Abstract

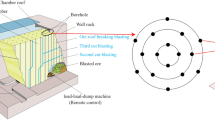

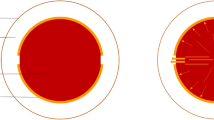

This paper adopts the red sandstone as blasting medium, studies the mechanism of rock breaking caused by slotted cartridge blasting, analyzes the crack distribution characteristics, sets up “rock-explosion crack” of three-dimensional reconstruction model, and accurately describes the explosion crack location and the shape of space distribution. The results show that there are only two cracks generated along the slotted direction of slotted cartridge blasting, and the crack position was symmetrical. Combining the calculation method of three-dimensional fracture fractal dimension with CT scanning, we quantitatively describe the evolution process of explosion fractures. The damage degree of rock after blasting with slotted cartridge was 56.5% lower than that of common charge. From the CT scan results and the numerical analysis, it can be concluded that slotted pipe causes plastic deformation, making the slotted pipe fit with blast-hole wall, and stress concentration occurs at the slotted pipe incision. The stress concentration intensity is greater than that in other areas, leading to the crack formation. Slotted cartridge initial crack formation location is at the joint of “slotted pipe incision and blast-hole wall.” It shows that the slotted cartridge can reduce the degree of damage caused by explosive, effectively protecting the damage caused by explosion to shaft wall.

Similar content being viewed by others

References

Boone MA, De KT, Bultreys T et al (2011) 3D mapping of water in oolithic limestone at atmospheric and vacuum saturation using X-ray micro-CT differential imaging. Mater Charact. 97:150–160

Chen HD, Cheng YP, Zhou HX et al (2013) Damage and permeability development in coal during unloading. Rock Mech Rock Eng. 46(6):1377–1390

Cho SH, Nakamura Y, Mohanty B (2008) Numerical study of fracture plane control in laboratory-scale blasting. Eng Fract Mech. 75:3966–3984

Cornish R, Mills JT (2001) Degradation mechanisms in shaped charge jet penetration. Int J Impact Eng. 26:105–114

Dewanckele J, De KT, Boone MA et al (2012) 4D imaging and quantification of pore structure modifications inside natural building stones by means of high resolution X-ray CT. Sci Total Environ. 416:436–448

Feng XT, Chen SL, Zhou H (2004) Real-time computerized tomography (CT) experiments on sandstone damage evolution during triaxial compression with chemical corrosion. Int J Rock Mech Min Sci. 41:181–192

Fourney WL, Dally JW, Holloway DC (1978) Controlled blasting with ligamented charge holders. Int J Rock Mech Min Sci. 15:121–129

Fourney WL, Barker DB, Holloway DC (1983) Model studies of well stimulation using propellant charges. Int J Rock Mech Min Sci. 20:91–101

Golab A, Ward CR, Permana A, Lennox P, Botha P (2013) High-resolution three-dimensional imaging of coal using microfocus X-ray computed tomography, with special reference to modes of mineral occurrence. Int J Coal Geol. 113:97–108

Guo DM, Liu K, Lu H, Yang R, Wang C, Wang Y (2016) Fracture behavior of an empty hole using the digital laser dynamic caustic method under directional controlled blasting. Mater Test 58:982–991

Jing Y, Armstrong RT, Mostaghimi P (2017) Impact of mineralization on digital coal properties. Energ Fuel. 31:58–68

Ju Y, Zheng JT, Epstein M, Sudak L, Wang J, Zhao X (2014) 3D numerical reconstruction of well-connected porous structure of rock using fractal algorithms. Comput Method Appl M. 279:212–226

Kawakata H, Cho A, Yanagidani T (2000) Gross structure of a fault during its formation process in Westerly granite. Techonophysics. 323:61–76

Liu CW, Xia BW, Lu YY et al (2018) Experimental study on quasi-static pressure of slot hydraulic blasting. Shock Vib. 67:1411–1421

Liu CW, Lu YY, Xia BW, Yu P (2019) Directional fracturing by slotting-blasting-caused stress wave form changes. Int J Impact Eng. 129:141–151

Mostaghimi P, Armstrong RT, Gerami A, Hu Y, Jing Y, Kamali F, Liu M, Liu Z, Lu X, Ramandi HL, Zamani A, Zhang Y (2017) Cleat-scale characterisation of coal: an overview. J Nat Gas Sci Eng. 39:143–160

Sok RM, Varslot T, Ghous A et al (2010) Pore scale characterization of carbonates at multiple scales: integration of Micro-CT, BSEM, and FIBSEM. Petrophysics. 51(6):379–387

Wang YB (2017) Study of the dynamic fracture effect using slotted cartridge decoupling charge blasting. Int J Rock Mech Min Sci. 96:34–46

Wang LB, Frost JD, Voyiadjis G et al (2003) Quantification of damage parameters using X-ray tomography images. Mech Mater. 35:777–790

Yang RS, Wang Y (2013) Experimental study of dynamic fracture effect of blasting crack in slotted cartridge decoupling charge blasting. Chin J Rock Mech Eng. 32:1337–1343 (in Chinese)

Yang RS, Wang Y (2017) Experimental research on the influence of an empty-hole defect on crack connections between a directionally fractured blast hole. J Test Eval. 45:2139–2150

Yang RS, Wang YB, Ding CX (2016a) Laboratory study of wave propagation due to explosion in a jointed medium. Int J Rock Mech Min Sci. 81:70–78

Yang SQ, Ju Y, Gao F et al (2016b) Strength, deformability and X-ray micro-CT observations of deeply buried marble under different confining pressures. Rock Mech Rock Eng. 49(11):27–44

Yang SQ, Ranjith PG, Jing HW, Tian WL, Ju Y (2017) An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatment. Geothermics. 65:180–197

Yang SQ, Yin PF, Huang YH, Cheng JL (2019) Strength, deformability and X-ray micro-CT observations of transversely isotropic composite rock under different confining pressures. Eng Fract Mech. 214:1–20

Yue ZW, Yang LY, Wang YB (2013) Experimental study of crack propagation in polymethyl methacrylate material with double holes under the directional controlled blasting. Fatigue Fract Eng M. 36:827–833

Yue ZW, Qiu P, Wang X et al (2016) Notched-borehole cut blasting study by the method of dynamic caustics. J China Coal Soc 41:858–863 (in Chinese)

Zhou XP, Zhang YX, Ha QL (2008) Real-time computerized tomography (CT) experiments on limestone damage evolution during unloading. Theor Appl Fract Mec. 50:49–56

Zhou HW, Zhong JC, Ren WG, Wang XY, Yi HY (2018) Characterization of pore-fracture networks and their evolution at various measurement scales in coal samples using X-ray mu CT and a fractal method. Int J Coal Geol. 189(2):35–49

Acknowledgements

The authors would like to thank the anonymous reviewers for their valuable and constructive comments.

Funding

This research is supported by the Project Funded by China Postdoctoral Science Foundation (No.2020TQ0032), the Key Projects of National Natural Science Foundation of China (NO.51934001), the Fundamental Research Funds for the Central Universities (FRF-TP-20-037A1), and the Interdisciplinary Research Project for Young Teachers of USTB (Fundamental Research Funds for the Central Universities) (FRF-IDRY-20-019).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Zuo, J., Yang, R., Min, G. et al. Studies on directional breaking controlled theory of slotted cartridge blasting for rock. Arab J Geosci 14, 1928 (2021). https://doi.org/10.1007/s12517-021-08334-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-08334-2