Abstract

This paper addresses technological dynamics revealed through raw material analyses of Late Hallstatt (seventh–fifth centuries BCE) ceramics from the famous Heuneburg site (Herbertingen-Hundersingen, SW Germany). The study combines, for the first time, separate sets of thin-sections produced over the last 50 years in order to provide a comprehensive and consolidated characterisation of technological changes in ceramic production taking place at the site during the Hallstatt phases D1 to D3. It provides significant new insights into the relation between raw material procurement and preparation, on the one hand, and changes in ceramic typology and production methods, on the other hand (i.e. the introduction of the potter’s wheel). The results reveal a shift from a broad spectrum of fabrics tempered with grog, sand or crushed calcite in phase Hallstatt D1, to the increasing use of non-calcareous, grog or sand-tempered fabrics. The new wheel-turned pottery (appearing from phase Hallstatt D3) is exclusively produced using a non-calcareous clay, often tempered with fine sand, indicating a specialisation in raw material selection alongside the introduction of novel shaping techniques. Evidence of continuity between the fabrics used in phase Hallstatt D1 and the new wheel-turned pottery suggests craft specialists drew upon established technological knowledge to integrate the potter’s wheel. The adoption of the potter’s wheel was likely also stimulated by the increased demand for new vessels to accommodate the consumption of fermented drinks such as grape wine, fruit wine or beer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Heuneburg is one of the earliest urban centres north of the Alps, representing a key site for the study of the Late Hallstatt period (Hallstatt D, ca. 620–450 BCE) in Central Europe (Fernández-Götz 2018; Fernández-Götz and Krausse 2013). Extensive excavations at the site and its surroundings, commencing in the nineteenth century and continuing until today, have brought to light evidence for specialised production, social inequalities, monumental architecture, planned settlement layout and contacts to the Greek and Etruscan worlds during the Hallstatt D period (Kimmig 1983; Krausse et al. 2015). At the height of its prosperity around the mid-sixth century BCE, the Heuneburg agglomeration extended over an area of around 100 hectares, with an estimated population of ca. 5000 inhabitants (Krausse et al. 2019) (Fig. 1).

Recreation of the Heuneburg towards the end of Hallstatt D1: Hilltop plateau with Mediterranean-inspired mudbrick wall, lower town and part of the outer settlement (after Krausse et al. 2016; design: Faber Courtial

Ceramics are an important class of archaeological information to address questions surrounding trajectories towards specialisation and novel consumption practices in early urban societies. In Iron Age Central Europe and particularly among the so-called Fürstensitze or ‘princely seats’ (Krausse et al. 2016), ceramics are a key marker of such processes, as well as of increasing connectivity with the Mediterranean world. Such interactions are visible in the increasing presence of imported ceramics from settlements south of the Alps, as well as the changes in the style and technology of locally produced pottery. An important technological change taking place is reflected by the increasing use of the potter’s wheels for the production of ceramics, which often have distinctive grooved decorations (referred to in the literature as geriefte Drehscheibenkeramik, cf. Dehn 1963; Lang 1974; Hopert 1996). Wheel-made ceramics start appearing across southern Germany, Switzerland and central France from approximately the second half of the sixth century BCE, becoming ubiquitous by the end of the Late Hallstatt period and the Early La Tène period in the fifth century BCE (Balzer 2009; Augier et al. 2011; Tappert 2012; Kern et al. 2012).

This paper addresses how such technological changes in ceramic production took effect at the Heuneburg, utilising mineralogical and technological observations from sequences of ceramic thin-sections made over the last 50 years. Petrographic analyses can provide significant insights into diachronic changes in production strategies, and in particular the initial ‘steps’ in the chaîne operatoire (Leroi-Gourhan 1964; Dobres 1999): clay provenance and preparation. Such technological habits have been shown to encompass meaningful variation, significant for addressing the mechanisms along which traditional material knowledge is transmitted to future generations (Gosselain 1992; Wallaert-Pêtre 2001). Thus, by characterising raw material use alongside the spread of the potter’s wheel, which marks a fundamentally different technology from shaping pottery by hand, this study addresses the transmission processes underpinning the adoption of this ‘discontinuous’ innovation. In this sense, the paper considers how this technology formed part of broader socio-economic changes, apparent in settlement layout, consumption practices and material culture styles (Fig. 2).

Fürstensitze north of the Alps and selected sites in Mediterranean Europe (after Fernández-Götz and Ralston 2017)

Geological characteristics of the Heuneburg and its surroundings

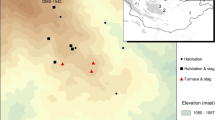

The Heuneburg is located on the northern bank of the Danube River in Southwest Germany (48°04′41″lat, 09°24′43″lon). The Upper Danube region, in which the site is situated, is shaped by Jurassic limestone and marl and tertiary moraines (Dongus 1977; German 1989; Geyer et al. 2011). Moraine loam was selected for the production of mudbricks used in the Mediterranean-inspired mudbrick wall of phase Hallstatt D1 (Gersbach 1995, 35). The site and its immediate surroundings are situated upon sedimentary deposits like gravel, sand, silt and conglomerate. Immediately northwest of the site we find heterogeneous deposits of slate, sandstone and limestone with evaporites and marl. The nearest sources of metamorphic rocks are represented by a band of gneiss intrusions within this sedimentary landscape northwest of the site (Fig. 3).

Ceramic production at the Heuneburg: technology and style

The Heuneburg emerged as a centre for ceramic production during the Early Iron Age. The chronology considered in this article (spanning phases Hallstatt D1, ca. 620–540/530 BCE; D2, 540/530–500 BCE; D3, 500–450 BCE) marks a period of significant changes in ceramic production, beginning with the centralised production of hand-made fine ware to the introduction of imported ceramics from the Mediterranean region alongside the local production of wheel-made ceramics (Fig. 4).

Early Iron Age ceramic production in southwest Germany is marked by three highly decorative typological groups: (1) Alb-Hegau ware, (2) white ground red and grey painted ware (Weißgrundig-rot-graubemalte Keramik) and (3) red-polished pottery with black painted decoration (Dämmer 1978; Stegmaier 2021). Alb-Hegau ware, which first appears between ca. 800 and 620 BCE, has distinctive geometric incised, stamped or chip-carved decorations, which are filled with white paste made from burnt bone powder (Sauter and Rossmanith 1966; Burger 1985). Alb-Hegau ware was further decorated with graphite and red paint, producing highly complex and diverse geometric motifs.

After 620/600 BCE, white ground red and grey painted ware appears. Such ceramics are no longer incised but instead contain dark grey and red painted decorations on a cream/white background. Motifs remain geometric and imitate those also seen on Alb-Hegau pottery (Dämmer 1978). The transition between the production of Alb-Hegau ware and white ground pottery probably encompasses a shift from pottery production in individual specialist workshops, to a system of more centralised production, with the Heuneburg marking a central supplier of decorated ceramics for the wider region (Stegmaier 2021, 100).

By phase Hallstatt D2 (starting around 540/530 BCE), Alb-Hegau pottery is no longer produced, and the production of white ground red and grey painted ware has started to dwindle. Instead, new ceramic forms appear. This includes red-polished vessels with black painted decorations, which are produced to a high standard with thin walls and decorations that imitate Mediterranean motifs (Stegmaier 2016, 90; 2021, 103). The scale of production of such vessels never matches that of white ground red- and grey painted ware, suggesting that such vessels were luxury items (Stegmaier 2016, 90). Imported ceramics start to be introduced to the site under the influence of increasing trade links with the Mediterranean world, particularly with Greek colonies such as Massalia (Marseille). These imported ceramics include types like the oinochoe, krater and kylix, luxury fine wares associated with serving and drinking liquids like wine (Kimmig 2000).

From phase Hallstatt D3, we also find a new type of local vessel, which is produced with the help of the potter’s wheel. Such geriefte Drehscheibenkeramik (i.e. wheel-turned pottery), often bowls, jugs or cups, is distinguished by several horizontal grooves running along the shoulder or neck of the vessels, as well as by a black or dark-grey coloured body. There is variation in the production processes underpinning such vessels, with some being shaped by hand through coiling, with careful burnishing of the vessel body, while others being produced through coiling, and then finishing the vessel on the wheel, or through wheel-throwing proper (Lang 1974, 3). At the Heuneburg, ceramics, alongside imported drinking paraphernalia from the Mediterranean region, were predominantly utilised for the consumption of fermented drinks such as wine and beer (Mötsch et al. 2019; Rageot et al. 2019). The appearance of wheel-made pottery reflects a dramatic shift in the standard repertoire of ceramics that was consumed at the Heuneburg and in the rest of West-Central Europe (Augier et al. 2011; Tappert 2012), with wheel-made pottery now corresponding to a break with older ceramic forms as well as the technological traditions that produced them. In this phase, we also see the appearance of omphaloi, which are bowls with a strongly concave base in the shape of a ‘navel’ or omphalos. Omphalos bowls, made of clay or metal, first appeared in the eastern Mediterranean region and Etruscan territories, where they were used in libation rituals (Cook 1968; Carol 1978). Given their Mediterranean character, these vessels have been considered imports to the Heuneburg. Three fragments of such bowls were included in the current sample.

Current issues in understanding the spread of the potter’s wheel in Central Europe

The use of the potter’s wheel, and in particular the mastery of Rotational Kinetic Energy (RKE) to throw ceramics from a lump of clay, requires significant skill obtained through extended periods (up to ten years) of training and observation (Roux and Corbetta 1989; Roux 2019). The introduction of this technology tends to be characterised by discontinuities in levels of skill, but also often other aspects of the ceramic production process and even the individuals involved. The adoption of the potter’s wheel (whether for wheel-throwing or other shaping practices involving RKE) has thus been approached as a ‘discontinuous’ innovation, which, contrasting to continuous innovations, rapidly transforms the ceramic production process (Roux 2010, 222).

Despite the significance of the shift to using potter’s wheels, in terms of the transformative nature of the motor skills and toolset needed, little is known about the origin and mechanisms of transmission underpinning the spread of this technology. Studies of wheel-turned ceramics from the Heuneburg point to links with the Mediterranean Region as the source of skills and knowledge relating to this innovation (Benoît 1965; Lang 1974). A Mediterranean link is suggested by typological similarities between locally made wheel-made pottery and Phocaean ceramics, related to products from the eponymous site in western Turkey and its western colonies such as Massalia in southern France. Nevertheless, the dark colour of the wheel-made ceramics and fine polished surfaces are instead more likely to reflect common features of Hallstatt ceramics (Benoît 1965). Other links are drawn with Etruscan ceramics from central Italy (Lang 1974). In a recent article, Nebelsick et al. (2022) explore the relations between the Golasecca culture and the area of the princely seats, considering Northern Italy as a key region for the transfer of Mediterranean products and technologies towards the north.

Next to questions about the origins of the potter’s wheel, recent research focuses on the specifics of the transmission mechanisms underpinning its spread (Kern et al. 2012). Such work points out that extensive interactions and learning processes underpin the adoption of complex innovations like the potter’s wheel, so that visual similarities with distant ceramics assemblages alone cannot explain the transmission of this technology. More specifically, Roux (2010) points out that social systems that facilitate technological skills transfer relating to ‘discontinuous’ innovations like the potter’s wheel tend to be marked by specific characteristics. Firstly, the system within which such innovations are transmitted tends to be ‘fragile’, i.e. consisting of a small group of participants only, in which the survival of skills is more precarious than in larger, more ‘robust’ systems (Roux 2010, 228). Secondly, discontinuous innovations are generally actualised within ‘closed’ systems (i.e. systems in which participants do not exchange information with external actors). For example, the adoption of the potter’s wheel in the Iberian Peninsula, took place first within a close fragile system (i.e. Phoenician coastal colonies), before the skills were adopted and transmitted more widely across Iberia (e.g. de Groot and Bloxam 2022; de Groot 2021). In the regions north of the Alps, a similar situation can be observed, as the potter’s wheel was first used in the relatively restricted context of the so-called ‘princely seats’, after which the technology spread more broadly to lowland and eastern settlements (Tappert 2012), thus suggesting a shift from transmission within a closed-fragile to an open-technological system.

A further consideration is the question of why this technology was adopted. In explaining the adoption of the potter’s wheel in the Czech Republic, Thér et al. consider the difference between product versus process innovations (Thér et al. 2017). By product innovation, the authors mean the selection of a set of performances achievable through a certain technique. In product innovation, the desire for the ‘product’ thus drives the technological change process. Process innovation, on the other hand, is the situation in which performances of the manufacturing process are selected for (Thér et al. 2017, 1259). Variation observed in the shaping methods to produce the new wheel-made drinking vessels (bowls and flasks) shows that the desire for the product was greater than the need to accurately copy the technological process. In this context, the potter’s wheel is interpreted as a product innovation (Thér et al. 2017, 1284). In order to understand the adoption of the potter’s wheel within settlements such as the Heuneburg, it is thus important to consider both technological variability underpinning wheel-made pottery production, as well as the specific functions that such pottery held within society.

Technological variation among early wheel-turned pottery at the ‘princely seats’

Mineralogical analyses of Late Hallstatt period ceramics on so-called ‘princely’ settlements have been conducted since the 1980’s, including at sites such as the Breisacher Müsterberg (southwest Germany) (Balzer 2009), Mont Lassois (central France) (Kilka 1986; Ramseyer 1999; Balzer 2009, 2010), Châtillon-sur-Glâne (Switzerland) (Maggetti and Galetti 1980; Kilka 1986; Ramseyer 1999), the Üetliberg and Baarburg (Switzerland) (Béarat and Bauer 1994) and Bourges (central France) (Augier et al. 2011; Augier 2012; Augier and Pauly 2014).

Petrographic analyses of ceramics from the Breisacher Münsterberg demonstrate that, from the Late Urnfield- to the Early La Tène periods, grog tempering was common in the production of both hand-made and wheel-made pottery (Balzer 2009, 104–113; 2010). Within the wheel-made ceramics, Balzer (2009) finds the use of grog, although it is generally finer and less abundant than within the production of hand-made pottery. A comparative analysis of petrographic analyses of other sites with wheel-made pottery, including Mont Lassois and Merxheim, demonstrates that such ceramics generally contained abundant quartz, but also contained some grog temper (Balzer 2009, 134, Fig. 62). Sandy tempers for the production of wheel-made pottery were also mentioned for the Üetliberg and Baarburg, as well as Châtillon-sur-Glâne. In most places, the recipes used for the production of hand-made pottery differ from that of wheel-made pottery, except in Bourges where a silicate-rich fabric was used throughout the La Tène period (Augier et al. 2011, 585).

Materials and methods

To provide insights into the technological procedures underpinning ceramic production at the Heuneburg during the Late Hallstatt period, an extensive analysis of ceramic thin sections from the phases D1 to D3 was conducted. Thin Section Ceramic Petrography (TSCP) was used to determine the mineralogical composition of ceramic fabrics and study technological features such as tempering and clay preparation strategies, shaping, surface treatment and heat treatment (Quinn 2013).

The technological analysis of ceramics from the Heuneburg using ceramic petrography has been attempted prior to this current study on several occasions. In light of a 1970’s study of painted wares from Hallstatt D1 phases at the Heuneburg, under the direction of Heinz-Werner Dämmer, a large number of thin sections were made from ceramic fragments and vessels excavated between 1950 and 1973 (Dämmer 1978). A publication on these thin sections, announced in the 1978 volume (Dämmer 1978, 80), never appears to have materialised. Fifty-one of the thin sections produced, boxed-up and safely stored in the Landesamt für Denkmalpflege in Esslingen, were reanalysed by the first author of the current article. The samples could in most cases be matched to typological characteristics and archaeological context, owing to their excellent study and publication in the 1970’s. As a result, it transpired that thin-sections corresponded to white ground red and grey painted ware, Alb-Hegau ware, red-polished and black painted ware and characteristic Kegelhals vessels, which are found across the northern foothills of the Alps and southern Central Europe (see Supplementary Information).

A second batch of thin-sections was prepared in the context of a study of Late Hallstatt ceramics by Helga van den Boom (1989) and Daniela Fořt-Linksfeiler (1989). These 24 thin sections of ceramics from diverse contexts and types were analysed and published by Maggetti (1989). Maggetti distinguished four main fabric groups (types 1–4), subdividing into a total of nine variations within these groups. The main distinguishing factor between these main groups is the matrix, being composed of calcareous or non-calcareous clay in different varieties of density and abundance of inclusions in fine fraction. Diachronic and typological observations were unfortunately not taken into consideration in his study.

An additional petrographic examination of a sample of 21 ceramics was conducted in light of the BEFIM study of pottery residues by a team from Leiden University, under the direction of Professor Annelou van Gijn (van Gijn et al. 2019, 2020). BEFIM: ‘Bedeutungen und Funktionen mediterraner Importe im früheisenzeitlichen Mitteleuropa’ was a collaborative research project directed by Professor Philipp Stockhammer, Professor Dirk Krausse, Thomas Hoppe M.A. and Professor Cynthianne Spiteri and running between 2015 and 2018, focused on understanding the meanings and functions of imported Mediterranean vessels in Early Iron Age Central Europe (Stockhammer 2019; Rageot et al. 2019) (https://www.befim.gwi.uni-muenchen.de/). Van Gijn and colleagues developed an experimental methodology to reconstruct vessel biographies for a range of coarse and fine ware vessels from phases Hallstatt D1-D3, revealing aspects of production and technology, shaping and considering vessel functions through use-wear analyses (van Gijn and Verbaas 2020). Petrographic analysis revealed four main groups including a muscovite rich group, a quartzite enriched group, a carbonate-limestone group and a mixed sedimentary and carbonate group (Braekmans and Jacobs 2020). This study also encompassed SEM–EDS analyses and a study of use-wear on the samples.

The current article combines, for the first time, all the aforementioned petrographic samples in order to create a full diachronic understanding of the development of the mineralogical composition, technological features such as tempering and clay preparation strategies, shaping, surface treatment and heat treatment of ceramics from Hallstatt periods D1-D3 at the Heuneburg. In addition to these earlier studies that are now integrated, 15 new thin-sections were made from phases D1 and D3. The aim of this was to address with specificity the question of how the fabrics of hand-made and wheel-made ceramics differ, to consider the trajectories of adoption and potential abandonment of early technical skills corresponding to the appearance of the innovation of the potter’s wheel in the Heuneburg region. In the selection of wheel-made vessels, our study was reliant on the sampling strategies of previous studies and current regulations regarding the use of destructive sampling methods. We were thus able to include a sample of nine wheel-made vessels, deriving from a single occupation phase (Hallstatt D3) and corresponding to a highly standardised ceramic type (geriefte Drehscheibenkeramik).

Thin sections of this latter group were prepared in the finds processing and thin section laboratory of the School of History, Classics and Archaeology of the University of Edinburgh. The analysis of all 111 samples were conducted by the first author using a GX polarising light microscope. Ceramic fabrics were recorded and separated into fabric groups based on mineralogical and structural variations utilising a description system proposed by Whitbread (1989, 1995) and modified by Quinn (2013). Microphotographs were made using a Leica MC170 HD polarising microscope and camera. Fabric descriptions and microphotographs are shown in the Supplementary Information.

Results

Summary of fabric groups

Building and expanding on Maggetti’s (1989) system, five fabric groups were distinguished and further divided into fourteen subgroups (Tables 1 and 2, Fig. 5). Main groups were distinguished by the specifics of the matrix, being composed of either calcareous clay with fine silicate and mica inclusions (type 1), fine calcareous fabric (type 2), non-calcareous clay with fine mica (type 3), fine non-calcareous clay (type 4) and a metamorphic (gneiss) fabric (type 5). The main modification to Maggetti’s grouping was the decision to make a separate fabric group for the gneiss-rich ceramic (type 5), which includes clays and temper deriving from a metamorphic source, contrasting with the other fabrics, which are more likely to derive from sedimentary sources and are very distinct from type 5.

Microphotographs of main fabric groups distinguished within the sample. (1) Calcareous matrix with abundant fine inclusions (the brown inclusion depicted is a clay pellet); (2a) dense calcareous matrix with calcite and grog; (2b) dense calcareous matrix with calcite; (2c) calcareous matrix with sand temper; (2d) very dense calcareous matrix with calcite and grog; (3a) silicate matrix with fine inclusions and grog; (3b) silicate matrix with fine inclusions; (4a) dense silicate matrix with calcite; (4b) dense silicate matrix with calcite and grog; (4c) dense silicate matrix with grog; (4d) silicate matrix with sand temper; (5) muscovite gneiss fabric

Within these main groups, subdivisions were made based on the inclusions in coarse fraction, which in most cases appear to have been added as temper. Most prominent is the use of grog temper, appearing in subgroups 1, 2a, 2d, 2e, 3a, 4b and 4c. Grog, which is made of fired and crushed pottery sherds, could be clearly distinguished in the samples due to the sharp boundaries and angular character of the fragments and their general prolate shape. The sorting and nature of the inclusions in the grog fabric often differ from the fabric of the host vessel and in some cases the inclusions are aligned parallel to the fragment’s margin. Clay pellets and argillaceous rock fragments also appear in some samples, either alongside grog or other types of temper. Clay pellets with amorphous or rounded shape and fine inclusions appear rarely alongside grog or mineral temper suggesting that clays were generally well-kneaded and purified prior to tempering (Holmqvist 2022).

Grog was utilised in the production of ceramics made of clay from both calcareous and non-calcareous origin, suggesting that the choice of clay and temper were not fixed to a set recipe; clay sources and choices of temper appear to have been utilised interchangeably. Further variations within the grog-tempered groups occur with additional tempers (e.g. crushed calcite, shells). Sand tempered fabrics (2c and 4d) represent a final notable sub-group, in which well-sorted silicate inclusions (including quartz and feldspar) were added to either calcareous or non-calcareous clays. Silicate inclusions are well-sorted and of similar size. We consider that these fabrics are sand-tempered because the inclusions in the matrix have a bimodal grain size distribution, which is uncommon in nature, and because the matrix is generally very fine, often excluding inclusions of a similar nature as the minerals in coarse fraction.

The presence of graphite-decorated Alb-Hegau ware indicates that the Heuneburg potters had excellent control over the firing process. In oxidising conditions, graphite applied to the surface of vessels quickly burns off after temperatures reach 700° C. Graphite-decorated pottery thus requires a sustained reducing atmosphere as temperature rises (Amicone et al. 2020). The alteration of calcite in fabrics 2a, 2b and 2d suggests that firing temperatures were approaching at least 750° C and therefore that potters were able to create a suitable atmosphere to retain the graphite decoration. Firing procedures for the production of white ground red and grey painted ware will have been different, requiring oxidising temperatures. Thus, potters were able to move between different technological procedures with the production of different types of vessels. Further archaeometric research is necessary to provide a more precise estimation of the dynamics between firing procedures and the specifics of the surface treatments used in the production of different vessel types.

Regarding the provenance of the raw materials, the results conform to the expectation that they were sourced locally. Calcareous as well as non-calcareous clays are present in the geology of the site’s immediate surroundings. Temper materials such as mixed sand can be found deposited along the banks of the Danube River, while the use of grog as a source of temper is equally a raw material that is easy to obtain locally. The only fabric that might point to a distant source is the gneiss fabric (type 5). While isolated gneiss fragments present in some of the samples could have been part of the mixed riverine deposits next to the Heuneburg, the abundance of gneiss and homogeneity of the matrix in fabric 5 (containing individual minerals we expect within clays forming upon gneiss geology) suggests that this fabric might have been imported from a distant region. The closest gneiss geology is located at a distance of about 80 km west of the Heuneburg.

Chronological observations

Most of the analysed samples could be traced back to their chronological context, at either site-level or the broader chronological groupings of Hallstatt D1–D3. The trajectory of change in the Heuneburg ceramic production between Hallstatt phases D1, D2 and D3 is significant because ceramic production underwent a substantial transformation, from the production of hand-made painted and pattern burnished ware to the use of imported fine ware and local production of wheel-made ceramics. This shift is reflected in our sample set, which includes Alb-Hegau ware, white ground red and grey painted pottery, red polished dark-painted pottery, wheel-turned wares and omphaloi.

Within the dataset there are 46 samples that date to phase Hallstatt D1, 12 samples that date to phase Hallstatt D2, 23 samples that date to phase Hallstatt D3 and 30 samples for which a precise chronology could not be established (see Supplementary Information). Figure 6A shows the distribution of fabric types through the different Hallstatt phases at the Heuneburg. The yellow/sand coloured bars on the graph reflect fabric groups with a calcareous base clay (fabric groups 1 and 2). Fabrics made from non-calcareous clays are represented in blue (fabric groups 3–5). The figure demonstrates that calcareous and non-calcareous fabric groups are represented in all phases. Furthermore, fabrics containing grog temper (fabrics 1, 2a, 2d, 3a, 4b and 4c) appear in all phases suggesting that grog tempering was a prominent technological choice at the Heuneburg throughout the Late Hallstatt period. A significant trend, however, can be distinguished, which is that calcareous clay fabrics, common in Hallstatt D1, decline in number throughout the phases, while non-calcareous fabrics are more frequently represented in phase Hallstatt D3 compared to calcareous fabrics. Figure 6B shows that the shift to the use of non-calcareous clay is correlated with two processes. The production of white ground red and grey painted ware (WGRP) is prevalent in Hallstatt D1 and corresponds mainly to calcareous clay fabrics (fabric group 2). Five samples within the Hallstatt D1 dataset are classified as Alb-Hegau ware (A–H), and all of the samples are made from a different fabric, being either calcareous or non-calcareous. Red polished black painted ware (RPBP) is generally made from fabric 2d (very dense calcareous matrix with calcite and grog), except for in phase Hallstatt D2, where a sample is made from non-calcareous clay (4b). Thus, the hand-made fine ware, which characterises ceramic production in phase Hallstatt D1 at the Heuneburg, is predominantly made from calcareous clays, with different mixtures of temper (using grog, crushed calcite or mixed silicate inclusions).

Stratification and chronological distribution of fabric and ceramic types. A Sum of samples of different fabrics in each site-phase. B Sum of samples of different fabrics in each site-phase, labelled by ceramic type. A–H Alb-Hegau ware; DSK: wheel-turned pottery; handmade: hand-made fine ware; RPBP: red-polished black painted ware; unknown; WGRP: white ground red and grey painted ware

One possible anomaly in the sample is a single Alb-Hegau sherd found in a context belonging to phase Hallstatt D2. Alb-Hegau ceramics are no longer produced in this phase, so this particular sherd might be an intrusion from a lower level.

Wheel-turned pottery (DSK) is often made from non-calcareous clay with silicate temper (fabric 4d). The quartz, quartzite and feldspar temper used is generally fine (mode = 0.2 mm), well-sorted and dominant in coarse fraction. The added tempers in coarse fraction are on average smaller than the grog and calcite tempered fabrics common across the other pottery types, and it is likely that this difference corresponds to the different production methods utilised in the category of wheel-made pottery. The combination of using non-calcareous clay and sand temper is significant.

The use of smaller tempers is common in the production of wheel-made pottery because smaller tempers do not abrade the potter’s hands in the process of wheel-throwing or wheel-shaping using RKE to the same extent as larger tempers would. Similarly, finer tempers will not cause marring or tearing of the wall surface during the throwing process (Sinopoli 1991; Rice 2015).

Non-calcareous clays are generally more malleable than clays with calcite, which could be suitable during the wheel-throwing process. Non-calcareous clays also respond differently to heat treatment, sintering at higher temperatures and thus avoiding the spalling and lime popping common in highly fired calcareous ceramics. Thus, it could be that, in combination with different firing treatments and the introduction of RKE in the shaping process, the choice of a non-calcareous fabric (4d) with fine temper was preferred over the use of calcareous tempers common in the production of hand-made fine ware. That being said, calcareous clays were the material of choice for wheel-thrown vessels in other parts of Europe and the Mediterranean during the Iron Age, for example in the context of Phoenician ceramic production in Spain and the Levant (de Groot 2021). The choice of clay thus primarily reflects the knowledge, experience and preference of the potter rather than its specific functional advantages alone.

Fabric 4d was already used for the production of hand-made pottery in phase Hallstatt D1, so it is likely that potters selected the fabric that was considered most suitable from a range of available options. A driver for this selection could be to avoid largely angular (and thus sharp) grains when working with RKE, thus favouring more fine-grained fabrics to improve handling workability.

A final observation is that the three sherds identified as omphalos bowls are made of non-calcareous fabrics consistent with other samples in phase Hallstatt D3 (fabric 4c and 3b). It is thus likely that such bowls were produced locally rather than imported to the site. The highly polished, dark surfaces of such vessels also resemble that of the wheel-made ceramics produced in this phase, suggesting that there was significant overlap in the technological procedures used to treat the surfaces of omphaloi and wheel-made pottery in this phase.

Discussion

Clay and temper recipes changed during the Late Hallstatt period at the Heuneburg alongside the development of new ceramic types, most notably the uptake of the potter’s wheel for producing dark-burnished and grooved cups, jars and bowls in phase Hallstatt D3. Hand-made fine ware from phase Hallstatt D1 was produced according to complex decoration practices and firing treatments but the fabrics utilised to produce such ceramics varied; white ground red and grey painted ware seems to have been made exclusively from calcareous clays whilst potters selected various fabrics for producing Alb-Hegau ware. With the integration of the potter’s wheel, non-calcareous fabrics became more frequent, in particular fabric 4d, which was exclusively used for the production of wheel-turned pottery in phase Hallstatt D3. Thus, our results confirm that the diachronic changes observed in the ceramic repertoire of the Late Hallstatt period are also reflected in the use of ceramic clay and temper.

Compared with observations from other important settlements in West-Central Europe, these observations broadly align. Like at other major central places in this region, wheel-made pottery at the Heuneburg was made from clays with silicate inclusions, of finer dimensions than within hand-made pottery. Grog tempering is common at other settlements such as Breisach Münsterberg, where this type of temper not only appears in hand-made pottery, but also in wheel-made pottery alongside fine silicate inclusions. Our analysis did not find evidence for grog tempering in wheel-made pottery pointing to variation in the recipes utilised for the production of wheel-made ceramics across the ‘princely seats’ region. Such contemporary variation in the fabrics used for the production of early wheel-made pottery in Central Europe might be significant, as it could point to differences in transmission trajectories and/or local innovations within the ceramic production process during the introduction of the potter’s wheel.

The adoption of the potter’s wheel: An endogenous or exogenous process?

Ongoing archaeological and anthropological studies have demonstrated that the adoption of motor skills and technological knowledge relating to the use of the potter’s wheel can take many years to perfect, suggesting that direct learning through instruction by an expert teacher is needed (Roux and Corbetta 1989; Roux and Courty 1998; Roux 2003, 2019). The spread of the potter’s wheel tends to be marked by technological ‘discontinuities’ with respect to other forms of ceramic production, in which all elements of the chaîne opératoire change alongside the introduction of the new shaping methods. Because the chaîne opératoire marks meaningful technological variation, which is specific to the social groups employing such techniques (Leroi-Gourhan 1964), it is sometimes postulated that the clean break between one chaîne opératoire and the next corresponds to a change in the composition of the crafting community of a given society (Roux 2019). This could be the case in Iron Age northern Spain, where the introduction of the potter’s wheel coincided with the spread of a new clay recipe using only fine silicate tempers and non-calcareous clays (de Groot et al. 2023). Thus, for northern Spain, it has been considered likely that the spread of the potter’s wheel (alongside the double chambered kiln) took place through an exogenous process, in which potters bringing such innovations operated largely in isolation from earlier and ongoing hand-shaping traditions.

For Central Europe, a similar line of interpretation has been posed by Nebelsick et al. (2022). Despite the local character of the raw materials utilised in the production of geriefte Drehscheibenkeramik, their style and decoration could be seen as evidence of itinerant potters, most likely linked to the northern Italian Golasecca culture. However, in light of the continuity between the fabrics used for the production of hand-made pottery in Hallstatt D1 and wheel-made ceramics from Hallstatt D3, revealed by the current study, we consider that a different scenario could also be possible for the Heuneburg. Although wheel-made pottery was produced using a set fabric (4d), this fabric was not new within the Heuneburg; it already appears in phase Hallstatt D1 for the production of hand-made fine ware. This suggests some degree of continuity in the production of ceramics alongside the introduction of the potter’s wheel, potentially reflecting continuity within an ongoing lineage of craft specialists. We thus consider that the adoption of this technology formed part of an endogenous process, in which local potters integrated the potter’s wheel into an existing chaîne opératoire.

Specialisation, demand and innovation

In order to explain the mechanisms underpinning the adoption of the potter’s wheel at the Heuneburg, we can consider here the difference between robust-open and fragile-closed technological systems proposed by Roux (2010). For the Heuneburg region, it is likely that pottery production was carried out by a relatively small group of experts, operating within a closed system in which skills were not broadly transmitted from the Hallstatt C period onwards (Dämmer 1978; Kimmig 1983; Gersbach 1995; Stegmaier 2021). The reason for this suggestion is that pottery types like Alb-Hegau and white ground red and grey painted ware were produced at the Heuneburg, and for local and regional demand. This would indicate that a group of craft specialists operated locally at the site and probably closely controlled the transmission of technological skills for producing such pottery types.

Despite the probably relatively small group of individuals partaking in the production of ceramics, it is likely that the system in which they operated was fairly robust, because the demand for hand-made fine ware vessels produced at the Heuneburg appears to have been widespread and continuous throughout Hallstatt D. The organisation of specialised production may thus be characterised by ‘individual’ rather than ‘attached’ specialisation (Brumfiel and Earle 1987; Roux and Corbetta 1989; Costin 1991). Individual specialisation occurs when potters specialise in the production of specific vessel types for unspecified demand, while attached specialisation appears when production is directed to and facilitated by a patron (Brumfiel and Earle 1987, 5). Attached specialisation can be considered particularly fragile, because when the governing patron (or members of the elite) disappears, specific demand would also disappear (Baldi and Roux 2016). In the case of the Heuneburg, there is no evidence to support a scenario in which pottery was only produced for the elites (i.e. ceramics appear not exclusively in elite graves, but also in domestic contexts, and were thus probably consumed by all members of society). Thus, instead of a ‘fragile’ attached form of specialisation, it is more likely that the technological system was fairly robust, responding to demand from a broad population within and outside the Heuneburg.

It is likely that this demand for ceramics is connected to eating and drinking habits, a relationship that has been studied through Organic Residue Analysis (ORA). Within the sample analysed in the context of the present study, 11 samples from Hallstatt D1 have ORA results, obtained in the context of the aforementioned BEFIM project (Stockhammer and Fries-Knolbach 2019). Three samples correspond to hand-made fine ware from the lower town; one contains beeswax, bacterial fermentation product and bark tar, while the other two contain dairy lipids, plant wax and millet. Hand-made fine ware samples from the outer settlement contain bacterial fermentation product, animal fat and plant wax, while samples from the hilltop plateau contain dairy lipids, beeswax, plant wax and millet. One sample of white ground red and grey painted ware from the hilltop plateau contains animal fat, beeswax and plant wax.

The results are consistent with the observations published in Rageot et al. (2019), which consider that beeswax is common in drinking vessels from sixth century BCE phases at the Heuneburg. Beehive products were probably used to make alcoholic beverages such as mead or to sweeten wine, which was already imported and regularly consumed by phase Hallstatt D1. Wine mixtures could reflect the adoption of Mediterranean-style libation practices, in which the combination wine-honey-milk is a common recipe for such rituals (Nebelsick 2020; Nebelsick and Metzner-Nebelsick 2023). Mixed residues of plant waxes, dairy, animal lipids and millet are common, indicating some vessels were reused for different food preparation and consumption practices. Millet, dairy and beehive products are the most dominant residues from the plateau, while beeswax and bacterial fermentation products are more prevalent in the outer settlement, suggesting that this location was important for the consumption of fermented beverages.

From the later phases, only one fragment within the analysed dataset has produced residue evidence. This pertains to a wheel-made bottle containing fruit product, probably from grape wine and pine tar. This sample is representative of the wider trend obtained through residue analyses, that grape wine products appear almost exclusively in wheel-made pottery and imported Mediterranean drinking vessels from phase Hallstatt D3 (Mötsch et al. 2019; Rageot et al. 2019). Notably, fermented beverages including wine were already consumed in the previous phases, indicating that the trade in such products precedes the adoption of the potter’s wheel and introduction of imported Attic pottery.

The demand for new types of pottery, including imported Attic ware and wheel-made ceramics thus developed alongside the growing connectivity with settlements in the Mediterranean Region and the popularity of the consumption of fermented beverages, most likely in combination with new feasting practices. Residue analyses that have been conducted in light of the BEFIM project point out that wine drinking preceded the adoption of wheel-made pottery and might thus have been a stimulus for the import of Mediterranean style drinking vessels and the local production of wheel-made fine-ware (Rageot et al. 2019). Technological transformations in the production of ceramics at the Heuneburg might thus have been at least partially ‘driven by drink’ (sensu Dietler 1990), with a potentially widespread uptake of such new consumption practices by urbanising populations across southern France as well as the area of the ‘princely seats’. This supports the view of Thér et al. (2017), that the spread of the potter’s wheel could be a product innovation, where wheel-made drinking and serving vessels were sought after, while the specific process to produce these was a lesser driver of this innovation.

Conclusion

This article demonstrates the value of revisiting and combining separate datasets of thin-sections to develop a more complete understanding of pottery production at so-called Late Hallstatt ‘princely seats’ like the Heuneburg. The study has been particularly informative for diachronic trajectories of technological change taking place alongside the adoption of the potter’s wheel, offering new perspectives on questions surrounding the transmission of technological skills, processes of labour specialisation and the impact of novel consumption practices on ceramic technology. The continued production of hand-made fine ware in Hallstatt D3, as well as the evidence for continuity in raw material selection demonstrated in this paper, indicates that this innovation was integrated into—rather than replacing—ongoing social and technological practices.

A topic that can be further explored relates to the routes via which new skills arrived at the Heuneburg (e.g. via other ‘princely seats’, through trans-Alpine links with the Etruscans or indirectly through the Phocaean colonies along the French Mediterranean coast). A more extensive comparative analysis of clay recipes alongside refined chronological analyses, integrating sites in, for example, the Golasecca region of Northern Italy (as suggested by Nebelsick et al. 2022), could be useful in exploring such links more fully. In this context, our study offers an important starting point for future comparative analyses, as well as providing novel insights into the organisation of production at the dawn of urbanism in Central Europe.

Data availability

The data used during the study are available in the Supplementary Information. Materials used for the study are available upon reasonable request.

References

Amicone S, Radivojević M, Quinn PS, Berthold C, Rehren T (2020) Pyrotechnological connections? Re-investigating the link between pottery firing technology and the origins of metallurgy in the Vinča Culture, Serbia. J Archaeol Sci 118:105123. https://doi.org/10.1016/j.jas.2020.105123

Augier L (2012) Versuche zur Keramiktechnologie am Ende des 6. und 5. Jahrhunderts v. Chr. in Bourges (Cher, France): Scheibengedrehte Keramik und Stempelverzierung. In: Kern A, Koch JK, Balzer I, Fries-Knoblach J, Kowarik K, Later C et al. (eds) Technologieentwicklung und -transfer in der Hallstatt- und Latènezeit. Beier & Beram, Langenweissbach, pp 117–120

Augier L, Balzer I, Bardel D, Defressigne S, Bertrand E, Fleischer F et al (2011) La céramique façonnée au tour, témoin privilégié de la diffusion des techniques au Hallstatt D et à La Tène A/B1. In: A. Colin A, Verdin F (eds) L’âge du fer en Aquitaine et sur ses marges: mobilité des hommes, diffusion des idées, circulation des biens dans l’espace européen à l’âge du fer. Fédération Aquitania, Bordeaux, pp 563–594

Augier L, Pauly S (2014) Les productions céramiques du site princier de Bourges (dép. Cher) entre la fin du 6e et le début du 4e siècle av. J.-C.: identification des techniques de façonnage au tour lent, caractérisation pétrographique et interprétation des modes de production. Archäologisches Korrespondenzblatt 44(2):195–214. https://doi.org/10.11588/ak.2014.2.89890

Baldi J, Roux V (2016) The innovation of the potter’s wheel: a comparative perspective between Mesopotamia and the southern Levant. Levant 48(3):236–253. https://doi.org/10.1080/00758914.2016.1230379

Balzer I (2009) Chronologisch-chorologische Untersuchung des späthallstatt- und frühlatènezeitlichen ‘Fürstensitzes’ auf dem Münsterberg von Breisach (Grabungen 1980–1986). Konrad Theiss Verlag, Stuttgart

Balzer I (2010) Der Breisacher Münsterberg zwischen Mont Lassois und Most na Soči. In: Erzsébet J, Schönfelder M, Wieland G (eds) Nord-Süd, Ost-West: Kontakte während der Eisenzeit in Europa: Akten der internationalen Tagungen der AG Eisenzeit in Hamburg und Sopron 2002. Archaeolingua, Budapest, pp 27–39

Béarat H, Bauer I (1994) Früheisenzeitliche Keramik von Baarburg ZG und Üetliberg ZH. Germania 72(1):67–93

Benoît F (1965) Recherches sur l’hellénisation du Midi de la Gaule. Éditions Ophrys, Aix-en-Provence

van den Boom H (1989) Keramische Sondergruppen der Heuneburg. Philipp von Zabern, Mainz

Braekmans D, Jacobs L (2020) Microstructural investigation on a selection of the Heuneburg Iron Age ceramic assemblage. In: van Gijn AL, Fries-Knoblach J, Stockhammer PW (eds) Pots and practices: An experimental and microwear approach to Early Iron Age vessel biographies. Sidestone Press, Leiden, pp 193–204

Brumfiel EM, Earle TK (1987) Specialization, exchange and complex societies: an introduction. In: Brumfiel EM, Earle TK (eds) Specialization, exchange and complex societies. Cambridge University Press, Cambridge, pp 1–9

Burger I (1985) Analyseergebnisse zur Frage der Inkrustierung und Bemalung hallstattzeitlicher Gefäße von Riedenburg. In: Bernd E (ed) Archäologische Denkmalpflege in Niederbayern. 10 Jahre Außenstelle des Bayerischen Landesamtes für Denkmalpflege in Landshut (1973–1983). Bayerisches Landesamt für Denkmalpflege, München, pp 121–123

Carol C (1978) Two Omphalos Phialai. J. Paul Getty Mus J 6/7:131–138. http://www.jstor.org/stable/4166395

Cook BF (1968) A class of Etruscan bronze omphalos-bowls. Am J Archaeol 72(4):337–344

Costin CL (1991) Craft specialization: issues in defining, documenting, and explaining the organization of production. J Archaeol Method Theory 3:1–56

Dämmer HW (1978) Die bemalte Keramik der Heuneburg. Die Funde aus den Grabungen von 1950–1973. Romisch-Germanische Forschungen, Berlin

de Groot BG (2021) Material methods: Considering ceramic raw materials and the spread of the potter‘s wheel in Early Iron Age Southern Iberia. IANSA XII(2):1–12

de Groot BG, Badreshany K, Torres-Martínez JF, Fernández-Götz M (2023) Capturing technological crossovers between clay crafts: an archaeometric study on the emergence of workshop production in Late Iron Age northern Spain. PLoS One 18(5):e0283343. https://doi.org/10.1371/journal.pone.0283343

de Groot BG, Bloxam A (2022) Radiocarbon approaches for mapping technological change: the spread of the potter’s wheel in the Iberian Peninsula, 1000–0 BCE. J Archaeol Sci Rep 41:103288. https://doi.org/10.1016/j.jasrep.2021.103288

Dehn W (1963) Frühe Drehscheibenkeramik nördlich der Alpen. Alt-Thüringen 6:372–382

Dietler M (1990) Driven by drink: the role of drinking in the political economy and the case of early Iron Age France. J Anthropol Archaeol 9(4):352–406. https://doi.org/10.1016/0278-4165(90)90011-2

Dobres M-A (1999) Technology’s links and chaînes: the processual unfolding of technique and technician. In: Dobres M-A, Hoffman CR (eds) The Social Dynamics of Technology: Practice, Politics, World Views. Smithsonian Institution Press, Washington DC, pp 124–146

Dongus H (1977) Die Oberflächenformen der Schwäbischen Alb und ihres Vorlands. Selbstverlag des Geographischen Institutes der Universität Marburg, Marburg/Lahn

Fernández-Götz M (2018) Urbanization in Iron Age Europe: trajectories, patterns, and social dynamics. J Archaeol Res 26:117–162. https://doi.org/10.1007/s10814-017-9107-1

Fernández-Götz M, Krausse D (2013) Rethinking Early Iron Age urbanisation in Central Europe: the Heuneburg site and its archaeological environment. Antiquity 87(336):473–487. https://doi.org/10.1017/S0003598X00049073

Fernández-Götz M, Ralston I (2017) The complexity and fragility of Early Iron Age urbanism in West-Central temperate Europe. J World Prehist 30(3):259–279. https://doi.org/10.1007/s10963-017-9108-5

Fořt-Linksfeiler D (1989) Die Schüsseln und Schalen der Heuneburg. Philipp von Zabern, Mainz

German R (1989) Erdgeschichte in der Umgebung der Heuneburg. In: Gersbach E (ed) Ausgrabungen und Stratigraphie der Heuneburg. Phillip von Zabern, Mainz, pp 127–130

Gersbach E (1995) Baubefunde der Perioden IVc-IVa der Heuneburg. Phillip von Zabern, Mainz

Geyer OF, Gwinner MP, Geyer M, Nitsch E, Simon T (2011) Geologie von Baden-Württemberg. Schweizerbart, Stuttgart

Gosselain O (1992) Technology and style: potters and pottery among Bafia of Cameroon. Man 27(3):559–586. https://doi.org/10.2307/2803929

Holmqvist E (2022) Why not let them rest in pieces? Grog-temper, its provenance and social meanings of recycled ceramics in the Baltic Sea region (2900–2300 BCE). Archaeometry 64(S1):8–25. https://doi.org/10.1111/arcm.12727

Hopert S (1996) Frühe scheibengedrehte Keramik aus Südwestdeutschland und der Schweiz. Archäol Schweiz 19(1):18–27

Kern A, Koch JK, Balzer I, Fries-Knoblach J, Kowarik K, Later C et al (eds) (2012) Technologieentwicklung und -transfer in der Hallstatt- und Latènezeit. Beier & Beram, Langenweissbach

Kilka T (1986) Châtillon-sur-Glâne-Mont-Lassois-Le Pègue: étude comparative des céramiques sur la base d’analyses pétrographique minéralogique et chimique. Chronique Arch:116–127

Kimmig W (1983) Die Heuneburg an der oberen Donau. K Theiss, Stuttgart

Kimmig W (ed) (2000) Importe und mediterrane Einflüsse auf der Heuneburg. Philipp von Zabern, Mainz

Krausse D, Fernández-Götz M, Gutekunst A, Hansen L (2019) Size matters–A re-evaluation of the Heuneburg demography. Germania 97:179–189

Krausse D, Fernández-Götz M, Hansen L, Kretschmer I (2016) The Heuneburg and the Early Iron Age princely seats: First towns north of the Alps. Archaeolingua, Budapest

Krausse D, Kretschmer I, Hansen L, Fernández-Götz M (2015) Die Heuneburg - keltischer Fürstensitz an der oberen Donau. Verlagsbüro Wais & Partner, Stuttgart

Lang A (1974) Die geriefte Drehscheibenkeramik der Heuneburg 1950–1970 und verwandte Gruppen. de Gruyter, Berlin

Leroi-Gourhan A (1964) Le geste et la parole. Technique et langage (Vol. 1). Albin Michel, Paris

Maggetti M (1989) Dünnschliffuntersuchungen an Schüsseln und Schalen der Heuneburg. In: van den Boom H, Fořt-Linksfeiler D (eds) Keramischen Sondergruppen der Heuneburg: Die Schüsseln und Schalen der Heuneburg. Philipp von Zabern, Mainz, pp 208–210

Maggetti M, Galetti G (1980) Composition of Iron Age fine ceramics from Châtillon-s-Glâne (Kt. Fribourg, Switzerland) and the Heuneburg (Kr. Sigmaringen, West Germany). JAS 7(1):87–91. https://doi.org/10.1016/S0305-4403(80)80008-2

Mötsch A, Rageot M, Schorer B, Gutekunst A, Balzer I, Cafisso S et al (2019) Mediterran genießen. Zum Gebrauch lokal hergestellter und importierter Keramik auf der Heuneburg im Spiegel von Nahrungsrückstandsanalysen. In: Stockhammer PW, Fries-Knoblach J (eds) In die Töpfe geschaut: biochemische und kulturgeschichtliche Studien zum früheisenzeitlichen Essen und Trinken. Sidestone Press, Leiden, pp 113–210

Nebelsick LD (2020) Celtic kykeon? New ceramological evidence for the appropriation of Mediterranean sympotic and libation practices in the 6th century BCE Heuneburg. In: Kobylinski Z (ed) Archaeologica Hereditas. Res Publica Multiethnica Foundation, Warsaw, Studies in archaeological ceramology, pp 17–21

Nebelsick LD, Balzer I, Metzner-Nebelsick C, Vanzetti A (2022) Between Genoa and Günzburg - a communication corridor or a void? In: de Marinis RC, Rapi M (eds) Preistoria e Protostoria in Lombaria e Canton Ticino. Firenze, Rivista di Scienze Preistoriche, pp 609–620

Nebelsick LD, Metzner-Nebelsick C (2023) Wein -Vom Göttertrank zum Gaumenkitzel Belege aus bronzezeit und früher Eienzeit. Archäol Deutschland 1(2023):28–31

Quinn PS (2013) Ceramic petrography: The interpretation of archaeological pottery related artefacts in thin section. Archaeopress, Oxford

Rageot M, Mötsch A, Schorer B, Gutekunst A, Patrizi G, Zerrer M et al (2019) The dynamics of Early Celtic consumption practices: a case study of the pottery from the Heuneburg. PLoS One 14(10):e0222991. https://doi.org/10.1371/journal.pone.0222991

Ramseyer D (1999) Les céramiques de Vix et Châtillon-sur-Glâne. Productions locales ou importations. In: Chaume B, Mohen JP, Périn P (eds) Archéologie des Celtes. Mélanges à la mémoire de René Joffroy. M Mergoil, Montagnac, pp 307–314

Rice PM (2015) Pottery analysis: A sourcebook, 2nd edn. University of Chicago Press, Chicago

Roux V (2003) A dynamic systems framework for studying technological change: application to the emergence of the potter’s wheel in the southern Levant. J Archaeol Method Theory 10(1):1–30. https://doi.org/10.1023/A:1022869912427

Roux V (2010) Technological innovations and developmental trajectories: social factors as evolutionary forces. In: O’Brien MJ, Shennan S (eds) Innovation in cultural systems. Contributions from evolutionary anthropology. The MIT Press, Cambridge & London, pp 217–234

Roux V (2019) Ceramics and society: A technological approach to archaeological assemblages. Springer

Roux V, Corbetta D (1989) The potter’s wheel: Craft specialisation and technical competence. Oxford and IBH Publishing, Oxford

Roux V, Courty M-A (1998) Identification of wheel-fashioning methods: Technological analysis of 4th–3rd millennium BC oriental ceramics. J Archaeol Sci 25(8):747–763

Sauter F, Rossmanith K (1966) Chemische Untersuchung von Inkrustationen in hallstattseitlicher Keramik. Archeol Austriaca 40:135–142

Sinopoli CM (1991) Approaches to archaeological ceramics. Springer, Cham

Stegmaier G (2016) The Heuneburg - A Centre of Pottery Production. In: Krausse D, Fernández-Götz M, Hansen L, Kretschmer I (eds) The Heuneburg and the Early Iron Age Princely Seats: First Towns North of the Alps. Archaeolingua, Budapest, pp 88–90

Stegmaier G (2021) Pottery production and the process of centralisation during the Early Iron Age: a case study on the Heunburg hillfort in Southwest Germany. In: Weidinger A, Leskovar J (eds) Interpretierte Eisenzeiten. Fallstudien, Methoden, Theorie. Tagungsbeiträge der 9. Linzer Gespräche zur interpretativen Eisenzeitarchäologie. Oberösterreichisches Landesmuseum, Linz, pp 97–106

Stockhammer PW (2019) Foreword. What did the early Celts drink? Meanings and functions of imported Mediterranean vessels in Early Iron Age Central Europe. In: Stockhammer PW, Fries-Knoblach J (eds) Was tranken die frühen Kelten? Bedeutungen und Funktionen mediterraner Importe im früheisenzeitlichen Mitteleuropa. Sidestone Press, Leiden, pp 13–16

Stockhammer PW, Fries-Knolbach J (eds) (2019) In die Töpfe Geschaut. Sidestone Press, Leiden, Biochemische und kulturgeschichtliche Studien zum früheisenzeitlichen Essen und Trinken

Tappert C (2012) Der Beginn der Drehscheibenkeramik im östlichen Frühlatènekreis und ihre Entwicklung bis zum Ende der Stufe Lt A. In: Kern A, Koch JK, Balzer I, Fries-Knoblach J, Kowarik K, Later C et al (eds) Technologieentwicklung und–transfer in der Hallstatt-und Latènezeit. Beier & Beran, Langenweissbach, pp 121–138

Thér R, Mangel T, Gregor M (2017) Potter’s wheel in the Iron Age in Central Europe: process or product innovation? J Archaeol Method Theory 24(4):1256–1299. https://doi.org/10.1007/s10816-016-9312-0

van Gijn AL, Fries-Knoblach J, Stockhammer PW (eds) (2020) Pots and practices: An experimental and microwear approach to Early Iron Age vessel biographies. Sidestone Press, Leiden

van Gijn AL, Jacobs L, Groat N, de Koning N, Braekmans D, Verbaas A (2019) Studying vessel biographies from the Heuneburg: an experimental approach. In: Stockhammer PW, Fries-Knoblach J (eds) Was tranken die frühen Kelten? Sidestone Press, Leiden, Bedeutungen und Funktionen mediterraner Importe im früheisenzeitlichen Mitteleuropa, pp 77–100

van Gijn AL, Verbaas A (2020) Microwear studies of pottery from the Iron Age site of the Heuneburg (Germany). In: van Gijn AL, Fries-Knoblach J, Stockhammer PW (eds) Pots and practices: an experimental and microwear approach to Early iron Age vessel biographies. Sidestone Press, Leiden, pp 121–150

Wallaert-Pêtre H (2001) Learning how to make the right pots: apprenticeship strategies and material culture, a case study in handmade pottery from Cameroon. J Anthropol Res 57(4):471–493. https://doi.org/10.1086/jar.57.4.3631356

Whitbread IK (1989) A proposal for the systematic description of thin sections towards the study of ancient ceramic technology. In: Maniatis Y (ed) Archaeometry: Proceedings of the 25th international symposium. Elsevier Science Publishers, Amsterdam, pp 127–138

Whitbread IK (1995) Greek transport amphorae: a petrological and archaeological study. British School at Athens, Athens

Acknowledgements

We would like to express our thanks to staff at the Landesamt für Denkmalpflege in Esslingen and Sabine Hagmann for their advice and help with accommodating a macroscopic study of their collection of Heuneburg ceramics. We are grateful to Leonie Rossi’s for sharing pottery data from her forthcoming doctoral thesis.

Funding

The present study was made possible by Beatrijs de Groot’s Early Career Fellowship, entitled ‘Economies of Innovation: tracing the potter’s wheel in Iron Age Southern Europe’, funded by the Leverhulme Trust (ECF-2019–081).

Author information

Authors and Affiliations

Contributions

Conception of idea (Beatrijs de Groot and Manuel Fernández-Götz), study design, introduction, methodology, materials and methods, thin-section petrography, archaeological overview, discussion, conclusions, illustrations (Beatrijs de Groot); introduction, archaeological overview, materials, discussion, illustrations, conclusions (Manuel Fernández-Götz, Leif Hansen, Gerd Stegmaier, Dirk Krausse), materials and methods, thin-section petrography (Dennis Braekmans).

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethic approval

The authors declare the integrity of the scientific record.

Consent to participate

All authors, read, reviewed, edited and approved the manuscript.

Consent for publication

All authors agree with the submission to Archaeological and Anthropological Sciences.

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

de Groot, B.G., Braekmans, D., Fernández-Götz, M. et al. Technological dynamics of Early Iron Age ceramics from the Heuneburg (SW Germany): A synthesis of 50 years of research. Archaeol Anthropol Sci 15, 129 (2023). https://doi.org/10.1007/s12520-023-01832-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-023-01832-2