D. Embury, Mater. Sci. Eng. A 19, 147 (1975).

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi, Thermomechanical Processing of High-strength Low-alloy Steels, p. 80, Butterworth and Co., Ltd. (1988).

J. Takamura and S. Mizoguchi, Proc. 6 th Int. Iron Steel Congr., p. 591, ISIJ, Japan (1990).

B. Hwang, T. Lee, and S. Kim, Met. Mater. Int. 16, 905 (2010).

D. Wen, Met. Mater. Int. 16, 13 (2010).

ASTM Standard E8m-09, Standard Test Methods for Tension Testing of Metallic Materials, ASTM (2009).

ASTM Standard E606-92, Standard Practice for Strain-Controlled Fatigue Testing, ASTM (1998).

K. Nakajima, W. Mizutani, T. Kikuma, and H. Matumoto, Trans. ISIJ 15, 1 (1975).

K. J. Park and Y. R. Jeo, J. Kor. Inst. Met. Mater. 36, 1777 (1998).

Y. Tomota, M. Umemoto, N. Komatsubara, A. Hiramatsu, N. Nakajima, A. Moriya, T. Watanabe, S. Nanba, G. Anan, K. Kunishige, Y. Higo, and M. Miyahara, ISIJ Int. 32, 343 (1992).

N. S. Mishra, S. Mishra, and V. Ramaswamy, Metall. Mater. Trans. A 20, 2819 (1989).

J. H. Hollomon, Trans. AIME 162, 268 (1945).

H. W. Swift, J. Mech. Phys. Solids 1, 1 (1952).

S. K. Kim, Y. M. Kim, Y. J. Lim, and N. J. Kim, Proc. 15 th Conf. on Mechanical Behaviors of Mater., p.177, Seoul, Korea (2001).

A. Abel and H. Muir, Phil. Mag. 26, 489 (1972).

T. Araki, Atlas for Bainitic Microstructures, p.1, ISIJ, Tokyo, Japan (1992).

G. Krauss and S. W. Thompson, ISIJ 35, 937 (1995).

Y. M. Kim, S. K. Kim, Y. J. Lim, and N. J. Kim, ISIJ Int. 42, 1571 (2002).

I. Choi, Y. Park, D. Son, S. Kim, and M. Moon, Met. Mater. Int. 16, 27 (2010).

Z. Tang and W. Strumpf, Mater. Charact. 59, 717 (2008).

N. Ma, T. Park, D. Kim, C. Kim, and K. Chung, Met. Mater. Int. 16, 427 (2010).

S. J. Kim, C. G. Lee, T. H. Lee, and C. S. Oh, Scripta Mater. 48, 539 (2003).

M. Honjo and Y. Saito, ISIJ Int. 40, 914 (2000).

C. W. Choi, H. J. Koh, and S. Lee, Metall. Mater. Trans. A 31, 2669 (2000).

J. S. Park, D. W. Kim, and Y. W. Chang, Trans. Mater. Process. 15, 118 (2006).

Y. M. Kim, S. K. Kim, and N. J. Kim, Mater. Sci. Forum 475–479, 282 (2005).

H. K. Sung, S. Y. Shin, B. Hwang, C. G. Lee, N. J. Kim, and S. Lee, Korean J. Met. Mater. 48, 798 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sohn, S.S., Han, S.Y., Shin, S.Y. et al. Analysis and estimation of yield strength of API X80 linepipe steel pipe by low-cycle fatigue tests. Met. Mater. Int. 18, 597–606 (2012). https://doi.org/10.1007/s12540-012-4005-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-012-4005-z