Abstract

Compared with other gold plating processes, mercury gilding was widely used in ancient China due to the less consumption of gold and excellent adhesion between the gold layer and substrate. Herein, the comprehensive analyses of the silver crown and boots unearthed from the Consort Tombs of Emperor Shengzong (圣宗萧贵妃) of the Liao (辽) Dynasty reveal the surface composition and structural characteristics and also the unique multilayered structure and cross-sectional compositional distribution of the gold layer. First, the existence of mercury on the golden surface of cultural relics, as well as the unique porous structure and granular surface morphology, indicate that the artifacts were probably processed using mercury gilding. In addition, the intermetallic compound, i.e., Au5Hg, in the gold layer indicates that the processing temperature was 388–419 ℃; thus, the formation mechanism was the transformation of solid solution in the amalgam to intermetallic compound during the heating of Au-Hg system. Moreover, the cross-sectional transition layer is mainly composed of Ag and Hg due to the interstitial diffusion of mercury atoms at room temperature and vacancy diffusion of silver atoms during the heating process, bonding the gold layer with the substrate. Obviously, the bonding mechanism of the gold layer and substrate was interstitial diffusion and vacancy diffusion within the Ag-Hg system. The current work reveals the special multilayered cross-section of silver gilding relics and shows that mercury played a crucial role in both the formation of the gold layer and bonding between the gold layer and substrate during the silver gilding process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gold (Au) is one of the earliest precious metal materials used by mankind. Since its discovery, gold is considered as a symbol of wealth and social status in different cultures due to its bright color, high value, and corrosion resistance, originating from limited resources and availability (Liu et al. 2021). However, instead of pure gold objects, gold-like appearances are targeted due to the high cost of gold, leading to the development of surface decoration technologies (Singh and Singh 2019), such as foil gilding, leaf gilding (gold plating with some adhesives), gold inlay, and fire gilding (Oddy 1993, 1991; Leusch et al. 2015). The traditional fire gilding process originated in China in the fourth century BC and has been inherited for more than 2000 years (Liu et al. 2019; Yao 2019). According to the type and quantity of unearthed gilding products, fire gilding was one of the most widely used gold decoration processes in ancient China (Gao 2009; Jett 1993). The reason might be that fire gilding technology was able to join gold with another important metal, i.e., mercury (Hg), and the introduction of mercury and the heating process were the key factors of this technology. Mercury can chemically dissolve different metals and form amalgams, even with gold (Lins and Oddy 1975; Zhao et al. 2021). In addition, the structure and color of amalgam change with the change of temperature and Au/Hg ratio (Tao et al. 2022). Ancient gilding technology exploited these unique traits of mercury and Au-Hg amalgam (Anheuser 1997). Au-Hg amalgam is easier to spread evenly on the surface of decorated objects, facilitating the gilding process and leaving a thin gold film, which also greatly reduced gold usage (Ingo et al. 2013). Compared with other gilding processes, for instance with oil mordant gilding or bole gilding, the gold film of fire gilding performs relatively more durable (Giumlia-Mair 2020). Thus, fire gilding is also well known as the mercury gilding process (Laskaris et al. 2020). At present, based on the literature research and analysis of unearthed cultural relics, the research on ancient Chinese gilding technology is mainly devoted to the textual analysis of the process and determination of gilded products (Masi et al. 2016). During the gilding process, Au-Hg amalgam is first coated on the surface of the base metal, and then, mercury is evaporated through the heating process, forming a gold film on the base metal surface (Margreiter et al. 2016). Hence, several micro-scale gold particles and countless tiny holes are formed on the gold film due to the evaporation of mercury during the heating process. Moreover, owing to the solid-solution characteristics of the Au-Hg system, mercury cannot be completely removed, and a small and variable amount of mercury remains and forms an alloy with gold (Kobiela et al. 2003). Thus, the granular structure and residual mercury are the unique technical characteristics of mercury gilding, which can be employed to distinguish it from other gold decoration processes (Cesareon 2019).

In recent years, more theories of modern materials have been introduced for cultural relics research (Ingo et al. 2013; Drayman-Weissern 2000). Therefore, the study of unearthed cultural relics is no longer limited to the morphological observations or compositional analysis of the golden surface (Ingo et al. 2007). Instead, it goes deep into the interior of the cultural relics to study the compositional distribution and structural characteristics of the cross-section and the interface between the gold layer and the substrate (Ottenwelter et al. 2020), revealing the forming mechanism of the gold layer during the gilding process (Tan et al. 2019). It is worth mentioning that the heating causes phase change of Au-Hg amalgam during the gilding process, thereby forming a gold layer (Jin et al. 2017). Hence, the range of heating temperature is preliminarily defined according to the Au-Hg phase diagram. In general, the gilding process is carried out at low temperatures, and the gold layer is formed due to the solid-phase reaction of gold and mercury rather than the melting process (Mello et al. 2021). In addition, the bidirectional diffusion of metallic atoms between the gold layer and substrate during the heating process is a unique feature of the gilding process (Bayley and Russel 2008). In particular, excess mercury in Ag-Hg amalgam and silver diffused mutually during the gilding of silver substrate, thereby enhancing the adhesion between the gold layer and silver, as well as increasing the attachment of the gold layer to the surface of utensils (Darque-Ceretti 2011). Therefore, research on the formation mechanism of the gold layer and the bonding mechanism between the gold layer and substrate is conducive to the protection, replication, and inheritance of the traditional technology, which is an important aspect of the ancient gilding technology.

One should note that the research on forming mechanism of the gold layer and the bonding mechanism between the gold layer and substrate in ancient gilding technology is quite nascent. Therefore, more attention should be paid to the surface phase composition, cross-sectional microstructure, and compositional distribution, which can expand the characteristic information of the gilding process, provide useful insights into the temperature-dependent changes of Au-Hg amalgam during the forming process, define the range of heating temperature in ancient technology, and facilitate the replication of traditional gilding process. In addition, a comprehensive study of the microstructural changes in the interface between the gold layer and substrate during the gilding process can explain the bonding mechanism at the atomic scale and summarize the technical characteristics of the surface and interface of ancient gilded products, further elaborating the key features of the ancient gilding process.

The Liao (辽) dynasty (907–1125 AD) was established by Khitan nationality at the end of the Tang (唐) dynasty (618–907 AD). Therefore, the science, technology, and traditions of the Liao dynasty are significantly influenced by the Tang culture (Zhao and Kang 2008; Shi 2020). As one of the most successful methods for ancient artisans to explore the effective use of precious and scarce resources, mercury gilding was fully developed in ancient China and reached its peak between the sixth and tenth centuries (Xiao 2021). In Jun–Dec 2015, two large-sized tombs of the elites of the Liao dynasty, named M1 and M2, were excavated at Xiao Wangli Gou (小王力沟) in Duolun County (多伦县), Inner Mongolia. A well-preserved epitaph unearthed from M2 showed that the occupant was Consort Xiao of Emperor Shengzong (辽圣宗萧贵妃), who was entombed in the 11th year of the Tonghe era (统和时期, 993 AD) (Gai et al. 2016). The large-scale and luxurious decorations of M1 date back to the mid-to-late era of the Liao dynasty, showing that the occupant was an important member of Consort Xiao’s family (Zheng 2012). The cemeteries of high-rank imperial concubine family in the Liao dynasty, including M1 and M2, were rated as the Chinese National Top Ten New Archaeological Discoveries in 2015 because of their high standard and value in terms of providing useful insights into the history of the Liao dynasty (Gai et al. 2016).

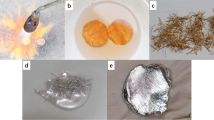

In particular, a group of basically intact burial utensils is unearthed in M2, including a gilding silver high-winged crown and a pair of gilding silver high boots (Fig. 1). The crown overall gilded and decorated with hollow-out cloud patterns is composed of a cap tube and two symmetrical cap wings (Fig. 1a and b). The diameter of the crown is 15 cm, the height of the cap tube is 28.5 cm, and the height and width of the cap wings are 36 cm and 16–21.5 cm, respectively. The front of the tube and both sides of the cap wings are carved with a pair of phoenix patterns flying upward with a Ganoderma-shaped crown, and the surrounding is decorated with hollow-out deformation cloud patterns (Fig. 1e). The pair of high silver boots is made of silver leaves with the thickness of only 0.4 mm, one of which is basically intact, and the other is seriously damaged (Fig. 1c and d). The maximum height, length, and width of the high boots are 42 cm, 27 cm, and 14 cm, respectively. Each boot consists of three parts, namely, the bootleg, the boot top, and the boot sole, which are hammered of silver leaves and then sewed together with fine silver wires. The boot top is decorated with hollowed-out deformation cloud patterns as well as a single gilded phoenix pattern on the left and right sides, respectively. And the bootleg with a gilded edge is decorated with a pair of gilded phoenix patterns (Fig. 1f). The crown and boots made of precious metal are the important burial utensils of large noble tombs in the middle of the Liao dynasty. The metal crowns of the Khitan nationality mainly include gold crowns and gilded silver crowns, of which gold crowns are the most noble crowns used by emperors. The gilded silver crowns are used by nobles. Unfortunately, many imperial tombs of the Liao dynasty are destroyed, and the Tomb of Princess Chen (陈国) discovered in 1986 is only second to the imperial tombs. Therefore, most of the cultural relics unearthed from the Princess Tomb are the unique example of the Liao dynasty culture (Sun and Zhang 1987), and the gilding silver crown with phoenix patterns becomes the highest level of crown of the Liao dynasty unearthed so far (Lu and Wang 2010). Among the tombs of the Liao dynasty reported so far, the tomb of Consort Xiao’s family is not only in the same historical period as the tomb of Princess Chen (Quan 2015), but also the identity of the tomb owners is similar. Moreover, compared with the single-winged crown in the tomb of the princess of Chen, the two-winged crown unearthed in M2 clearly shows that its burial utensil is more valuable and informative combination is more valuable and informative (Quan 2015). Thus, these items from M2 become the highest level of burial utensils found in the Khitan Aristocratic Tombs (Zhang and Zhao 2000). Obviously, silver gilding products are the most representative cultural relics to study the gilding process during a given era (Lee 2013). The detailed analysis of the gilding layer provides useful insights into the formation mechanism of the gold layer, as well as the bonding mechanism between the gold layer and substrate.

Herein, the surface composition and microstructural characteristics of the golden surface and the unique multilayered structure on the cross-section of the gilded silver products are obtained using scanning electron microscopy (SEM), X-ray diffraction (XRD), and X-ray photoelectron spectroscopy (XPS). The research results explain the formation mechanism of the gold layer during the silver gilding technology, as well as provide useful information about the atomic-scale bonding mechanism between the gold film and substrate.

Materials

The analysis objects of this study are selected from the scattered fragments of the crown and boots that fell off when they were unearthed to avoid damaging the valuable cultural relics. In order to obtain accurate information of the surface and interface of gilding products, not only the complete gold layer but also the flat surface become the important conditions for selecting the analysis object. Moreover, the substrate must be free of corrosion and firmly bonded with the gold layer, and their interface should be kept intact, making it more difficult to select the appropriate analysis object. The scattered fragments are poorly preserved, and only two objects that are most suitable and representative for research are selected from so many fragments and labeled YG and YX, respectively (Their positions on the crown and boot are shown in Fig. 2a and b, respectively). Fortunately, the gold layers of YG and YX are flat and firmly bonded with the substrates, and the interface is well preserved, which are enough to be selected as the typical samples for us to study the interface characteristics of gilded products. YG measures a maximum of 8 mm in length and a maximum of 5 mm in width, and YX measures a maximum of 8 mm in length and a maximum of 10 mm in width.

The composition and phase composition of the gold layer on the surface of the crown and boots can be directly obtained by using non-destructive technology to analyze YG and YX. However, to explore the cross-sectional composition and structural characteristics, the cross-sectional samples are made according to the following steps. The fragments (2 mm*2 mm) are first cut from YG and YX, then inlaid in the embedding resins (prepared of Buehler epoxy resin and Buehler epoxy hardener), ground using abrasive papers from 300 to 1200 grit, polished using a high-speed polishing machine (Buehler AutoMet 250) and a polishing agent with a diameter of ~ 2.5 μm. The obtained samples with a smooth surface are washed with ultra-pure water to remove the polishing agent and dried thoroughly. Finally, the cross-sectional samples are obtained, which are labeled YGC and YXC, respectively.

Methods

Microstructural and compositional analyses

The samples were examined and photographed using an SEM (ZEISS EVO MA25), equipped with an Oxford X-max 20 EDS console to obtain secondary electron (SEM) images, backscattered electron (BSE) images, and compositional information. SEM–EDS was operated under an accelerating voltage of 20 kV, where the EDS working distance was approximately 8–9 mm. The ESD data was obtained by standardless analysis method according to Chinese national standard GB/T 17,359–2012, and the industrial copper standard sample was used for calibration and optimization. Each micro-area was analyzed at least three times, and the elemental results detected were averaged and normalized.

Phase analysis

X-ray diffraction (XRD, Kratos XRD-7000, Cu-Kα radiations) was used to identify the metals and metallic compounds. The X-ray generator was equipped with a monochromator, where a capillary attachment was used to enhance the signal. XRD patterns were collected in the 2θ range of 15° to 130° with a scan speed of 8°/min. The JADE 6.0 software was used to compare each diffraction pattern with the reference patterns in the ICDD PDF2–2004 database.

The study of the surface chemical features and bonding configuration of samples had been performed using the X-ray photoelectron spectrometer (XPS, Kratos, Axis Supra). CASAXPS software was used to fit the binding energy data, and the Gauss–Lorentz method was used to fit XPS spectra. For the XPS spectra acquisition, an electron energy semispherical analyzer was fixed at 20 eV constant pass energy, ensuring a constant energy resolution over the entire measured range and achieving an energy resolution for Ag 3d5/2 in Ar+ sputtered metal of 1.0 eV. The scale of the binding energy (BE) was calibrated by measuring the value of the C 1 s photoemission signal (BE = 285.0 eV) of the ubiquitous carbon and Au 4f7/2 signal (BE = 84.0 eV) from argon ion-cleaned Au 99.99%. The accuracy of the BE scale was ± 0.1 eV.

Results

Compositional and microstructural characteristics

In the SEM images of YG and YX, unidirectional scratches with a uniform thickness can be clearly observed in most of the flat areas (Fig. 3a and b), whereas abundant fine particles with a diameter of around 2 μm are found in the groove area around the decoration (Fig. 3b, c, and d). The silvery surface of the sample was mainly composed of Ag with around 2 wt. % Cl. The silver crown and boots were made of pure silver, and the corrosion products were formed on the surface of cultural relics under the influence of long-term environmental factors (Table 1). The golden surface was composed of Au and Hg, as well as a small amount of Ag came from the substrate diffusion. The presence of Hg and granular morphology on the golden surface clearly reveals that the technique used to coat the hat crown and boots was mercury gilding (Yao and Zhao 2022). Owing to the evaporation of mercury during the gilding process, the resulting structure of the gold film was granular and porous. Even if the ancient craftsmen gently flattened the porous film to create a smooth and shiny surface similar to gold, micro-pores and fine particles might remain in the gold film, especially in grooves (Jin et al. 2017).

Interfacial structure of the gold layer and substrate

In high-magnification SEM images of fresh-fracture of YG, several structural layers with different characteristics were found between the surface and substrate of the gilded cultural relics (Fig. 4). The top layer in the cross-section was the gold layer, whose surface was relatively flat after polishing, whereas a layer with granular structure was observed beneath the surface. Moreover, a fine porous layer was found under the granular structure, where the porous structure was extended to the substrate. Furthermore, the detailed microstructural information and compositional characteristics of the multilayered structure were intuitively shown by the cross-sectional analysis after embedding and polishing. The light–dark contrast of the BSD image was different in different areas of the cross-section of YGC (Fig. 5). According to EDS results, the main components of the silver gilding sample were Au, Ag, and Hg (Table 2), originating from the difference in the proportion of these elements. The top cross-sectional layer of the YGC sample was a grey-white area and mainly composed of Au (90 wt. %) and Hg (8 wt. %), as well as a small amount of Ag (2 wt. %). Obviously, this area was the gold layer of the gilding sample. Moreover, several pores were observed between gold particles. In the light grey area under the gold layer, compared with the composition of the gold layer, Au content decreased sharply to 1.4 wt. %, whereas Ag content increased significantly, and Hg content increased slightly. The main components were Ag (71 wt. %) and Hg (27.6 wt. %). The light grey area was named as the transition layer to distinguish it from the gold layer because it is a transition region between the grey-white area and the grey area. The lower layer was a light gray porous structure, where Ag content continued to increase to 93.6 wt. %, while Hg content dropped to about 4.4 wt. %. The gray area at the bottom layer was mainly composed of Ag and a small amount of Cu, corresponding to the substrate. The changing trend of Au, Ag, and Hg contents can be more intuitively reflected in the relative concentration curve of different elements (Fig. 6). Au content was highest in the gold layer and decreased towards the substrate. Ag mainly existed in the substrate and diffused to the surface of the gold layer. Hg content initially increased from the gold layer to the substrate, followed by a decrease. Thus, the transition and porous layers were formed with silver and mercury as constituent elements. The structural layers with different elements and morphologies were also observed in the cross-sectional SEM images of the YXC sample (Fig. 7 and Table 3). Therefore, according to different compositional distribution and structural characteristics, the cross-section of silver gilding products can be divided into four layers from the surface to the substrate: gold layer, transition layer, porous layer, and substrate.

Phase composition

Furthermore, XPS was carried out to further analyze the elements on the surface of the gold layer and possible interactions between Au and Hg. The interactions between Au and Hg can be seen in the XPS spectra of the YG sample (Fig. 8). After peak fitting and C 1 s correction, the 4f7/2 and 4f5/2 peaks of Au appeared at 84.2 eV and 87.9 eV, respectively. These peak positions are higher than the standard 84.1 eV and 87 eV, which can be attributed to the lattice disorder of Au caused by the residual Hg in the gold film, confirming the presence of Au-Hg compounds in the gold layer besides the element gold (Singh and Singh 2019). Moreover, the peaks at 104.4 eV and 100.1 eV correspond to Hg 4f5/2 and Hg 4f7/2, respectively, verifying the presence of Hg in the gold layer (Ma et al. 2019; Süzer 2000). The interactions between Au and Hg can also be seen in the XPS spectra of the YX sample (Fig. 9). In addition, compared with the zero valent metal, the peaks of Ag (Ag 3d3/2 and Ag 3d5/2) and Cl (Cl 2p1/2 and Cl 2p3/2) in the YG samples changed due to the formation of silver chloride. Furthermore, XRD patterns of the golden surface of YG and YX demonstrate the structure of Au-Hg compound and Ag-based corrosion products in the gold layer (Chen et al. 2015). The characteristic gold peaks are observed at 2θ = 37.8°, 43.9°, 63.7°, 76.8°, and 80.7°, corresponding to (111), (200), (220), (311), and (222) planes of Au5Hg, respectively (Fig. 10). The positions of the characteristic peaks correspond to the standard map, but the peak shape is widened, and the intensity is slightly altered due to the superposition of characteristic peaks on Au, i.e., (111), (200) (220), (311), and (222) planes. Moreover, Au5Hg and Au were also found in the YX sample (Fig. 11). Consistent with XPS results, XRD results of some regions also confirmed the presence of the corrosion product, i.e., silver chloride.

Discussion

Temperature of the heating process and formation process of the gold layer

The use of mercury in the gilding process was the biggest difference from all other gold decoration processes (Gard et al. 2019). Especially in silver gilding products, due to the formation of Au-Hg and Ag-Hg systems during the gilding process, mercury became an important factor in the forming mechanism of the gold layer and bonding between the gold layer and substrate (Deng et al. 2013). According to previous reports, scholars have been trying to study the formation mechanism of the gold layer which is determined by the heating temperature of the gilding process by analyzing the phase composition, but have not reached a consistent conclusion. In the early research, α-Au and δ-Au3Hg phases were found on the gold layer when conducting the phase analysis of the surface of gilded cultural relics. α-Au was believed to be formed by solidification at high temperatures (> 419 ℃) (Lim and Kang 1992). However, at T < 419 ℃, the α′ phase was formed through a peritectic reaction. It has been speculated that the composition difference was significant between the solidus and liquidus of the coexisting regions of the liquid phase and α-Au phase, inhibiting the peritectic reaction and forming ζ-Au3Hg phase in the non-equilibrium state (Okamoto and Massalski 1989). In addition, the EMPA analysis of gilded copper samples from the third century BC to the first century BC revealed that the residual mercury content was 9–17 wt. %, which is within the solid-solution region of the phase diagram (Bunker et al. 1993). Therefore, in combination with the phase diagram, the scholars believed that the gold layer of gilding products was solidified and formed again after the gold amalgam was heated and melted at T > 500 ℃.

However, in later research, some scholars argued that the heating process was carried out in a low the temperature range. They believed that the key point of the ancient gilding process was that the decorative layer was firmly attached to the substrate and obtained a gold-like color. Therefore, the metalsmith must be careful to avoid overheating because of copper’s tendency to oxidize in air at high temperatures. Owing to the porosity of gold amalgam, a black-colored oxide layer of copper was also formed beneath the gold, the thickness of which increased with increasing temperature and heating time. This layer eventually caused the flaking of gold film (Anheuser 1997). In the case of silver, which could be brought to red heat in air without oxidizing, the temperature was limited by the rate of interdiffusion between the gold layer and silver substrate. If silver was overheated, the gold would discolor or even disappear into the substrate altogether; hence, the firing temperature could not be excessively high (Guo and Tan 2012). Therefore, after the gold amalgam was coated on the substrate, the heating process was carried out in the temperature range of 250–300 ℃, which is much lower than the boiling point of mercury (357 ℃). Also, when the color of gold amalgam changed from gray to dark yellow, the heating was stopped, and polishing was carried out.

The phases of Au5Hg found on the golden surface of YG and YX samples provide new inspiration for the study of the heating temperature of gilded products. During the actual gilding process, the initial gold/mercury ratio of amalgam ranges from 1:5 to 1:6. Combined with the phase diagram, in addition to the elemental mercury, there were various gold mercury compounds with a high mercury ratio in the system (Kobiela et al. 2003; Chudnenko. and Pal’yanova 2013). Moreover, Au-Hg system became a unique open system due to the evaporation of mercury and Au-Hg compounds gradually decomposed with increasing temperature during the gilding process. The compound with the highest mercury content, i.e., AuHg2, was stable up to 310 ℃, and it decomposed to form Au2Hg and a liquid phase at T > 310 ℃. Moreover, Au2Hg continued to decompose to form Au3Hg with the increase of temperature. In the temperature range of 388–419 ℃, several gold-mercury compounds existed in the system, such as Au4Hg, Au5Hg, and Au13Hg (Okamoto and Massalski 1989; Crede et al. 2020) Some of these phases are stable only at certain pressures, and some may exist as metastable phases. Once the temperature exceeded 419 ℃, there would be only Au-Hg solid-solution in the system (Nishio-Hamane et al. 2018). The phases of Au5Hg and Au were found in the gold layer on the golden surface of YG and YX samples. Combined with the Au-Hg phase diagram (Fig. 12), the temperature of this open Au-Hg system was at least higher than 388 ℃ during the heating process, but it did not reach the melting point of 419 ℃. The temperature variation of the gilding products from the Liao dynasty was controlled within 30 ℃, indicating that the temperature control of gilding technology reached a high level in this period. In addition, the flat golden-yellow surface and uniform gold layer thickness revealed that the quality control of amalgam coating and polishing program was extremely strict. It could be seen that the gilding technology, which originated in the Spring and Autumn period and the War States period, has matured in the Liao dynasty.

Bonding between gold layer and substrate

The Ag-Hg system in silver gilding products played another important role in the gilding process. A unique multilayered structure, including a gold layer, transition layer, and pore layer, was observed in the cross-sections of the crown and boots, where the content of Hg in the transition layer reached up to 30 wt. %. The Ag-Hg system firmly combined the gold layer of silver gilding products with the substrate through the transition layer under the influence of Hg and Ag diffusion (Molnár and Beke 2014). There are two possible diffusion mechanisms (Pinnel 1979). First, the classical bulk or lattice diffusion involves vacancy-assisted atomic exchange, where temperatures near the melting point are required to complete the reaction in a reasonable time. Second, rapid diffusion may occur along defect paths even at low temperatures in many systems. One should note that defects, such as grain boundaries and dislocations, are common in metals and act as rapid transportation channels through a metallic layer, favoriting the rapid diffusion mechanism (Qurat-ul-ain et al. 2021). The atomic diffusion process of amalgam and silver substrate during the processing of silver gilding products is schematically illustrated in Fig. 13. During the gilding process, silver gray amalgam was first coated on the substrate (Fig. 13a). Due to the higher solid solubility of Ag-Hg system than Au-Hg system, reaching 50 wt. % at room temperature (Chudnenkoa and Pa’yanovab 2013), the excessive liquid mercury in the gold amalgam rapidly diffused to the silver surface, thereby forming a diffusion layer with a high Hg content on the substrate surface (Bayley and Russel 2008). Then, owing to the low boiling point of mercury, the subsequent heating process during gilding promoted the sublimation of a large number of mercury atoms in the amalgam and removed Hg from the system. In this process, the amalgam became an intermetallic compound with a high Au content, and its color changed from silver gray to light yellow (Laskaris et al. 2020). At the same time, the increase in temperature also promoted the diffusion of silver atoms near the amalgam towards the amalgam with higher Hg content, leaving atomic vacancies in the diffusion layer and playing a major role in fixing some mercury atoms (Fig. 13b) (Molnár and Beke 2014). The heating process continued at an appropriate temperature until the amalgam obtained the desired golden color. Finally, after the evaporation of a large number of mercury atoms, a gold layer was obtained with a granular morphology and porous structure (Weiszburg et al. 2017). Under the gold layer, a transition layer consisting of Hg and Ag was formed. Moreover, the diffusion of silver atoms left a large number of atomic vacancies in the substrate, thereby forming a porous layer structure between the transition layer and substrate (Fig. 13c) (Kim and Yu 2010). After the final polishing step, the gilding products finally obtained a relatively flat gold layer; however, the pore structure, transition layer, and porous layer were preserved forever (Fig. 13d).

In conclusion, it can be seen from the atomic diffusion phenomenon during the gilding process that mercury plays a crucial role in bonding of the gold layer and substrate in silver gilded products. Obviously, the bonding mechanism of gold layer and substrate can be explained by the diffusion of Ag-Hg system at the atomic scale: First, the spontaneous diffusion of liquid Hg to the substrate at room temperature and, then, vacancy-assisted diffusion of silver atoms to mercury during heating. In addition, the bonding mechanism at the atomic scale is also reflected in the cross-sectional microstructure, which is another typical technical feature of silver gilding process. One should note that the cross-sectional microstructure contains a porous layer and a transition layer structure with mercury and silver as main components.

Conclusions

In summary, SEM–EDS, XRD, and XPS have been employed to comprehensively analyze the microstructure, structure and composition of the golden surface and cross-section of silver crown and boots from the Liao dynasty. The presence of mercury and unique gold granular morphology on the golden surface clearly revealed that mercury gilding was used to coat the cultural relics. In addition, the intermetallic compound, i.e., Au5Hg, was found for the first time on the gold layer in this study, and according to the Au-Hg phase diagram, the heating temperature during the process was supposed to be 388–419 ℃. Therefore, the formation mechanism of gold layer was the transformation of solid solution in amalgam at room temperature into an intermetallic compound during the heating process. Moreover, the atomic diffusion of Ag-Hg system formed a unique multilayered structure on the cross-section of silver gilding cultural relics during the heating process, including porous gold layer, transition layer, and porous layer. The formation process of the multilayered structure also explained the bonding mechanism between the gold layer and substrate during the silver gilding process. First, when Au-Hg amalgam spread on the substrate surface, excessive liquid mercury diffused to the substrate. Then, silver atoms diffused to the gold layer and fixed some mercury atoms during the heating process, forming the transition layer. Thus, the interstitial diffusion of mercury atoms at room temperature and vacancy-assisted diffusion of silver atoms during heating in the Ag-Hg system facilitated the bonding between the gold layer and substrate.

However, it must be admitted that due to the limitation of the number of samples, not all the technical features of this group of gilded products were obtained. Fortunately, the commonness of the two samples revealed the unique multilayered structure and compositional distribution of the cross-section of the silver-gilded cultural relics and proved that mercury played a crucial role in both formation of gold layer and bonding between the gold layer and substrate.

Data availability

The data and materials used during the study are available from the corresponding author on reasonable requests. All data produced in this study are included in the paper.

Code availability

Not applicable.

Change history

04 March 2023

A Correction to this paper has been published: https://doi.org/10.1007/s12520-023-01740-5

Abbreviations

- SEM-EDS:

-

Scanning electron microscope with energy dispersive spectrometer

- BSE:

-

Backscattered electron

- Hg:

-

Mercury

- Au:

-

Gold

- Ag:

-

Silver

- Cu:

-

Copper

- Cl:

-

Chlorine

References

Anheuser K (1997) The practice and characterization of historic fire gilding techniques. Archaeotechnology 49(11):58–62. https://doi.org/10.1007/s11837-997-0015-6

Bayley J, Russel A (2008) Making gold-mercury amalgam: the evidence for gilding from Southampton. Antiqu J 88:37–42. https://doi.org/10.1017/S0003581500001335

Cesareon R (2019) Gold, gildings, and tumbaga from the Moche tomb of the Lady of Cao: an EDXRF test for the internal ratio method. X-Ray Spectrom 48(3):202–207. https://doi.org/10.1002/xrs.3021

Chen F, Yang Q, Niu C et al (2015) (2015) Plasmonic photocatalyst Ag@AgCl/ZnSn(OH)6: synthesis, characterization and enhanced visible-light photocatalytic activity in the decomposition of dyes and phenol. RSC Adv 5:63152–63164. https://doi.org/10.1039/C5RA10480G

Chudnenko K, Pal’yanova G (2013) Thermodynamic properties of Au-Hg binary solid solution. Thermochim Acta 566:175–180. https://doi.org/10.1016/j.tca.2013.05.041

Chudnenkoa K, Pa’yanovab G (2013) Thermodynamic properties of Ag-Au-Hg solid solutions. Thermochim Acta 572:65–70. https://doi.org/10.1016/j.tca.2013.08.024

Crede L, Evans K, Rempel K et al (2020) Revisiting hydrocarbon phase mobilization of Au in the Au–Hg McLaughlin Mine, Geysers/Clear Lake area. California. Ore Geology Reviews 117:103218. https://doi.org/10.1016/j.oregeorev.2019.103218

Darque-Ceretti E (2011) Felder E and Aucouturier M (2011) Foil and leaf gilding on cultural artifacts; forming and adhesion. Revista Matéria 16(1):540–559. https://doi.org/10.1590/S1517-70762011000100002

Drayman-Weissern T (2000) Gilded Metals: history, technology, and conservation. Archetype Publications in Association with the American Institute for Conservation of History and Artistic Works 2000:116

Gard F, Daizo M, Santos D et al (2019) Application of surface science techniques to study a gilded Egyptian funerary mask: a multi-analytical approach. Surf Interface Anal 51(10):1001–1017. https://doi.org/10.1002/sia.6685

Giumlia-Mair A (2020) Plating and surface treatments on ancient metalwork. Advances in Archaeomaterials 1(1):1–26. https://doi.org/10.1016/j.aia.2020.10.001

Guo T, Tan Y (2012) Formation of one-dimensional Ag-Au solid solution colloids with Au nanorods as seeds, their alloying mechanisms, and surface plasmon resonances. Nanoscale 5(2):561–569. https://doi.org/10.1039/C2NR32862C

Ingo G, Guida G, Angelini E et al (2013) Ancient mercury-based plating methods: combined use of surface analytical techniques for the study of manufacturing process and degradation phenomena. Account of Chemical Research 46(11):2365–2375. https://doi.org/10.1021/ar300232e

Jett P (1993) A study of the gilding of Chinese buddhist bronzes. Metal Plating Patination 1993:193–200. https://doi.org/10.1016/B978-0-7506-1611-9.50021-2

Jin P, Ruan F, Yang X et al (2017) Microstructural and componential characterization of the plating technology on Chinese Han Dynasty bronze fragments. Archaeometry 59(2):274–286. https://doi.org/10.1111/arcm.12246

Kim S, Yu J (2010) Effects of Ag on the Kirkendall void formation of Sn-xAg/Cu solder joints. J Appl Phys 108(8):765. https://doi.org/10.1063/1.3488629

Laskaris N, Varalis I, Tsodoulos C et al (2020) (2020) Evidence of Au-Hg gilding process in post byzantine ecclesiastical silverwres (Chalices) of easterrn Thessaly by PXRF. Mediterranean Archaeology Archaeometry 20(1):189–203. https://doi.org/10.5281/zenodo.3605677

Lee C (2013) An analysis of the distinguishing features of gold and silver metalworking in the Liao dynasty as seen from archaeological materials. Journal of History of Fu Jen Catholic University 30:1–55. https://doi.org/10.1016/j.ajodo.2007.08.035

Leusch V, Armbruster B, Pernicka E et al (2015) On the invention of gold metallurgy: the gold objects from the Varna I Cemetery (Bulgaria)-technological consequence and inventive creativity. Camb Archaeol J 25(01):353–376. https://doi.org/10.1017/S0959774314001140

Lins P, Oddy A (1975) The Origins of Mercury Gilding 2(4):365–373. https://doi.org/10.1016/0305-4403(75)90007-2

Ma C, Ma Y, Sun Y et al (2019) Colorimetric determination of Hg2+ in environmental water based on the Hg2+-stimulated peroxidase mimetic activity of MoS2-Au composites. Journal of Colloid Interface Science 537:554–561. https://doi.org/10.1016/j.jcis.2018.11.069

Masi G, Chiavari C, Avila J et al (2016) Corrosion investigation of fire-gilded bronze involving high surface resolution spectroscopic imaging. Appl Surf Sci 366:317–327. https://doi.org/10.1016/j.apsusc.2016.01.101

Mello E, Paola E, Marra G et al (2021) Advances in materials and technological characterization of Lorenzo Ghiberti’s Gates of Paradise. The European Physical Journal plus 136(8):1–11. https://doi.org/10.1140/epjp/s13360-021-01851-9

Nishio-Hamane D, Tanaka T, Minakawa T (2018) Aurihydrargyrumite, a natural Au6Hg5 phase from Japan. Minerals 8(9):415–423. https://doi.org/10.3390/min8090415

Oddy A (1991) Gilding: an outline of the technological history of the plating of gold on to silver or copper in the Old World. Endeavour. https://doi.org/10.1016/0160-9327(91)90085-P

Oddy A (1993) Gilding of metals in the old world[J]. Metal Plating Patination 3:171–181. https://doi.org/10.1016/B978-0-7506-1611-9.50019-4

Okamoto H, Massalski T (1989) (1989) The Au-Hg (gold-mercury) system. Bulletin of Alloy Phase Diagrams 10(1):50–58. https://doi.org/10.1007/BF02882176

Ottenwelter E, Barčáková L, Josse C et al (2020) Technological characterisation of early Medieval gilded copper hollow pendants (gombiky), from Mikulčice (Moravia) and Prague Castle (Bohemia). Archaeol Anthropol Sci 12(7):1–22. https://doi.org/10.1007/s12520-020-01084-4

Pinnel M (1979) Diffusion-related behaviour of gold in thin film systems. Gold Bulletin 12:62–71. https://doi.org/10.1007/BF03216542

Qurat-ul-ain K, Javid M, Rafique M et al (2021) Synthesis and mechanical properties of dental amalgam. Materials Today: Proceedings 47(1):s33–s37. https://doi.org/10.1016/j.matpr.2020.04.672

Süzer S (2000) XPS investigation of X-ray-induced reduction of metal ions. Appl Spectrosc 54(11):1716–1718. https://doi.org/10.1366/000370200194877

Tan P, Yang J, Zheng Y et al (2019) Copper granulation: scientific analysis on the ornaments from the coronet of Lady Pei of the early Tang Dynasty (618–712 A.D.) in Xi’an, Shaanxi. China Archaeological and Anthropological Sciences 11:6603–6613. https://doi.org/10.1007/s12520-019-00929-x

Weiszburg T, Gherdan K, Ratter K et al (2017) Medieval gilding technology of historical metal threads revealed by electron optical and micro-Raman spectroscopic study of focused ion beam-milled cross sections. Anal Chem 89(20):10753–10760. https://doi.org/10.1021/acs.analchem.7b01917

Bunker E et al. (1993) Outils et ateliers d’orfevres des temps anciens, Antiquites Nationales Memoire 2, ed. Christiane Eluere (St. Germain-en-Laye: Musee des Antiquites Nationales, 55–66.

Deng L, Ouyang X, Jin J, et al. (2013) Exploiting the higher specificity of silver amalgamation: selective detection of mercury (II) by forming Ag/Hg amalgam. Analytical Chemistry: 8594–8600. https://doi.org/10.1021/ac401408m

Gai Z, Li Q, Feng J, et al. (2016) Tombs of Liao Dynasty Aristocrats in Xiaowangligou, Duolun County, Inner Mongolia[J]. Archaeology, (10):55–80. 盖之庸, 李权, 冯吉祥等.内蒙古多伦县小王力沟辽代贵族墓葬. 文物, 2016.

Gao X (2009) A research of gold-plating technique- starting with gold-plated bronzed wares found in Luoyang[J]. Journal of Luoyang Normal university, (06): 23–26. 高西省. 鎏金工艺研究-从洛阳发现的战国鎏金铜器谈起. 洛阳师范学院学报, 2009. https://doi.org/10.16594/j.cnki.41-1302/g4.2009.06.028

Ingo G, Padeletti G, Caro T, et al. (2007) Microchemical investigation of ancient silver and gold plated objects: coating techniques and degradation mechanisms. Strategies for Saving our Cultural Heritage, 2007: 9–13. http://www.afir.org.ro/sica/ref/2008_Ingo.pdf

Kobiela T, Nowakowski B and Duś R (2003) The influence of gas phase composition on the process of Au-Hg amalgam formation. Applied Surface Science, 78–89. https://doi.org/10.1016/S0169-4332(02)01190-X

Lim S and Kang S (1992) A study on the gold film coated on the ancient gilt bronze. Journal of the Korean Conservation Science for Cultural Properties, 1(1): 60–79. https://koreascience.kr/article/JAKO199217033618457.pdf

Liu Y, Yang J and Tan P (2019) Some new thoughts about the technology of “Cuojinyin”. Science of Conservation and Archaeology, 031(004): 75–86. 刘艳, 杨军昌, 谭盼盼. "错金银"新论. 文物保护与考古科学, 2019. https://doi.org/10.16334/j.cnki.cn31-1652/k.2019.04.010

Liu Y, Li R, Yang J, Liu R, et al. (2021) China and the steppe: technological study of precious metalwork from Xigoupan Tomb 2 (4th-3rd c. BCE) in the Ordos region, Inner Mongolia. Heritage Science, 9(1). https://doi.org/10.1186/s40494-021-00520-5

Lu F and Wang J (2010) Study on the style of Khitan golden crowns. Sichuan Cultural Relics, 5: 50–53. 卢昉, 王江鹏. 契丹金冠型式研究. 四川文物, 2010.

Margreiter R, Eberhardt K, Niemeyer B, et al. (2016) Investigation on fire gilding using XRF and NAA, in NRC-9. Helsinki, Finland.

Molnár G and Beke D (2014) Investigation of diffusion and solid-state reaction in thin film systems. ACTA Physica Debrecina. http://www.phys.unideb.hu/apd/sites/default/files/content/2014/molnargabor.pdf

Quan Y (2015) Silver boots of Princess Chen. West Leather, (17): 60–61. 全岳. 陈国公主的银靴. 西部皮革, 2015.

Shi C (2020) Re study of the family history of the tomb owner of the Liao Dynasty’s imperial concubine Xiaowangligou in Duolun County, Inner Mongolia. Northern Cultural Relic, (5): 86–91. 史风春. 内蒙古多伦县小王力沟辽代贵妃墓墓主家世再考. 北方文物, 2020. https://doi.org/10.16422/j.cnki.1001-0483.2020.05.009

Singh V and Singh S (2019) Mercury-amalgam gilding in Nepal: a study of traditional material and technique. in METAL 2016-Interim Meeting of the ICOM-CC Metals Working Group September 26–30, New Delhi India.

Sun J and Zhang Y (1987) A brief report on the excavation of the co-burial tomb of the princess’s son-in-law of Chen State of Liao Dynasty. Cultural Relics, (11): 4–24+97–106. 孙建华, 张郁. 辽陈国公主驸马合葬墓发掘简报.文物, 1987.

Tao J, Chen S, Kouadio F, et al. (2022) Tailoring dual-functional gold nanoplasmonic rods for colorimetric and SERS detection of mercury species in complex matrices. Chemical Engineering Journal: 139026. https://doi.org/10.1016/j.cej.2022.139026

Xiao H (2021) A probe into the manufacturing technology of gold and silver wares in Liao Dynasty. Journal of Chifeng University (Soc. Sci), 42(1): 68–72. 肖红艳. 辽代金银器制作工艺探析. 赤峰学院学报 (汉文哲学社会科学版) , 2021. https://doi.org/10.13398/j.cnki.issn1673-2596.2021.01.017

Yao Z and Zhao R (2022) Viewing the metalworking craft of the Tang Dynasty from two gold and silver objects unearthed from the Tang Tomb at the site of Baofeng Xiaodian. (8): 88–96. 姚智辉, 赵瑞. 从宝丰小店唐墓出土两件金银器看唐代金工工艺. 文物, 2022. https://doi.org/10.13619/j.cnki.cn11-1532/k.2022.08.001

Yao Z (2019) Re Understanding of ancient gold inlay and gilding techniques. Huaxia Archaeology, 2019(5): 113–119. 姚智辉. 对古代错金、鎏金工艺的再认识. 华夏考古, 2019. https://doi.org/10.16143/j.cnki.1001-9928.2019.05.011

Zhang J and Zhao A (2000) The evolution and craft of the ornaments of gold and silver wares in Liao Dynasty. Northern Cultural Relics, (1): 39–45.张景明, 赵爱军. 辽代金银器的器形纹饰演变及工艺. 北方文物, 2000. https://doi.org/10.16422/j.cnki.1001-0483.2000.01.009

Zhao R and Kang Y (2008) Influence of gold and silver technology of the Tang Dynasty on the gold and silver wessels in the Liao Dynasty. Journal of InnerMonggolia University (Philosophy & Social Science), 37(5): p. 118–121. 赵瑞廷, 康宇凤. 唐代金银工艺对辽代金银器的影响. 内蒙古师范大学学报 (哲学社会科学版) , 2008.

Zhao J, Liu R and Lv Y (2021) Interviews with elements: “Femme Fatale” mercury[J]. University Chemistry, 36(10): 39–40. 赵劲一, 刘睿, 吕弋. 元素访谈-蛇蝎美人-汞. 大学化学, 2021.

Zheng C (2012) Research on the funeral system of nobility in the Liao Dynasty. Tianjin: Nankai University, 2012: 153–175. 郑承燕. 辽代贵族丧葬制度研究. 2012, 南开大学.

Acknowledgements

We would like to thank the Inner Mongolia Institute of Culture Relics and Archaeology and Duolun Noer Museum for the samples. The authors are grateful to Ms. Xiaojuan Dang and Ms. Juan Ji from the Shaanxi Institute for the Preservation of Cultural Heritage for the support and help on the metallographic investigation and SEM-EDS. Special thanks go to Zhuoyan Tuoba and Lifeng Jiang for suggestions on the manuscript.

Funding

The project is supported by: The Humanities and Social Sciences Foundation of Ministry of Education of China (No. 21YJCZH050). Natural Science Basic Research Program of Shaanxi (Program No. 2021JQ105). Scientific Research Project of Shaanxi History Museum (Program No. GJ2021007). The Fundamental Research Funds for the Central Universities (Social Sciences), Northwestern Polytechnical University (No. D5000210802).

Author information

Authors and Affiliations

Contributions

Yanbing Shao: methodology, validation, investigation, data analyses, writing—original draft, and writing—review and editing.

Xuan Lu, Wenbin Fu, Zhiyong Gai, and Linin Dong: project administration, excavation, and restoration of cultural relics.

Fengrui Jiang: methodology, project administration, and writing—review and editing.

Junchang Yang: methodology and project administration.

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised:

The authors regret that some of the authors in the article do not conform to their affiliations.

The original article has been corrected.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shao, Y., Lu, X., Fu, W. et al. Technical characteristics and coating formation mechanism of gilded silver products unearthed from the Consort Tomb of Emperor Shengzong of the Liao dynasty. Archaeol Anthropol Sci 15, 28 (2023). https://doi.org/10.1007/s12520-023-01725-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-023-01725-4