Abstract

Changes in firing practice have been suggested as representing a revolution in ceramic technology at the beginning of the Bronze Age in Crete. The introduction of kiln structures has been held responsible for such a change, perhaps by newcomers to the island, along with other innovative technologies. However, these hypotheses were often based on limited analytical data and mostly on macroscopic examination. This paper re-examines the suggestion of a transformation in firing technology at the beginning of the Bronze Age by presenting analyses of the rich ceramic assemblage from the site of Phaistos in South-Central Crete, which offers a rare, good stratigraphic sequence from the end of the Final Neolithic into the Early Bronze Age. Here, firing technology is reconstructed by macroscopic examination of colour across vessel breaks, by SEM examination and FT-IR analysis. This allows the reconstruction of temperature ranges and firing rates over the phases considered and a re-assessment of changes in firing technology, revealing a more multi-faceted pattern of change. Finally, changes in firing procedure are contextualised in the overall ceramic operational sequence, revealing a complex, stepped picture of change in ceramic production over the transition from the Final Neolithic.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Firing causes mineralogical and microstructural modification of clay bodies, which results in changes in characteristics such as porosity, resistance to physical and thermal stress, colour and hardness, all of which are key elements for the potter (cf. Rice 1987, pp. 80–109) as well as for the consumer. The type of raw material used, the kind of firing structure, temperature, atmosphere and duration of firing all influence such microstructural and mineralogical changes. While the reconstruction of ancient pyro-technology is a complex procedure, on account of the large number of variables involved, it remains important within archaeological science, because of its implications for our understanding of innovation and technological practice. As Tite (1995) has pointed out, of all the steps of the ceramic manufacturing sequence, firing reconstruction offers the archaeological scientist the allure of producing numerical results in the form of temperatures. The estimation of firing temperature, or better of ‘equivalent firing temperature’ (Teq, cf. Robert 1963), was considered in the past literature the sole purpose of ceramic investigations and was often disconnected from its archaeological significance (cf. Perrinet and Courtois 1983; Edwards and Segnit 1984; Kaiser and Lucius 1989). At times, estimated firing temperatures were also used by archaeologists to distinguish between the use of ‘kilns’ and ‘open-firing’ as a way to measure technological advancement of past societies. Such simplistic approaches led to a reaction based on ethnography. Gosselain (1992) suggested that, rather than firing temperature, the differences in the duration and in the temperature rate are the only variables that allow firing structures to be distinguished, which may not be accessible to archaeologists. Indeed, Livingstone Smith (2001) suggested that there are no thermal parameters which allow us to clearly distinguish between different firing structures. More importantly, he argues that “firing technologies may be characterized by a number of socially significant facets and cannot be reduced to ‘open’ and ‘kiln’ categories without a considerable loss of technical and cultural information” (2001, p. 999). Gosselain and Livingston Smith are undoubtedly correct to point out that estimating firing temperature cannot be considered an isolated core of a study of ancient firing technology and that instead it should form part of broader research into ancient technology, related to a specific archaeological question (cf. also Tite 1995). Indeed, archaeological practice has already moved beyond the pure estimation of firing temperature in ceramics studies. The specific questions considered include, for example, understanding the way in which temper can affect ceramic properties (Hein et al. 2008) or the manipulation of firing parameters according to the surface final effect to produced (Wilson and Day 1994). In this paper, firing technology is investigated to further an understanding of the presence or absence of technological patterns in the Neolithic–Bronze Age transition in Crete and to assess the hypothesis of radical change in ceramic technology.

Archaeological background

The Neolithic and Bronze Age in the Aegean have been often approached with contrasting ideas and assumptions of their economic and social structures, settlement patterns and technological advances. Neolithic communities, often thought of as self-sufficient and egalitarian, were thought to give way to more complex and specialised Bronze Age societies (for discussion cf. Tomkins 2004, 2014). While the radical changes between the Neolithic and the Early Bronze Age in Crete (=EBA, referred in the literature on the island as Early Minoan, EM, Table 1) to some were caused by the migration of people to Crete (cf. Weinberg 1965; Muhly 1973; Warren 1974; Treuil 1983; Hood 1990a, b), still others argued for autochthonous development of social and political structures (Renfrew 1972, pp. 474–475; Vagnetti 1972; Vagnetti and Belli 1978; Branigan 1988, p. 197). However, in both cases, the ideas were often based on evidence from poorly stratified sites, on confused chronologies and on differences in theoretical approaches (cf. Tomkins 2007, pp. 13–18; Schoep and Tomkins 2012; Nowicki 2014, pp. 5–9; Tomkins 2014).

Since the early excavations (Evans 1921), the materials found at Knossos deeply influenced discussion on the Neolithic–Early Bronze Age transition. The striking differences in shape, surface finish and decoration of the Neolithic ceramics from those of the EBA at Knossos were taken to indicate an equally radical social change (Evans 1921, pp. 35–62; Hood 1990a, pp. 372–373; Hood and Cadogan 2011, pp. 281–286). Burnished and incised vessels characteristic of the Neolithic phase were abruptly substituted in EBA by jugs with long spouted neck and rounded base with a characteristic dark pattern-painted decoration on a light background, lidded pyxides and bottles with incised decoration, large storage jars (pithoi) and chalices with pattern burnished decoration (Evans 1921, pp. 35–38 and 58–62). The later publication of the Neolithic assemblages from Phaistos (Vagnetti 1972) and Nerokourou (Vagnetti et al. 1989) made it clear for the first time that the latest part of the Neolithic could not be considered merely a transitional ceramic style that could be labelled in different ways according to the scholars’ preferences. Rather, it had to be considered a phase with its own characteristics distinguishing it from the previous and following phases in terms of material culture, settlement strategies, architectural features and engagement with other Aegean areas (cf. Vagnetti and Belli 1978, p. 161).

Since the 1970s, the latest phase of the Neolithic has been reconsidered, thanks to focused excavation campaigns, reviews of stratigraphy and detailed study of the pottery deposits. Systematic work has been carried out by other scholars at Knossos and Phaistos (for Phaistos cf. Di Tonto 2006; Todaro 2005, 2010, 2013; for Knossos cf. Wilson and Day 1994; Wilson and Day 2000; Tomkins 2007; Wilson 2007). Intensive survey and new excavations have extended our knowledge of the Neolithic in the rest of Crete (Haggis 2005; Hayden 2003; Papadatos 2008, 2012; Watrous et al. 2004). In recent years, this fieldwork has been supplemented by analysis of Final Neolithic (FN) and EM I pottery (Table 1; cf. Wilson and Day 1994; Day et al. 1998, 2005, 2012; Nodarou 2011, 2012; Papadatos et al., in press) and this has revealed a complex and multifaceted picture.

However, Betancourt (2008) has presented a review of pottery production in Crete at the beginning EBA, which advocates the idea of a ‘ceramic manufacture revolution’, linked to the arrival of people from outside Crete bringing new technologies. He has specified a number of changes: (1) the selection and manipulation of calcareous pastes, producing lighter coloured pottery; (2) the introduction of the up-draught kiln, which allowed better control of kiln atmosphere and the achievement of consistent, high temperatures of firing; and (3) the introduction of new painting technology, which allowed the creation of the dark-on-light style. According to Betancourt, while Neolithic ceramics were porous, coarse and low fired, those of the EBA were less porous and harder and thus more suitable to store and transport perishable goods, such as milk and cheese (2008, p. 99). He argued that the knowledge of the manipulation of such products was brought into Crete from the Near East, with the ‘secondary products revolution’ (Sherratt 1981,1983), with other advanced technologies, such as pyrotechnology and ceramic manufacturing techniques (Betancourt 2008, pp. 96–103). Betancourt’s technological reconstruction is supported by only limited evidence. Even if he acknowledges the presence of variability in Cretan ceramic fabrics, shape and surface treatment (2008, pp. 28–83), his pan-Cretan reconstruction regarding the Final Neolithic–Early Bronze Age (=FN-EBA) transition is based mainly on the analytical study of Aphrodite’s Kephali in East Crete (Betancourt et al. 2013).

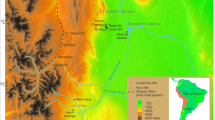

The recent project on pottery from Phaistos in south-central Crete (Fig. 1; Mentesana 2014, 2016; Mentesana et al. 2016) has focused on the technological reconstruction of ceramics from the latest phased of Neolithic to the earlier phases of Early Bronze Age (=FN-EBA), in order to assess this hypothetical change in ceramic technology. Compared to other sites in Crete, the FN III-EBA transition at Phaistos has a rather complete stratigraphic sequence and has benefited from a detailed consideration of phasing by Todaro (2010, 2013). The variety of wares available from these phases, from fine to coarse, allows us to discuss variation in technological choices used for ceramic manufacture both synchronically and diachronically. Taking its lead from Betancourt (2008) proposed technological revolution, this paper will investigate one aspect of the ceramic chaîne opératoire considered a key issue by the advocates of the technological revolution: firing.

Materials and methods

Materials

The ceramic material analysed belongs to the first four phases at Phaistos, as defined by Todaro (2010, 2013) and corresponds to FN III, IV, EM IA and EM IB of Tomkins’ chronological system for Crete (2007; Table 1). In calendar years, this time lapse includes the end of the fourth and the beginning of the third millennium (ca. 3600–2650 BC; cf. Tomkins 2007). Three hundred four ceramic samples were chosen from the most reliable stratigraphic contexts at the site (cf. Mentesana 2016). Samples were selected on the basis of previous typological work (cf. Vagnetti 1972; Di Tonto 2003, 2006; Todaro 2010, 2013) and they represent the ceramic variability encountered at the site during the four phases (Table 2 and Fig. 2). They are divided according to the ware system adopted for the ceramic studies in the island (cf. Wilson 1985; Wilson and Day 1994) which include shape and surface treatment as briefly described in Table 2. During FN III, ceramics were manufactured in a restricted number of main shapes (deep bowls, deep bowl on a cylindrical foot, V-shaped spouted jug and jug/jars, usually of globular body and long cylindrical neck) and most of these shapes have a black burnished surface (B or ScrB). In FN IV, the same shapes are present but with a varied surface treatment, such as black burnished (B or ScrB), red slipped and mottled (RS/M) or burnished and granulated (B/Gra). The shape repertoire of EM IA is difficult to define as the material is very fragmentary and it seems to be characterised by the mixing of new and old features in terms of both shape and surface treatment (Todaro 2013, 171): bowls with everted rims similar to those of FN IV are found beside typical feature of the following EM IB phase, such as pedestal bowls, globular jars/jugs, cooking pots and lidded pyxides. Few vessels show a red slipped and mottled surface as in FN IV, while dark-on-light painted (DOL) and dark burnished (DGPB) surfaces make their first appearance at the site. The brown slipped vessels (BrS/Po) are the most abundant ware in EM IA. The EM IB is instead defined by very distinctive shapes, such as chalices, ring-footed bowls, large jars, juglet, cooking pots and large storage jars (pithoi). The link between the surface treatment and the shape is marked in this phase, as observed in other EM I assemblages, such as at several sites from west Crete (Nodarou 2011), at Kephala Petras (Papadatos 2012) or at Knossos (Wilson and Day 1999): for example, chalices show a dark burnished surface, juglets and jars are always painted in dark-on-light background, and cooking pots have a typical scored surface. Therefore, while it can be acknowledged that changes occurred during these phases, it is crucial to understand whether it was a matter of a single ‘technological revolution’ as described by some literature based on firing procedures.

Example of wares sampled from phases I to IV at Phaistos. a Burnished (B) bowl. b Scribble burnished (ScrB) bowl. c Red slipped and mottled (RS/M) bowl. d Burnished and granulated (B/Gra) handle of a jar. e Orange Buff (O/Buff) bowl. f Brown slipped and polished (BrS/Po) handle. g Red burnished (RBW) chalice. h Dark grey pattern burnished (DGPB) chalice. i Coarse (Coarse) deep bowl. j Dark-on-Light (DOL) jar. k Wiped and washed (W&W) jar. l Light-on-dark (LOD) pyxis. m Pithos (PW). n Cooking pot (CPW). Bar = 5 cm. (Photos courtesy of the Italian School of Archaeology in Athens)

Methods

The integration of different analytical techniques and macroscopic observation is required for a better understanding of the firing process. All the 304 samples were prepared as thin sections with standard procedures and analysed under a polarised light microscope. Petrographic description was made according to the system developed by Whitbread (1989). Estimation of firing procedures was made by scanning electron microscopy coupled with energy dispersive spectroscopy (SEM-EDAX) and Fourier transform infrared spectroscopy (FT-IR), in addition to macroscopic observation of the colour developed by both body and surface during firing. This last feature was recorded for all the sampled ceramics from which 58 were selected for further analytical investigation (Table 3). Samples were chosen in order to represent the variability encountered in the main fabric and ware groups.

While acknowledging the limitation of such estimates, macroscopic examination of colour variation in the pot section and surface can be used to suggest the atmosphere developed during or in the last stage of the firing. Four definitions were chosen to define the materials from Phaistos based on macroscopic observations. Oxidising (O) and Reducing (R) atmosphere are used for those samples which show evidence of exposure to a constant atmosphere, respectively, abundant in oxygen or abundant in carbon monoxide. This usually results in a light colour in O atmosphere and dark colour in R atmosphere, evenly developed from core to margins. Ceramics, however, often show intermediate stages. Commonly, dark-coloured core and light-coloured margins are encountered or light-coloured core and dark-coloured margins. In the first case, it can be argued that the ceramics were exposed to an oxidising atmosphere in the last phase of the firing (defined as partly oxidised: Partly O) with the following concurring cases: (1) after a reducing phase or/and (2) the ceramic paste contains abundant organic material. In both cases, firing was not maintained for long enough to allow a complete oxidation of the paste. When accompanied by evidence of variably developed microstructure across the vessel section and of micro-bloating, it can be suggested that firing was of short duration, perhaps with a corresponding steep temperature gradient (Buxeda et al. 2003, p. 273; Tomkins 2001, p. 304). In the second case, samples are defined as fired in a partly reducing atmosphere (Partly R), in which reduction occurred at the end of the firing, but was not maintained for long enough to obtain a homogeneous colour across the section, as would be the case in a fully reducing atmosphere firing.

SEM examination was performed on 42 vessels, in fresh fracture (Tite et al. 1982) to observe microstructural changes and estimate firing temperature in terms of Teq (Tite and Maniatis 1975; Kilikoglou, in Wilson and Day 1994; Day and Kilikoglou 2001). EDAX analysis was used to obtain a semi-quantitative estimation of the chemical composition of different areas of the ceramic sample. The nomenclature used here for relative composition of the paste is low calcareous (< 6% CaO), calcareous (> 6% CaO) or high calcareous (> 10% CaO) paste, on the basis of CaO content. For FT-IR analyses, 30 samples were chosen, of which 14 were compared to the results obtained by SEM. FTIR samples were prepared using the potassium bromide pellet method (Berna et al. 2007) and FTIR spectra were collected in the range of 4000–400 cm−1. Van der Marel and Beutelspacher (1976) have been adopted as reference for band identification and the results interpreted following the literature on ceramics (Maniatis et al. 1982, 2002; Shoval 1988, 2003; Shoval and Beck 2005; Maritan et al. 2006; Berna et al. 2007; Papadopoulou and Maniatis 2013).

Results

Thin-section petrography

Petrographic results are presented briefly in order to note features that may have been influenced by firing (cf. Mentesana 2014; Mentesana 2016; Mentesana et al. 2016). The samples from Phaistos have been divided into 9 main fabrics and 26 loners on the basis of their petrographic features. Colour names are used to easily identify each fabric, and they are not related to the vessel colour. With the exception of the Green fabric, all the main fabrics are local, that means that the raw materials used for the vessels manufacture can be found in the vicinity of the site in a radius of 10 km. The production location of the pottery can be considered ‘broadly’ near Phaistos or at the site itself. Examination of pottery from Phaistos has suggested a possible shift in the location of ceramic production between the four phases (Mentesana et al. 2016; Mentesana 2016), but there is no clear evidence of ceramic production at the site or nearby prior to EM II (Todaro 2012). Petrographic groups are described as follow (Table 4):

-

Blue fabric (Fig. 3a) is a major fabric at the site, mainly used to manufacture pottery in FN III, but continued, in a few examples, up to EM IB. The paste is densely packed with quartz, feldspars and mica, plus a varied coarse fraction, mainly fragments of metaquartzite, silt/sandstones, bioclastic limestone and basalt; organics are occasionally present. The coarse vessels are manufactured by the addition of a coarser fraction of the same mineralogy. FN III samples present high internal variability in terms of mineralogy compared to samples from the subsequent phases. The possibility that this is due to raw material intra-source variability or/and to the exploitation of different sources cannot be excluded.

-

Yellowfabric (Fig. 3b) is a broad fabric used from FN III and its frequency increases throughout FN IV-EM IA to become one of the main fabrics in EM IB. It is composed of an orange/red-firing clay mixed with a wide range of rounded to well-rounded aplastic inclusions, mainly low-medium grade metamorphic, sedimentary and basic igneous rock fragments. The size distribution of the coarse fraction and the mineralogical differences between the coarse and the fine fraction (absence of fragments of basic igneous and low-medium grade metamorphic rocks in the fine fraction) suggest the use of temper. While the packing, sorting and size of the aplastic inclusions vary over time and within single phases, leading to the formation of several subgroups, this is a consistent recipe over time. This fabric offers a strong match with later material from Ayia Triadha (Belfiore et al. 2007) and Kommos (Day and Kilikoglou 2001; Day et al. 2011).

-

Violet fabric (Fig. 3c) is found in some samples from FN III and EM IA, mainly in EM IB. This fabric is composed of a densely packed fine fraction of mica, quartz, feldspar and more rarely amphibole and epidote with organics occasionally present. A coarse fraction occurs only rarely, as larger inclusions of mainly low-grade metamorphic rocks, chert, siltstones and quartzite as well as very rarely altered basalt. Some samples from Knossos for which a provenance from the Mesara was suggested match this fabric (Wilson and Day 1999, p. 39).

-

Green fabric (Fig. 3d) occurs in samples of FNIV and EM IA. Densely packed with well-sorted inclusions of limestone and sandstone, this fabric finds a broad comparison with the Early Neolithic fabrics identified at Knossos (Fabrics 1b and 2a, Tomkins 2001).

-

Orange fabric (Fig. 3e) includes samples belonging to EM IA but mainly to EM IB. The fabric comprises a very fine orange-firing clay with larger sub-angular inclusions of mixed mineralogy, ranging from phyllite/schist to siltstones and sandstones, to basalt degrading to serpentinite, as well as rare granodiorite. The coarse fraction appears to be added by the potter by the absence of the metamorphic, sedimentary and igneous rock fragments in the fine fraction. This fabric is characterised by fine red clay pellets and striations, which represent the best microscopic evidence of clay mixing.

-

Pink fabric (Fig. 3f) first appears in EM IA but seems to have been in use mainly in EM IB. It is characterised by a red/orange clay densely packed with quartz, feldspar, muscovite, biotite, epidote and amphibole, while the coarse fraction is composed of a wider range of metamorphic rocks (quartzite, metamorphosed limestone, amphibolite and gneiss, biotite schist, sillimanite-schist to chlorite phyllite), quartz sandstones/siltstones, calcite and plagioclase feldspars; rare altered basalt and shell fragment; and more frequent granodiorite and slate.

-

Purple fabric (Fig. 3g) is well attested in EM IA-B phases. The fabric is composed of a red-firing clay packed with a well-sorted fine fraction of mica, quartz and feldspar; larger inclusions of mixed mineralogy reflecting the mineralogy of the fine fraction occur rarely. The fabric presents some internal variability in terms of manipulation of the raw materials as some samples show signs of clay mixing. This fabric broadly matches with a group of LM IIIB short-necked amphorae from Kommos (Day et al. 2011).

-

Brown fabric (Fig. 3h) samples from this fabric belong exclusively to EM IB. Vessels are characterised by a yellow-firing, very fine clay containing some microfossils; a well-sorted and well-rounded coarse fraction of mixed nature (mainly quartz siltstones, lithic greywacke, metaquartzite, phyllite, biotite schist and gneiss) seems to have been added to the base clay. This fabric matches well some samples from the Kommos (Day and Kilikoglou 2001, Group 1, p. 116).

-

Red fabric (Fig. 3i) samples belong exclusively to EM IB and mainly to CPW. They are characterised by a coarse groundmass, densely packed with quartz, mica and amphibole and a coarse fraction of mainly medium-grade metamorphic rocks coupled with altered basic igneous rocks. The fabric has a close petrographic match to some of the wasters found in the Kommos kiln (Day and Kilikoglou 2001, Group 6, p. 117). This fabric includes also a DOL jar, which, however, shows evidence of possible clay mixing and it has been subgrouped for this reason.

Photomicrographs (XP) of the main fabrics from Phaistos. a Blue fabric (PHA 12/1). b Yellow fabric (PHA 12/241). c Violet fabric (PHA 12/91). d Green fabric (PHA 12/207). e Orange fabric (PHA 12/277). f Pink fabric (PHA 12/264). g Purple fabric (PHA 12/278). h Brown fabric (PHA 12/288). i Red fabric (PHA 12/267)

Macroscopic examination

FN III samples present two patterns in terms of colour variations (Table 5). Some show a uniform dark grey or brown section (Fig. 4a) and usually a brown surface which suggests exposure to a constant atmosphere, which is identified as O. Some other samples show a striking colour variation between core and surface, from dark grey core to sharp red margins (Fig. 4b). These features point to the presence of organic compounds in the paste and/or a drastic change of atmosphere during firing from reducing to oxidising. This is defined as Partly O, as it was not constantly maintained to allow full oxidation. In some cases, especially in vessels belonging to the B and ScrB, the surface is consistently black to dark brown, meaning that the atmosphere was reducing in the last stage of the firing and not maintained for long enough to allow a complete reduction of the vessel. In these cases, a Parly R label is added to identify the change in atmosphere at the final stage (Fig. 4a-b).

Fresh cut ceramic samples from Phaistos. a PHA 12/1 (B), Blue fabric. b PHA 12/42 (B), Violet fabric. c PHA 12/112 (ScrB), Blue fabric. d PHA 12/170 (B/Gra), Yellow fabric. e PHA 12/188 (BrS/Po), Blue fabric. f PHA 12/206 (BrS/Po), Yellow fabric. g PHA 12/267 (CPW), Red fabric. h PHA 12/277 (DOL), Orange fabric. i PHA 12/295 (DGPB), Violet fabric

Many of the samples from FN IV show the same variability (Table 5), but there is a higher proportion of samples showing striking variation in colour across the break (Fig. 4c). Those samples that have a black burnished surface (B and ScrB ware) can be considered, as in the previous phase, exposed to a Partly O-Partly R atmosphere. Those samples that show the same colour variations between core and margins but with a light-coloured surface (RS/M, B/Gra, Coarse and O/Buff ware) are considered exposed to a Partly O atmosphere. On the other hand, in the same phase, a few vessels belonging to the RS/M and B/Gra show a homogeneous orange colour in section and light-coloured surfaces and are identified as being fired in an O atmosphere (Fig. 4d). RS/M is also characterised by black mottled areas, which, however, would have required a specific procedure, not adopted here, to be investigated. The literature reports several methods to produce this effect, none of which can be excluded (Noble 1960; Farnsworth and Simmons 1963; Betancourt et al. 1979).

In EM IA and mainly in EM IB, the majority of vessels show a homogeneous light brown/orange colour through the section and on the surface (Table 5). Petrography suggests that organics are less frequent as in the previous phases and some fabrics seem to be more calcareous than others (such as the Yellow fabric, see Section 3.2), both factors which may promote a lighter body colour. However, most of the samples (Fig. 4e–h), regardless of fabric and ware, seem to be fired in a constantly maintained oxidising atmosphere, which allows the development of homogeneous colour through the section. Those vessels belonging to DGPB were fired in a R atmosphere, but they still show a homogeneously developed dark colour through section (Fig. 4i).

SEM-EDAX examination

Microstructures developed during firing, paste and surface composition are discussed here by phase and fabric, summarised in Table 6. Discussion of surface treatment is limited here to those carried out before firing and affected by temperature and atmosphere during firing (i.e. slipping, painting and burnishing), which can aid the reconstruction of firing practice.

Samples examined from FN III-IV belong to three different fabrics: Blue, Violet and Yellow. The samples of the Blue fabric show typical non-vitrified (NV) microstructure (Fig. 5a) in a low calcareous iron-rich paste. Samples from the Violet fabric were made also in a low calcareous paste, but microstructural differences between the core and the margins of the vessel, in the range of NV to initial vitrification/vitrification (IV/V) microstructure, can be observed (Fig. 5b, c). Yellow fabric samples were produced with a low calcareous paste which is higher in magnesium and develops a characteristic microporous microstructure probably due to its composition (Fig. 5d, e; cf. Maniatis et al. 1988, p. 270). Such samples also show micro-bloating in the core, which could suggest a fast-firing procedure (Fig. 5d, e; cf. Buxeda et al. 2003, p. 273; Tomkins 2001, p. 304). Sample 12/170 represents an exception amongst the Yellow fabric, being a high calcareous body, though the Yellow fabric does show high variability, either through source variability or inconsistent mixing.

Secondary electron micrographs of some ceramic samples examined from Phaistos. a PHA 12/1 (B), NV microstructure. b, c PHA 12/91 (B), IV microstructure at the section core (b), NV microstructure at the section margin visible under the layer of superficial decoration (c). d, e PHA 12/135 (O/Buff), V microstructure and micro-bloating at the section core (d), IV microstructure at the section margin (e). f PHA 12/295 (DGPB), IV microstructure. g PHA 12/206 (DGPB), NV microstructure. h PHA 12/282 (DOL), V microstructure. i PHA 12/267 (CPW), NV microstructure. j PHA 12/220 (Coarse), V microstructure. k PHA 12/278 (DOL), IV-V microstructure. l PHA 12/182 (W&W), NV microstructure

In terms of surface treatment, the examination of B and ScrB suggests that burnishing was performed directly on the body and did not involve the application of a slip: the surface raw material is the same as the body with higher concentrations of potassium and more rarely of aluminium, which is due to the alignment and compaction of fine clay particles by burnishing (cf. Kilikoglou and Maniatis 1993, p. 439; Kilikoglou, in Wilson and Day 1994, pp. 70–73). The microstructure of the vessel surface is flat and more compact compared to the body and it shows NV or IV stages (Fig. 6a). O/Buff vessels do not have such a flat, compact surface and the surface is of similar composition of the body. RS/M vessels have a thick layer on top of the body, which is higher in iron and lower in magnesium and calcium compared to the body (Fig. 6b). Amongst the RS/M vessels, only sample 12/132 shows no chemical and microstructural difference between the body and the surface. The surface layer looks to be a well-flattened portion of the body, which being high in iron and low in calcium paste, suggesting the vessel was slipped (Fig. 6c). This vessel seems to be an exception amongst the others. B/Gra vessels are produced by applying a surface material different to that of the body: EDAX analysis shows a layer with raised iron and potassium and lower in calcium and magnesium compared. The roughness of the surface may be due to tempering with sand-size aplastic inclusions, resulting in the characteristic granulated appearance. The microstructure developed by the surface layer is typical of low calcareous clay (Fig. 6d).

Secondary electron micrographs of the surface of some ceramic samples examined from Phaistos. a PHA 12/1 (B). b PHA 12/119 (RS/M). c PHA 12/132 (RS/M). d PHA 12/170 (B/Gra). e PHA 12/295 (DGPB). f PHA 12/188 (BrS/Po). g PHA 12/225 (BrS/Po). h PHA 12/242 (DOL). i PHA 12/207 (BrS/Po). j PHA 12/289 (DOL). k PHA 12/288 (DOL). l PHA 12/284 (W&W)

The examination of EM IA-B samples reveals a picture of continuity and change. In addition, new fabric groups (Brown, Green, Orange, Pink, Purple and Red) appear and in the EM IB are linked with the production of specific wares (e.g. the Red and Pink fabric were used mainly for cooking pots; the Purple, Brown and Orange fabric for DOL and W&W; cf. Mentesana et al. 2016).

Samples belonging to the Blue and Violet fabric (CPW, DGPB, RBW, BrS/Po) show NV to IV microstructure (Fig. 4f), manufactured in a low calcareous paste and burnished directly on the body, without application of a slip, as was the case in previous phases (Fig. 6e). This is particularly significant in the case of samples 12/188 which as BrS/Po might have been expected to be slipped. However, the surface is a continuum with the body from the microstructural and chemical examination (Fig. 6f).

Samples from the Yellow fabric indicate a change in firing temperatures and the use of a more calcareous paste compared to the previous phases. Specifically, EM IA samples show NV to IV microstructure (Fig. 5g) as did the samples from the Blue and Violet fabric. In contrast, in EM IB, microstructures range from IV to total vitrification (TV) (Fig. 5h). In terms of surface treatment, the Yellow fabric was still used to manufacture mainly slipped and slipped and painted ware. The slip of BrS/Po is highly varied in our samples, but, compared to the body, all the slips are lower in calcium and higher in iron. The slips are thinly applied compared to the RS/M and subsequently burnished, producing a well-flattened layer (Fig. 6g). Despite the fact that macroscopically most of the samples seemed slipped with a creamy white substance and painted with a red substance afterwards, the samples analysed of DOL and W&W do not show any slip layer distinguishable from the body: the paint layer seems to have been applied directly on the body. Figure 6g shows the surface of sample 12/242: the top layer is composed of a material lower in calcium and magnesium and higher in iron and potassium, which has a dense V microstructure; this layer is applied directly on the body. LOD presents the opposite colour contrast on the surface: cream-white pattern on a red background. Sample 13/5 is examined from the surface down in order to better identify the different layers: the red slip is composed of a material high in iron and low in calcium, while the creamy white paint is similar in composition to the body, but contains higher calcium compared to the slip. No information on microstructure could be retrieved.

Greater variability is observed in other fabrics. The Green fabric sample, 12/207 (BrS/Po), has a high-calcareous paste and shows NV microstructure. The surface is slipped with an iron-rich, low calcium material, as are other samples from the same ware (Fig. 6h). The Red fabric includes sample 12/214 (CPW), which has a low calcareous paste, with NV microstructure (Fig. 5i), and 12/289 (DOL) which is made in a high-calcareous paste and higher fired. Petrography already suggested differences between these samples (see Section 3.1). In contrast to the other DOL samples, 12/289 shows two distinct layers on top of the body: the first composed of a material similar to the body but higher in calcium and potassium and lower in silica, which can be identified as the cream-white slip; the second layer, a red paint, is lower in calcium and magnesium and higher in iron. The two layers differ also in microstructure, the slip has a typical microsctructure of calcareous materials, while the paint shows a dense microstructure (Fig. 6j). Similarly, the DOL sample from the Brown fabric shows two thin layers of different composition (an iron-rich paint on a calcium-rich slip) but has a high calcareous paste with V microstructure (Fig. 6k). The two samples of the Orange fabric display IV to V microstructure, but, while similar in thin section, they show the use of low calcareous and calcareous paste, respectively (Fig. 5j). Samples from the Purple fabric are relatively high fired, all showing V microstructure, in a low calcareous paste, high in iron and magnesium, which shows a microstructure with clay filaments leaving mainly elongated pores (Fig. 5k). Sample 12/284, on the other hand, has higher calcium and magnesium, and a not dissimilar microstructure, but with larger spherical pores. The sample from Pink fabric, 12/182 (W&W), is made with a calcareous paste and shows NV microstructure (Fig. 5l). The surface treatment of DOL and W&W in the Orange, Purple and Pink fabrics seems to have been produced by applying an iron-rich paint directly to the body, as in the Yellow fabric samples. For example, in samples 12/182 and 12/284 (Fig. 6l), a thin layer was identified, with lower calcium and magnesium compared to the body. This layer seems applied directly on the vessel body, without the application of a light-coloured slip as background.

FT-IR examination

The shift in the main bands of FT-IR spectra is caused by a change in the crystalline and amorphous phases in the sample due to temperature increase (cf. Weiner 2010, pp. 300–306). The bands considered related to firing temperature increase are the main SiO stretching band shifting between 1029 and 1086 cm−1; the SiO and AlO deformation bands shifting between 472 and 460 cm−1 and between 527 and 554 cm−1; the presence of the OH stretching band (around 3620 cm−1) which disappears around 600 °C; and the presence of the CO3 band (1430/876 cm−1) which, depending on amount and size of calcitic inclusions (Shoval et al. 1993), disappears around 700–750 °C. Figure 7 shows some of the FT-IR spectra according to fabric, while Table 7 presents the results for each sample.

Blue fabric

Most samples from FN III show a narrow shift of the SiO stretching band from 1030 to a maximum of 1035 cm−1, a SiO, AlO deformation band around 520–527 cm−1 and an OH stretching band around 3620 cm−1 (Fig. 7:a). Amongst these samples, 12/35, 12/51 and 12/90 show lower wavenumbers for the SiO, AlO deformation bands, while all the others show wavenumber around 474–471 cm−1. Few other samples from FN III and all those from FN IV show higher wavenumbers for the SiO stretching band with two major peaks at around 1030/1080 cm−1 and the SiO, AlO bands around 460 cm−1 (Fig. 7b). Those might have a peak around 554 cm−1. In contrast, samples from EM IA show the same band shifts of FN III samples. The presence of a CO3 band at 1427/876 cm−1 in some samples is due to the presence of calcitic inclusions in the paste, which occasionally occurs in this fabric, and to a firing temperature below the calcite decomposition.

Violet fabric

The FN III samples and sample 12/295 from EM IB show a rather broad SiO stretching band and mainly with two peaks around the 1030/1080 cm−1 wavenumber, low wavenumber of the SiO, AlO deformation bands around 460 cm−1 and some a shoulder around 554 cm−1 (Fig. 7c). In contrast, 12/187 (EM IA) and 12/293 (EM IB) show lower wavenumber for the SiO stretching band, higher for the SiO, AlO deformation bands a band around 527 cm−1 and the characteristic OH band (Fig. 7d). Only 12/57 show the presence of a CO3 band.

Yellow fabric

The FT-IR spectra of these samples show a SiO stretching band splitting into two main peaks around 1040 and 1080 cm−1 (Fig. 7e). Amongst the other samples, 12/87 show the highest wavenumber at 1088 cm−1 (Fig. 7f). The SiO, AlO def. band is shown at around 460 cm−1 and sometime as a doublet and most of the samples show a peak at 554 cm−1. None of the samples show an OH stretching band. All the samples show the CO3 band1, less defined in samples 12/87 and 138. SEM-EDAX and petrographic examination have shown that this fabric has a higher calcium content in the micromass and more calcitic inclusions when compared to the previous fabrics.

Pink fabric

The two samples from the Pink fabric show the SiO band at around 1033 cm−1. Sample 12/264 shows also an OH stretching band shoulder at 3620 cm−1 and a SiO, AlO def. band at 470 and 527 cm−1 (Fig. 7g). Sample 12/182 shows a shift for the same bands that can allow a distinction between the two samples (Fig. 7h). Both have a large CO3 peak at 1427/876 cm−1 and a small at 712 cm−1 as the previous fabric group. At least for 12/182, SEM-EDAX analysis confirmed that the paste is calcareous.

Other characteristic bands observed in all the samples are those in the wavenumber range of 797–778 and 694 cm−1 which are due to the quartz contents; an OH deformation band at 1630 cm−1 which comes from the absorbed atmospheric water; the doublet at 2921 and 2853 cm−1 which is due to the presence of organic matter. The major part of the samples shows a peak around 648 cm−1 probably related to the chlorite minerals group or to post-depositional contamination and few other (12/128, 138, 187) peaks linked with the feldspars group around 722–727 cm−1.

Discussion

The combination of analytical techniques and macroscopic examination is often used to assess firing in terms of firing temperature ranges and atmosphere. However, the works of Gosselain (1992) and Livingstone Smith (2001) suggest that the heating rate (i.e. the rate of temperature development up to the maximum temperature) and the soaking time (i.e. time of exposure to the maximum temperature) are the only variables that allow a distinction between different firing structures The recent experimental work by Thér (2014) supports this view: one-space firing (vessel in contact with the fuel, such as in pit fire or bonfire) develops fast heating rates and short soaking times, which can result in significant difference in temperature of core and margins of the vessel. On the contrary, two-space firing (vessels and fuel are separated, such as in two-chamber kiln) has a slow heating gradient and longer soaking times, allowing the development of microstructural and mineralogical changes along the vessel walls. Leaving aside for now the distinction between different structures, some of these features were observed during the examination of the material from Phaistos and allow us to discuss firing procedures beyond the definition of equivalent firing temperature, considering as much as we can also the atmosphere, heating rate and soaking time developed during firing (cf. Table 8). In terms of the temperature range, the microstructural, chemical and mineralogical changes observed allow us to group samples into:

-

Very low fired: Vessels in this range show a nNV microstructure, the presence of molecular vibrations for crystalline water and specific amorphous phases. In specific, the samples show the SiO str. band below or around 1035 cm−1 and the OH stretching band at around 3620 cm−1; the SiO, AlO def. band can be around 470 and at 527 cm−1, but some samples do show other wavenumbers (cf. 12/90).

-

Low fired: Compared to the previous range, vessels show the same NV microstructure but a change in the molecular vibrations of the amorphous phases: they lose the OH stretching band and the SiO, AlO deformation band shifts at 554 cm−1.

-

Medium fired: Vessels in this range show a change of the microstructure to IV and a change of the amorphous and crystalline phases, which suggests they were fired at a higher temperature than the low fired range vessels. The samples show the SiO str. band splits into two peaks, in the range of 1045 and 1078 cm−1 as result of changes in the clay crystalline structure upon heating (cf. Berna et al. 2007; Shoval and Becks 2005). The SiO, AlO def. band shifts at wavenumbers around 460 and at 554 cm−1, but the samples show marked variation. The CO3 band may be still present depending on the size and distribution of calcitic inclusions.

-

High fired: vessels in this range show a V to TV microstructure and a further change in the molecular vibrations of the crystalline phases by showing the SiO str. narrowing around 1080 cm−1 and SiO, AlO def. band at 554 cm−1 disappears and in those samples characterised by calcitic inclusions the CO3 band is reduced or disappears.

These changes may be correlated to ranges of temperature by comparing them with the published comparative material (cf. Section 2.2): a temperature of maximum 600 °C, 700 °C, 800 °C and between 800 and 1150 °C can be estimated respectively for the very low fired, low fired, medium fired and high fired group. However, the temperature range has to be considered as a broad estimate, as the comparative data are very different from those used for the pottery from Phaistos.

More importantly, microstructural variation when coupled with the examination of colour across the vessel section is helpful in estimating firing heating rates and soaking times. Those vessels which show consistently developed microstructure and colour from the core to the margins suggest they were exposed to slow heating gradient and longer soaking times. When these conditions occur, the vessel is discussed in terms of slow firing. In contrast, some vessels show variability in the microstructure, often with micro-bloating, and variation in the colour developed from the core to the margins, suggesting they were exposed to variable firing conditions in a short amount of time, which can be the result of fast heating rates and short soaking times. Fast firing procedures are considered responsible for such results. Only vessels analysed with SEM can be included in these two groups, as they rely on observation of micro-bloating and microstructure. However, some comments can be made regarding other samples as colour variation can be an indication of fast or slow firing. For example, the B ware of FN III shows sharp colour changes through the section from black core to red margins to a black surface. In this case, it can be argued that the vessel was exposed to a Partly O-Partly R atmosphere but with short soaking time which did not allow the full reduction of the vessel along the section. The carbon deposition technique or smudging is known in the literature to produce similar results (Rice 1987, p. 335). The macroscopic examination of colour differences on vessel body and surface, coupled with their examination with SEM-EDAX, shows potters’ choices in firing procedure towards the achievement of desired vessels appearance by manipulating surface treatment and firing atmosphere accordingly.

The definition of these interpretative parameters is crucial in the interpretation of changes in firing procedure over the FN III-EM IB at Phaistos (Table 8 and Fig. 8). In terms of firing temperature range, this study shows that in FN III the majority of the vessels belong to the very low to low fired range and only a few samples to the medium to high fired range. In FN IV, the vessels belong to the medium fired range increases compared to the previous phase, but vessels still share the characteristics of the low fired range. In EM IA, most of the samples analysed belong to the low fired range, as in FN III. All the ranges, from very low to high fired, are represented in EM IB but, in contrast to the previous phases, this is clearly linked with fabric and ware. CPW, DGPB and RBW belong to the low fired range, which occurs in the Blue, Violet, Red and Pink fabrics. DOL, LOD, W&W and PW are fired in the medium/high fired range and those belong to the Yellow, Purple, Brown and Orange fabrics.

In terms of the firing rate, in FN III-IV, the majority of the vessels analysed show evidence of being subjected to firing in variable conditions, indicated as fast firing. In sharp contrast, samples from EM IA-B show features suggesting that vessels were exposed to a rather constant firing atmosphere, long enough to allow the development of homogeneous colour and microstructural characteristics through the vessel’s cross-section, interpreted as slow firing. This change from fast to slow firing procedures over the phases considered was observed in all the sampled materials.

The examination of the material from Phaistos shows that potters manipulated the firing atmosphere (reducing or oxidising) on the basis of the desired final effect. The black/brown surfaces of B, ScrB and DGPB are obtained by simply burnishing the vessel and changing the atmosphere to reducing at the end of the firing. The light brown surface of O/Buff is obtained by smoothing the surface and by firing in an oxidising atmosphere. In contrast, the similarly light brown BrS/Po were slipped with an iron rich material, burnished and then fired in an oxidising atmosphere. For the slipped or painted wares, such as the RS/M, B/Gra, DOL and LOD, an iron-rich or calcium-rich material was applied pre-firing, according to the desired effect and then vessels fired in an oxidising atmosphere (Mentesana et al. 2016).

In conclusion, do these results confirm or refute the adoption of different firing structures over time, i.e. switching between an open firing and a kiln firing, as suggested by Betancourt (2008)? With regard to the material from Phaistos, the pattern observed between phases indicates that firing procedures did change in terms of potters’ control over the firing conditions towards the beginning of the EM IA in terms of temperature rate. It can be argued that this corresponds to a technical change and to the introduction of an equipment which allowed better control of the firing, such as a ‘kiln’ or a form of double-space firing (Thér 2014).

However, the study of the material from Phaistos has a more meaningful outcome than solely considering ‘open’ or ‘kiln’ firing: by EM IA, potters working at or near Phaistos had acquired and transmitted the different skills needed to perform a controlled firing. The use of any equipment or tools requires knowledge and skills which come with transmission and practice (Bourdieu 1977, 1984; van der Leeuw 1984). The equipment to perform a controlled firing might have been present and used in Crete before the EBA, but it is at that point in time that potters managed to use it in a different way. As this change involved the entire assemblage found at Phaistos, rather than one set of vessels, it can be argued that the transmission of knowledge and its practice involved the entire potters’ community. Adopting the concept developed by Lave and Wenger (1991) and Wenger (1998), the potters can be seen as a community of practice where individuals engage in social learning and produce materials that reflect this shared activity and experience. Novelties, like the use of a new equipment, can be rejected or integrated into the set of shared knowledge and became a common practice for the entire community. A similar process might have taken place in the case of firing procedures at Phaistos during the FN-EBA transition.

Conclusion

The detailed study of firing technology on FN-EM I ceramic material from Phaistos provides more material for discussion of a supposed change in ceramic technology in this period. Our results support the idea of a change in firing at the beginning of the EBA, consisting of improved control of firing in terms of duration, temperature and atmosphere. This produces vessels with homogeneously microstructure and colour through the vessel section. This change seems not to be linked with the achievement of high temperature firing nor to any specific ware produced. It rather includes all the wares found at the site, which seem initially to be preferably fired at low temperature ranges. Potters were aware since the Final Neolithic of the ways in which to obtain dark or light-coloured surfaces by manipulating the amount of oxygen present during firing and therefore this is not a feature that can be considered typical of EM phases. Reducing and oxidising firing, while present since the earlier phases, stand visibly in great contrast by the end of EM I, when painted jugs-jar, painted pyxid and pithoi (DOL, W&W, LOD, PW) are constantly fired at high temperature and in oxidised atmosphere compared to the low and reduced firing used for dark burnished chalices (DGPB) and cooking pots (CPW).

The picture emerging from other studies in Crete for the same phases seems similar. Wilson and Day (1994) observed that potters in EM I Crete adopted different firing procedures in terms of atmosphere and temperature according to the ceramic ware being manufactured. A similar picture was suggested for EM I ceramics in west Crete (Nodarou 2011). The study of FN IV-EM I material from Kephala Petras revealed that firing procedures in EM I changed slightly compared to those of the FN, entailing a better control of atmosphere (Papadatos et al., in press). Do these data allow us to suppose the introduction of new firing structure in the procedures used by potters at Phaistos and more widely in Crete? It is difficult to give a confident answer to this, as there is currently no primary evidence on the island for structures of this kind. More importantly, this can be considered only one aspect of research into firing technologies and in the reconstruction of technological change in ceramics from Phaistos.

Of course, the reconstruction of firing technologies is of uncertain value if not embedded in an understanding of all the other steps of the vessel production sequence and of its context of consumption. In a recent paper (Mentesana et al. 2016), it has been argued that by the end of the EM I a novel consumption etiquette (cf. also Hood and Cadogan 2011), which involved the entire island, channelled ceramic manufacture to the production of specific ware according to specific technological choices. Those are not totally novel in the local manufacture at Phaistos, but they comprise a re-elaboration, creating distinct wares from both visual and technological point of view. In a few words, the change in firing technology, whatever it implies in terms of change of equipment used, is just the tip of the iceberg of much wider technical and cultural transformations happening at the site in the FN-EM transition.

References

Belfiore CM, Day PM, Hein A, Kilikoglou V, La Rosa V, Mazzoleni P, Pezzino A (2007) Petrographic and chemical characterization of pottery production of the Late Minoan I Kiln at Haghia Triada, Crete. Archaeometry 49(4):621–653. https://doi.org/10.1111/j.1475-4754.2007.00324.x

Berna F, Behar A, Shahack-Gross R, Berg J, Boaretto E, Gilboa A, Weiner S (2007) Sediments exposed to high temperatures: reconstructing pyrotechnological processes in Late Bronze and Iron Age Strata at Tel Dor (Israel). J Archaeol Sci 34(3):358–373. https://doi.org/10.1016/j.jas.2006.05.011

Betancourt PP, Gaisser TK, Koss E, Lyon R, Matson FR, Montgomery S, Myer GH, Swann CP (1979) Vasilike ware: an Early Bronze Age pottery style in Crete. In: SIMA 56. Paul Astrom, Goteborg

Betancourt PP (2008) The Bronze Age begins: the ceramics revolution of Early Minoan I and the new forms of wealth that transformed prehistoric society. INSTAP Academic Press, Philadelphia

Betancourt PP, Chalikias K, Dierckx HMC, Koh AJ, Margaritis E, McCoy FW, Nodarou E, Reese DS (2013) Aphrodite’s Kephali: an Early Minoan I defensive site in eastern Crete. INSTAP Academic Press, Philadelphia

Bourdieu P (1977) Outline of a theory of practice. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511812507

Bourdieu P (1984) Distinction: a social critique of the judgment of taste. Harvard University Press, Harvard

Branigan K (1988) The foundations of palatial Crete: a survey of Crete in the Early Bronze Age, 2nd edn. Routledge, London

Buxeda i, Garrigós J, Jones RE, Kilikoglou V, Levi ST, Maniatis Y, Mitchell J, Vagnetti L, Wardle K, Andreou S (2003) Technology transfer at the periphery of the Mycenaean world: the cases of Mycenaean pottery found in Central Macedonia (Greece) and the plain of Sybaris (Italy). Archaeometry 45(2):263–284. https://doi.org/10.1111/1475-4754.00108

Day P M, and Kilikoglou V (2001) Analysis of ceramics from the kiln. In: Shaw J W, van de Moortel A, Day P M and Kilikoglou V, A LMIA ceramic kiln in south-Central Crete. Function and pottery production. Hesperia supplement 30, pp 111–133

Day PM, Joyner L, Kiriatzi E, Relaki M (2005) Petrographic analysis of some final Neolithic–Early Minoan II pottery from the Kavousi area. In: Haggis DC (ed) Kavousi I: the archaeological survey of the Kavousi Region. INSTAP Academic Press, Philadelphia, pp 177–195

Day PM, Hein A, Joyner L, Kilikoglou V, Kiriatzi E, Tsolakidou A, Wilson DE (2012) Petrographic and chemical analysis of pottery from the cemetery of Hagia Photia, Siteia. In: Betancourt PP, Davaras C (eds) Hagia Photia II. The pottery. INSTAP Academic Press, Philadelphia, pp 115–146

Day PM, Rutter JB, Quinn PS, Kilikoglou V (2011) A world of goods: transport jars and commodity exchange at the late Bronze Age harbor of Kommos, Crete. Hesperia 80:511–558

Day PM, Wilson DE, Kiriatzi E (1998) Pots, labels and people: burying ethnicity in the cemetery of Aghia Photia, Siteias. In: Branigan K (ed) Cemetery and society in the Bronze Age, Sheffield studies in Aegean archaeology, vol 1. Sheffield Academic Press, Sheffield, pp 133–149

Di Tonto S (2003) La ceramica neolitica dei nuovi scavi di Festòs, Specialization Dissertation. Scuola Archeologica Italiana di Atene

Di Tonto S (2006) Considerazioni preliminari sulla ceramica neolitica dei recenti scavi di Festòs. Annuario della Scuola Archeologica Italiana ad Atene LXXXII 4 (II): 413–428

Edwards WI, Segnit ER (1984) Pottery technology at the chalcolithic site of Teleicat Ghassul (Jordan). Archaeometry 26(l):69–77. https://doi.org/10.1111/j.1475-4754.1984.tb00319.x

Evans AJ (1921) The palace of Minos at Knossos, vol 1, London

Farnsworth M, Simmons I (1963) Colouring agents for Greek glazes. Am J Archaeol 67(4):389–396. https://doi.org/10.2307/501622

Gosselain OP (1992) Bonfire of the enquiries. Pottery firing temperatures in archaeology: what for? J Archaeol Sci 19(3):243–259. https://doi.org/10.1016/0305-4403(92)90014-T

Haggis DC (2005) Kavousi I: the archaeological survey of the Kavousi Region. Prehistory monographs 16. INSTAP Academic Press, Philadelphia

Hayden B (2003) Final Neolithic-Early Minoan I-IIA settlement in the Vrokastro Area, Eastern Crete. Am J Archaeol 107(3):363–412. https://doi.org/10.3764/aja.107.3.363

Hein A, Müller N, Day PM, Kilikoglou V (2008) Thermal conductivity of archaeological ceramics: the effect of inclusions, porosity and firing temperature. Thermochim Acta 480(1–2):35–42. https://doi.org/10.1016/j.tca.2008.09.012

Hood S (1990a) Settlers in Crete c. 3000 B. C. Cretan. Studies 2:150–158

Hood S (1990b) Autochthons or settlers? Evidence for immigration at the beginning of the Early Bronze Age in Crete. Πεπραγμένα του ΣΤ΄ Διεθνούς Κρητολογικού Συνεδρίου: 367–375

Hood S and Cadogan G (2011) Knossos excavations, 1957-1961: Early Minoan. British School at Athens Supplementary volume 46. London

Kaiser T, Lucius W (1989) Thermal expansion measurement and the estimation of prehistoric pottery firing temperatures. In: Bronitsky G (ed) Pottery technology. Ideas and approaches. Westview Press, Boulder, pp 83–100

Kilikoglou V, Maniatis Y (1993) Technological study of Neolithic ceramics from Tharounia and Psachna, Euboea. In: Sampson A (ed) Skoteini, Tharrounia: the cave, the settlement and cemetery. Dept. of Paleoanthology-Speology, Athens, pp 438–441

Lave J, Wenger E (1991) Situated learning: legitimate peripheral participation. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511815355

Livingstone Smith A (2001) Bonfire II: the return of pottery firing temperatures. J Archaeol Sci 28(9):991–1003. https://doi.org/10.1006/jasc.2001.0713

Maniatis Y, Katsanos A, Caskey ME (1982) Technological examination of low-fired Terra cotta statues from Ayia Irene Keos. Archaeometry 24(2):191–198. https://doi.org/10.1111/j.1475-4754.1982.tb01001.x

Maniatis Y, Perdikatsis V, Kotsakis K (1988) Assessment of in-site variability of pottery from Sesklo, Thessaly. Archaeometry 2(30):264–274

Maniatis Y, Facorellis Y, Pillali A and Papanthimou-Papaefthimiou A (2002) Firing temperature determinations of low fired clay structures. In: Kilikoglou V, Hein A and Maniatis Y (eds) Modern trends in scientific studies on ancient ceramics. BAR International Series, 1011: 59–68

Maritan L, Nodari L, Mazzoli C, Milano A, Russo U (2006) Influence of firing conditions on ceramic products: experimental study on clay rich in organic matter. Appl Clay Sci 31(1-2):1–15. https://doi.org/10.1016/j.clay.2005.08.007

Mentesana R (2014) The Final Neolithic-Early Minoan transition in Phaistos, Crete: continuity and change in pottery manufacture. In Kassianidou V and Dikomitou-Eliadou, M (eds) The NARNIA project: integrating approaches to ancient material studies. Nicosia, the NARNIA project, pp 20–31

Mentesana R (2016) The Final Neolithic-Early Bronze Age transition in Phaistos, Crete: an investigation of continuity and change in ceramic manufacture. PhD Dissertation, University of Sheffield

Mentesana R, Day PM, Kilikoglou V, Todaro S (2016) United in our differences: the production and consumption of pottery at EMIB Phaistos, Crete. J Archaeol Sci Rep 7:489–498

Muhly JD (1973) Copper and tin: the distribution of mineral resources and the nature of the metals trade in the Bronze Age. Archon Books, Hamden

Noble JV (1960) The technique of attic vase-painting. Am J Archaeol 64(4):307–313. https://doi.org/10.2307/501329

Nodarou E (2011) Pottery production distribution and consumption in Early Minoan West Crete: an analytical perspective. British Archeological Report 2210

Nodarou E (2012) Pottery fabrics and recipes in the Final Neolithic and Early Minoan I period: the analytical evidence from the settlement and the rock shelter of Kephala Petras. In: Tsipopoulou M (ed) Petras, Siteia—25 years of excavations and studies. Monographs of the Danish Institute at Athens 16. The Danish Institute at Athens, Athens, pp 81–88

Nowicki K (2014) Final Neolithic Crete and the Southeast Aegean. Boston-Berlin, DeGruyter. https://doi.org/10.1515/9781614510376

Papadatos Y (2008) The Neolithic Early Bronze Age transition in Crete: new evidence from the settlement at Kephala Petras, Siteia. In: Isaakidou V, Tomkins P (eds) Escaping the labyrinth: the Cretan Neolithic in context, Sheffield studies in Aegean archaeology, vol 8. Oxbow Books, Oxford, pp 261–275

Papadatos Y (2012) Back to the beginnings: the earliest habitation at Petras on the basis of the evidence from the FN-EM I settlement on Kephala. In: Tsipopoulou M (ed) Petras, Siteia—25 years of excavations and studies, Monographs of the Danish Institute at Athens Volume 16. The Danish Institute at Athens, Athens, pp 69–80

Papadatos Y, Tomkins P, Nodarou E, Iliopolous Y (in press) The beginning of the Early Bronze Age in Crete: continuities and discontinuities in the ceramic assemblage at Kephala Petras, Siteia. In: Doumas C, Giannikouri A, Kouka O (eds) The Aegean Early Bronze Age: new evidence. International conference, Athens April 11th-14th

Papadopoulou E, Maniatis Y (2013) Reconstructing thermal food processing techniques: the application of FTIR spectroscopy in the analysis of clay thermal structures from Early Bronze Age Archontiko. In: Voutsaki S, Valamoti SM (eds) Diet, economy and society in the ancient Greek world. Towards a Better Integration of Archaeology and Science. Proceedings of the International Conference held at the Netherlands Institute at Athens on 22–24 March 2010. Pharos Supplement 1. Peeters, Leuven-Paris-Walpole, pp 113–122

Perinet G, Courtois L (1983) Evaluation des temperatures de cuisson de céramiques et de vaisselles blanches néolithiques de Syrie. Bulletin de la Sociét é Préhistorique Française 80(5):157–160. https://doi.org/10.3406/bspf.1983.5436

Renfrew C (1972.) The emergence of civilisation: the Cyclades and the Aegean in the third millennium B.C. London, Methuen

Rice PM (1987) Pottery analysis: a sourcebook. University of Chicago Press, Chicago

Roberts JP (1963) Determination of the firing temperature of ancient ceramics by measurement of thermal expansion. Archaeometry 6(1):21–25. https://doi.org/10.1111/j.1475-4754.1963.tb00574.x

Schoep I, Tomkins P (2012) Back to the beginning for the Early and Middle Bronze Age in Crete. In: Schoep I, Tomkins P, Driessen JM (eds) Back to the beginning: reassessing social and political complexity on Crete during the Early and Middle Bronze Age. Oxbow Book, Oxford, pp 1–31

Schoep I, Tomkins P, Driessen JM (2012) Back to the beginning: reassessing social and political complexity on Crete during the Early And Middle Bronze Age. Oxbow Book, Oxford

Sherratt AG (1981) Plough and pastoralism: aspects of the secondary products revolution. In: Hodder I, Isaac G, Hammond N (eds) Pattern of the past. Cambridge University Press, Cambridge, pp 261–306

Sherratt AG (1983) The secondary products revolution of animals in the Old World. World Archaeol 15(1):90–104. https://doi.org/10.1080/00438243.1983.9979887

Shoval S (1988) Mineralogical changes upon heating calcitic and dolomitic marl rocks. Thermochim Acta 135:243–252. https://doi.org/10.1016/0040-6031(88)87393-3

Shoval S (2003) Using FT-IR spectroscopy for study of calcareous ancient ceramics. Opt Mater 24(1-2):117–122. https://doi.org/10.1016/S0925-3467(03)00114-9

Shoval S, Beck P (2005) Thermo-FTIR spectroscopy analysis as a method of characterizing ancient ceramic technology. J Therm Anal Calorim 82(3):609–616. https://doi.org/10.1007/s10973-005-0941-x

Shoval S, Gaft M, Beck P, Kirsh Y (1993) Thermal behaviour of limestone and monocrystalline calcite tempers during firing and their use in ancient vessels. J Therm Anal 40(1):263–273

Thér R (2014) Identification of pottery firing structures using the thermal characteristics of firing. Archaeometry 56:78–99. https://doi.org/10.1111/arcm.12052

Tite MS (1995) Firing temperature determination: how and why? In: Lindhal A, Stilborg O (eds) The aim of laboratory analysis in archaeology, vol 34. KVHAA Konferenser, Stockholm, pp 37–42

Tite MS, Maniatis Y (1975) Examination of ancient pottery using the scanning electron microscope. Nature 257(5522):122–123. https://doi.org/10.1038/257122a0

Tite MS, Freestone IC, Meeks ND, Bimson M (1982) The use of scanning electron microscopy in the technological examination of ancient ceramics. In: Olin JS, Franklin AD (eds) Archaeological ceramics. Smithsonian Institution Press, Washington, pp 109–120

Todaro S (2005) EMI–MMIA ceramic groups at Phaistos: towards the definition of a Prepalatial ceramic sequence in South Central Crete. Creta Antica 6:11–54

Todaro S (2010) The Phaistos hills before the palace: a chronological and functional re-assessment. PhD Dissertation. University of Sheffield

Todaro S (2012) Craft production and social practices at prepalatial Phaistos: the background to the first 'Palace'. In: Schoep I, Tomkins P, Driessen JM (eds) Back to the beginning for the Early and Middle Bronze Age on Crete. Oxbow Books, Oxford, pp 195–235

Todaro S (2013) The Phaistos hills before the palace: a contextual reappraisal. Praehistorica Mediterranea 5. Monza, Polimetrica

Tomkins P (2001) The production, circulation and consumption of ceramic vessels at Early Neolithic Knossos, Crete. Unpublished PhD Thesis, University of Sheffield

Tomkins P (2004) Filling in the ‘Neolithic background’: social life and social transformation in the Aegean before the Bronze Age. In: Barrett JC, Halstead P (eds) The emergence of civilization revisited, Sheffield studies in Aegean archaeology, vol 6. Oxbow Books, Oxford, pp 38–63

Tomkins P (2007) Neolithic: strata IX–VII, VII–VIB, VIA–V, IV, IIIB, IIIA, IIB, IIA and IC groups. In: Momigliano N (ed) Knossos pottery handbook: Neolithic and Bronze Age (Minoan), British school at Athens studies, vol 14. British School at Athens, London, pp 9–48

Tomkins P (2014) Tracing complexity in ‘the missing millennium’. An overview of recent research into the Final Neolithic period on Crete. In: Horejs B, Mehofer M (eds) Western Anatolia before Troy. Proto-Urbanisation in the 4th Millennium BC? Proceedings of the International Symposium held at the Kunsthistorisches Museum Wien, Vienna, Austria, 21–24 November, 2012. Austrian Academy of Sciences Press, Vienna, pp 345–364

Treuil R (1983) Le Néolitique et le Bronze Ancien Egéens. De Boccard, Paris

Vagnetti L (1972) L’insediamento neolitico di Festos. Annuario della Scuola Archeologica Italiana ad Atene 50-51:7–138

Vagnetti L, Belli P (1978) Characters and problems of the Final Neolithic in Crete. SMEA 19:125–163

Vagnetti L, Christopoulou A, Tzedakis I (1989) Saggi negli stati Neolitici. In: Tzedakis I, Sacconi A (eds) Scavi a Nerokourou, Kydonias. Edizioni sell’Ateneo, Roma, pp 9–97

van der Leeuw SE (1984) Dust to dust: a transformational view of the ceramic cycle. In: van der Leeuw SE, Pritchard AC (eds) The many dimension of pottery. Ceramics in archaeology and anthropology. University of Amsterdam, Amsterdam, pp 709–773

van der Marel HW, Beutelspacher H (1976) Atlas of infrared spectroscopy of clay minerals and their admixtures. Elsevier Scientific, Amsterdam

Watrous V, Hadzi-Vallianou D and Blitzer H (2004) The Plain of phaistos: Cycles of social complexity in the mesara region of crete. Monumenta Archaeologica 23. UCLA, Los Angeles

Warren P (1974) Crete, 3000-1400 B.C.: immigration and the archaeological evidence. In: Crossland RA, Birchall A (eds) Bronze Age migrations in the Aegean. Archaeological and linguistic problems in Greek prehistory. Noyes Press, Park Ridge, pp 41–47

Weinberg S (1965) The relative chronology of the Aegean in the stone and Early Bronze Ages. In: Ehrich R (ed) Chronologies in Old World archaeology. The University of Chicago Press, Chicago, pp 285–320

Weiner S (2010) Microarchaeology: beyond the visible archaeological record. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511811210

Wenger E (1998) Communities of practice: learning, meaning and identity. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511803932

Wilson DE (1985) The pottery and architecture of the EMIIA West Court House at Knossos. Annual of the British Schools at Athens 80:281–364. https://doi.org/10.1017/S0068245400007619

Wilson DE (2007) Early Prepalatial (EMI-EMII): EMI well, west court house, north-east magazines and south front groups. In: Momigliano N (ed) Knossos pottery handbook: Neolithic and Bronze Age (Minoan), British School at Athens Studies, vol 14. British School at Athens, London, pp 49–77

Wilson DE, Day PM (1994) Ceramic regionalism in Prepalatial Central Crete: the Mesara imports at EM I to EM II A Knossos. Annual of the British Schools at Athens 89:1–87. https://doi.org/10.1017/S006824540001529X

Wilson DE, Day PM (1999) EM IIB ware groups at Knossos: the 1907-08 south front tests. Annual of the British Schools at Athens 94:1–62. https://doi.org/10.1017/S0068245400000502

Wilson DE and Day PM (2000) EMI chronology and social practice: pottery from the early palace tests at Knossos. Annu Br Sch Athens 95:21–63

Whitbread IK (1989) A proposal for the systematic description of thin sections towards the study of the ancient ceramic technology. In: Maniatis Y, Fischer PM, Lodding ARE, Norén JG (eds) Archaeometry: proceedings of the 25th international symposium. Elsevier, Amsterdam, pp 127–138

Acknowledgements

This research was conducted as part of the project entitled ‘The Final Neolithic-Early Minoan transition in Phaistos, Crete: the contextual significance of continuity and change in pottery manufacture’ undertaken by Roberta Mentesana under the supervision of Peter M. Day, Roger Doonan, Vassilis Kilikoglou and Simona Todaro within the framework of the New Archaeological Research Network for Integrating Approaches to ancient material studies (NARNIA) Project. NARNIA is a Marie Curie Initial Training Network which is funded by the FP7 and the European Union (Grant agreement no. 265010). For access to study and sample the material discussed here, we are grateful to the late Prof. Vincenzo La Rosa and to Dr. Serena Di Tonto of the Italian Mission. The 23rd Ephorate of Prehistoric and Classical Antiquities kindly made arrangements for sampling and we are grateful to the Conservation Directorate of the Ministry of Culture for permission to sample and conduct analyses. The authors would like to acknowledge Noémi Müller, Maria Amenta, Anno Hein and Ioannis Karatasios of the Laboratory of Archaeological Materials at N.C.S.R. Demokritos (Athens) for their support in completing the analytical work of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mentesana, R., Kilikoglou, V., Todaro, S. et al. Reconstructing change in firing technology during the Final Neolithic–Early Bronze Age transition in Phaistos, Crete. Just the tip of the iceberg?. Archaeol Anthropol Sci 11, 871–894 (2019). https://doi.org/10.1007/s12520-017-0572-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12520-017-0572-8