Abstract

Sweet sorghum syrups represent a renewable raw material that can be available year-round for production of biofuels and biochemicals. Sweet sorghum sugars have been used as sources for butanol production in the past but most often the studies focused on sweet sorghum juice and not on sweet sorghum syrups. Therefore, we investigated the feasibility of using the syrups as feedstock. Initial studies showed that diluted sweet sorghum syrups, to 60 g/L of glucose equivalents, could not be used as a direct replacement of a synthetic growth medium for industrial butanol-producing strain Clostridium beijerinckii. Further studies revealed that supplemental nutrients (most notably, ammonium–nitrogen) were required for successful fermentation. This was found true for two manufacturing sources of sweet sorghum syrups from commercial cultivars and hybrids. Typically, 15 g/L of total acetone, butanol, and ethanol were produced with approximately half of that being butanol. Some minor statistical difference was noted between the production potential of the two sources of syrup. However, aconitic acid, which was present at similar levels in both syrups, was ruled out as a butanol fermentation inhibitor at the fermentation pH > 4.5.

Similar content being viewed by others

References

Almodares, A., and M.R. Hadi. 2009. Production of bioethanol from sweet sorghum: A review. African Journal of Agricultural Research 4(9): 772–780.

Almodares, A., M. Ranjbar, and M.R. Hadi. 2010. Effects of nitrogen treatments and harvesting stages on the aconitic acid, invert sugar and fiber in sweet sorghum cultivars. Journal of Environmental Biology 31(6): 1001–1005.

Amorim, H.V. 2015. Challenges to produce ethanol from sweet sorghum in Brazil. Paper presented at the Sweet Sorghum Association 2015 Annual Conference, Orlando, FL, January 27–29.

Andrzejewski, B., G. Eggleston, S. Lingle, and R. Powell. 2013. Development of a sweet sorghum juice clarification method in the manufacture of industrial feedstocks for value-added fermentation products. Industrial Crops and Products 44: 77–87.

Badr, H.R., and M.K. Hamdy. 1992. Optimization of acetone-butanol production using response surface methodology. Biomass and Bioenergy 3(1): 49–55.

Cai, D., Y. Wang, C. Chen, P. Qin, Q. Miao, C. Zhang, P. Li, and T. Tan. 2016. Acetone-butanol-ethanol from sweet sorghum juice by an immobilized fermentation-gas stripping integration process. Bioresource Technology 211: 704–710.

Clarke, M.A., and M.A. Brannan. 1983. Rapid analyses of lactic acid, an indicator of sugar cane deterioration, and aconitic acid, an indicator of sugar cane maturity, by high performance liquid chromatography. Journal American Society of Sugar Cane Technologists 2: 88.

Collier, D.W. 1953. Concentration of aqueous aconitic acid solutions. U.S. Patent 2,650,248.

Day, D.F., and D. Sarkar. 1982. Fuel alcohol from sweet sorghum: Microbial aspects. Developments in Industrial Microbiology 23: 361–366.

Day, R.W., and G.P. Quinn. 1989. Comparisons of treatments after an analysis of variance in ecology. Ecological Monographs 59(4): 433–463.

Eggleston, G., B. Andrzejewski, M. Cole, C. Dalley, S. Sklanka, E. St Cyr, Y.J. Chung, and R. Powell. 2015. Novel storage technologies for raw and clarified syrup biomass feedstocks from sweet sorghum (Sorghum bicolor L. Moench). Biomass and Bioenergy 81: 424–436.

Eggleston, G., M. Heckemeyer, E.S. Cyr, and L. Wartelle. 2016. Case study: Commercialization of sweet sorghum juice clarification for large-scale syrup manufacture. Sugar Tech 18(3): 249–257.

Gibbons, W.R., and C.A. Westby. 1989. Cofermentation of sweet sorghum juice and grain for production of fuel ethanol and distillers’ wet grain. Biomass 18(1): 43–57.

Green, E.M. 2011. Fermentative production of butanol-the industrial perspective. Current Opinion in Biotechnology 22(3): 337–343.

Gump, B.H., B.W. Zoecklein, and K.C. Fugelsang. 2001. Prediction of prefermentation nutritional status of grape juice. In Food microbiology protocols, ed. J.F.T. Spencer and A.L. de Ragout Spencer, 283–296. Totowa, NJ: Humana Press.

Gump, B.H., B.W. Zoecklein, K.C. Fugelsang, and R.S. Whiton. 2002. Comparison of analytical methods for prediction of prefermentation nutritional status of grape juice. American Journal of Enology and Viticulture 53(4): 325–329.

Heckemeyer, M., G. Eggleston, and A.J. Heckemeyer. 2016. The new large-scale sweet sorghum industry in the USA. In Advances in sugar crop processing and conversion, ed. G. Eggleston and I.M. Lima, 33–43. New Orleans, LA: U.S. Department of Agriculture, Agricultural Research Service.

Hong, B., K.C. Shin, and L.T. Fan. 1982. Utilization of sugars in sorghum molasses by Clostridium acetobutylicum. In The twelfth annual biochemical engineering symposium, ed. L.E. Erickson and L.T. Fan, 104–111. Manhattan, KS: Kansas State University.

Jones, D.T., and D.R. Woods. 1986. Acetone-butanol fermentation revisited. Microbiological Reviews 50(4): 484–524.

Kanitkar, A., G. Aita, and L. Madsen. 2013. The recovery of polymerization grade aconitic acid from sugarcane molasses. Journal of Chemical Technology and Biotechnology 88(12): 2188–2192.

Keis, S., R. Shaheen, and D.T. Jones. 2001. Emended descriptions of Clostridium acetobutylicum and Clostridium beijerinckii, and descriptions of Clostridium saccharoperbutylacetonicum sp. nov. and Clostridium saccharobutylicum sp. nov. International Journal of Systematic and Evolutionary Microbiology 51(6): 2095–2103.

Khalil, S.R.A., A.A. Abdelhafez, and E.A.M. Amer. 2015. Evaluation of bioethanol production from juice and bagasse of some sweet sorghum varieties. Annals of Agricultural Sciences 60(2): 317–324.

Kim, M., and D.F. Day. 2011. Composition of sugar cane, energy cane, and sweet sorghum suitable for ethanol production at Louisiana sugar mills. Journal of Industrial Microbiology and Biotechnology 38(7): 803–807.

Kim, M., K.J. Han, Y. Jeong, and D.F. Day. 2012. Utilization of whole sweet sorghum containing juice, leaves, and bagasse for bio-ethanol production. Food Science and Biotechnology 21(4): 1075–1080.

Klasson, K.T. 2017. Impact of potential fermentation inhibitors present in sweet sorghum sugar solutions. Sugar Tech 17: 95–101.

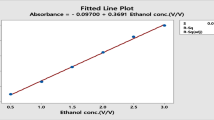

Klasson, K.T. 2018. The inhibitory effects of aconitic acid on bioethanol production. Sugar Tech 20(1): 88–94.

Montoya, G., J. Londono, P. Cortes, and O. Izquierdo. 2014. Quantitation of trans-aconitic acid in different stages of the sugar-manufacturing process. Journal of Agricultural and Food Chemistry 62(33): 8314–8318.

Nelson, E.K. 1929. Some organic acids of sugar cane molasses. Journal of the American Chemical Society 51(9): 2808–2810.

Polack, J.A., and D.F. Day. 1982. Ethanol from sweet sorghum. Journal American Society of Sugar Cane Technologists 1: 52–56.

Powell, R., J. Lindley, M. Radin, and S. Smith. 2016. Development of sweet sorghum as a feedstock crop. In Advances in sugar crop processing and conversion, ed. G. Eggleston and I.M. Lima, 127–133. New Orleans, LA: U.S. Department of Agriculture, Agricultural Research Service.

Prasad, S., A. Singh, N. Jain, and H.C. Joshi. 2007. Ethanol production from sweet sorghum syrup for utilization as automotive fuel in India. Energy & Fuels 21(4): 2415–2420.

Qureshi, N. 2014. Integrated bioprocessing and simultaneous product recovery for butanol production. In Biorefineries: Integrated biochemical processes for liquid biofuels, ed. Qureshi, N., D. Hodge and A. Vertes, 205–223. Amsterdam, Netherlands: Elsevier, Amsterdam, Netherlands.

Qureshi, N., and H.P. Blaschek. 1999. Butanol recovery from model solution/fermentation broth by pervaporation: Evaluation of membrane performance. Biomass and Bioenergy 17(2): 175–184.

Qureshi, N., S. Liu, S. Hughes, D. Palmquist, B. Dien, and B. Saha. 2016. Cellulosic butanol (ABE) biofuel production from sweet sorghum bagasse (SSB): Impact of hot water pretreatment and solid loadings on fermentation employing Clostridium beijerinckii P260. Bioenergy Research 9(4): 1167–1179.

Rochón, E., M.D. Ferrari, and C. Lareo. 2017. Integrated ABE fermentation-gas stripping process for enhanced butanol production from sugarcane-sweet sorghum juices. Biomass and Bioenergy 98: 153–160.

Serna-Saldivar, S.O., and W.L. Rooney. 2014. Production and supply logistics of sweet sorghum as an energy feedstock. In Sustainable bioenergy production, ed. L. Wang, 193–212. Boca Raton, FL: CRC Press.

Sirisantimethakom, L., L. Laopaiboon, P. Sanchanda, J. Chatleudmongkol, and P. Laopaiboon. 2016. Improvement of butanol production from sweet sorghum juice by Clostridium beijerinckii using an orthogonal array design. Industrial Crops and Products 79: 287–294.

Tomlins, K.I., D.M. Baker, and I.J. McDowell. 1990. HPLC method for the analysis of organic acids, sugars, and alcohol in extracts of fermenting cocoa beans. Chromatographia 29(11–12): 557–561.

Ventre, E.K. 1955. Method for extracting aconitic acid from sugarcane and sorgo juices, sirups, and molasses. U.S. Patent 2,712,552.

Ventre, E.K., J.A. Ambler, H.C. Henry, S. Byall, and H.S. Paine. 1946. Extraction of aconitic acid from sorgo. Industrial and Engineering Chemistry 38(2): 201–204.

Visioli, L.J., E.A. Alves, A. Trindade, R.C. Kuhn, M. Schwaab, and M.A. Mazutti. 2015. Evaluation of biobutanol production by Clostridium beijerinckii NRRL B-592 using sweet sorghum as carbon source. Ciencia Rural 45(9): 1707–1712.

Wu, X., S. Staggenborg, J.L. Propheter, W.L. Rooney, J. Yu, and D. Wang. 2010. Features of sweet sorghum juice and their performance in ethanol fermentation. Industrial Crops and Products 31(1): 164–170.

Xue, C., G.Q. Du, J.X. Sun, L.J. Chen, S.S. Gao, M.L. Yu, S.T. Yang, and F.W. Bai. 2014. Characterization of gas stripping and its integration with acetone-butanol-ethanol fermentation for high-efficient butanol production and recovery. Biochemical Engineering Journal 83: 55–61.

Yu, J., T. Zhang, J. Zhong, X. Zhang, and T. Tan. 2012. Biorefinery of sweet sorghum stem. Biotechnology Advances 30(4): 811–816.

Acknowledgements

The authors would like to thank Mr. Larry Boihem, Jr., for assistance with chemical analysis and Dr. Maureen Wright and Ms. Alexa Triplett for collecting sweet sorghum syrup samples. Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.

Funding

This study was funded by internal research funds for Project 6054-41000-110-00-D of the U.S. Department of Agriculture, Agricultural Research Service, under the National Program: Quality and Utilization of Agricultural Products (NP306).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Klasson, K.T., Qureshi, N., Powell, R. et al. Fermentation of Sweet Sorghum Syrup to Butanol in the Presence of Natural Nutrients and Inhibitors. Sugar Tech 20, 224–234 (2018). https://doi.org/10.1007/s12355-018-0594-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-018-0594-2