Abstract

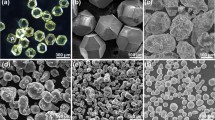

We have successfully fabricated highly densified aluminum (Al)-diamond composite materials by a simple hot press method. The thermal conductivity of the Al-diamond composite materials was measured. These materials had different types, sizes and fractions of diamond. These obtained values were discussed based on theoretically calculated values. The thermal conductivity of the composite materials, measured by Laser-Flash method, was found to have slightly increased compared to that of pure bulk Al. The obtained microstructures of the composite materials showed a lot of cleavage existing in the interface between the Al matrix and the diamond particles, which led to the low increment of the thermal conductivity. Moreover, Al-diamond bulk materials with different sintering temperatures in solid state, liquid phase, and transient region between solid and liquid of Al, have been synthesized.

Similar content being viewed by others

References

W. B. Johnson and B. Sonuparlak, J. Mater. Res. 5, 1169 (1993).

S. Elomari, R. Boukhili, C. S. Marchi, A. Mortensen, and D. J. Lloyd, J. Mater. Sci. 32, 2131 (1997).

V. V. Rao, M. V. K. Murthy, and J. Nagaraju, Comp. Sci. Technol. 64, 2459 (2004).

S. Akbulut, Y. Ocak, K. Keslioglu, and N. Marasli, J. Phy. Chem. Sol. 70, 72 (2009).

M. Battabyal, O. Beffort, S. Kleiner, S. Vaucher, and L. Rohr, Dia. Rel. Mater. 17, 1438 (2008).

P. M. Geffroy, T. Charitier, and J. F. Silvain, Adv. Eng. Mater. 7, 547 (2007).

P. M. Geffroy, T. Charitier, and J. F. Silvain, J. Eur. Ceram. Soc. 27, 291 (2007).

P. W. Ruch, O. Beffort, S. Kleiner, L. Weber, and P. J. Uggowitzer, Comp. Sci. Technol. 66, 2677 (2006).

F. A. Khalid, O. Beffort, U. E. Klotz, B. A. Keller, and P. Gasser, Dia. Rel. Mater. 13, 393 (2004).

S. A. Suilik, M. Oshima, T. Tetsui, and K. Hasezaki, Vacuum 82, 1325 (2008).

T. Schubert, B. Trindade, T. Weibgarber, and B. Kieback, Mater. Sci. Eng. A 475, 39 (2008).

Y. Yamamoto, T. Imai, K. Tanabe, T. Tsuno, Y. Kumazawa, and N. Fujimori, Dia. Rel. Mater. 6, 1057 (1997).

K. Yoshida and H. Morigami, Microelectron. Reli. 44, 303 (2004).

P. M. Geffroy, T. Charitier, and J. F. Silvain, Adv. Eng. Mater. 4, 400 (2008).

O. Beffort, F. A. Khalid, L. Weber, P. Ruch, U. E. Klotz, S. Meier, S Kleiner, Dia. Rea. Mater. 15, 1250 (2006).

K. Chihiro, JP Patent, JP2000303126 (2000).

R. M. German, Sintering Theory and Practice, John Wiley & Sons, New York (1996).

M. N. Rahaman, Ceramic Processing and Sintering, Marcel Dekker, New York (1995).

O. Sudre and F. F. Lange, J. Am. Ceram. Soc. 75, 519 (1992).

J. Besson, Mech. Mater. 19, 103 (1995).

T. Laha, S. Kuchibhatla, S. Seal, W. Li, and A. Agarwal, Acta Mater. 55, 1059 (2007).

H. Kwon, M. Estili, K. Takagi, T. Miyazaki, and A. Kawasaki, Carbon 47, 570 (2009).

M. Kubota, J. Alloy. Compd. 434, 294 (2007).

M. Zadra, F. Casari, L. Girardini, and A. Molinari, Powder Metall. 50, 40 (2007).

G. Xie, O. Ohashi, K. Chiba, N. Yamaguchi, M. Song, K. Furuya, and T. Noda, Mater. Sci. Eng. A 359, 384 (2003).

M. Omori, Mater. Sci. Eng. A 287, 183 (2000).

H. Kwon, D. Park, Y. Park, J.F. Silvain, A. Kawasaki, and Y. Park, Met. Mater. Int. 16, 71 (2010).

L. Ci, Z. Ryu, N.Y. Jin-Phillipp, and M. Ruhle, Acta mater. 54, 5367 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, H., Leparoux, M., Heintz, JM. et al. Fabrication of single crystalline diamond reinforced aluminum matrix composite by powder metallurgy route. Met. Mater. Int. 17, 755–763 (2011). https://doi.org/10.1007/s12540-011-1010-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-011-1010-6