Abstract

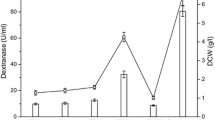

Dextran causes negative impact on the normal production of sugar industry. Traditional removal methods have many disadvantages. 6-alpha-d-glucan-6-glucanohydrolase (EC 3.2.1.11) from Chaetomium gracile without food safety concern could remove dextran, but it has low level of enzyme production. The present study aimed to improve α-dextranase activity to meet industry demand. Consequently, α-dextranase activity reached 242.8 U/mL when fermentation condition was 29 °C, pH 6.0 and 220 rpm. Meanwhile, ten glass beads were added to fermentation medium when fermentation time was 12 h, which improved enzyme activity by 135.5% with the highest activity. Purified α-dextranase exhibited excellent thermal stability and surfactants tolerance. α-Dextranase from C. gracile could remove dextran by 46.6% in mixed sugarcane juice and 14.1% in clarified sugarcane juice. It had similar dextran removal efficiency with commercial enzymes. These evaluations showed that α-dextranase had great potential in removing dextran in sugar industry.

Similar content being viewed by others

References

Abdel-Naby, M.A., A.-M.S. Ismail, A.M. Abdel-Fattah, and A.F. Abdel-Fattah. 1999. Preparation and some properties of immobilized Penicillium funiculosum 258 dextranase. Process Biochemistry 34: 391–398.

Ali, M.S., C.C. Yun, A.L. Chor, R.N. Rahman, M. Basri, and A.B. Salleh. 2012. Purification and characterisation of an F16L mutant of a thermostable lipase. Protein Journal 31: 229–237.

Amorim, R.V.S., E.S. Melo, M.G. Carneiro-da-Cunha, W.M. Ledingham, and G.M. Campos-Takaki. 2003. Chitosan from Syncephalastrum racemosum used as a film support for lipase immobilization. Bioresoure Technology 89: 35–39.

Bashari, M., Z.Y. Jin, J.P. Wang, and X.B. Zhan. 2016. A novel technique to improve the biodegradation efficiency of dextranase enzyme using the synergistic effects of ultrasound combined with microwave shock. Innovative Food Science & Emerging Technologies 35: 125–132.

Boil, P.G.M.D. 1997. Refined sugar and floc formation. A survey of the literature. International Sugar Journal 99: 310–314.

Chen, L., X.S. Zhou, W.M. Fan, and Y.X. Zhang. 2008. Expression, purification and characterization of a recombinant Lipomyces starkey dextranase in Pichia pastoris. Protein Expression and Purification 58: 87–93.

Cheng, N., K. Koda, Y. Tamai, Y. Yamamoto, T.E. Takasuka, and Y. Uraki. 2017. Optimization of simultaneous saccharification and fermentation conditions with amphipathic lignin derivatives for concentrated bioethanol production. Bioresoure Technology 232: 126–132.

Deng, L., J.M. Qin, X.P. Jia, and X. Guo. 2017. Enhanced thermoelectric performance of skutterudites via orthogonal experimental design. Journal of Alloys and Compounds 695: 3152–3155.

Eggleston, G., and A. Monge. 2005. Optimization of sugarcane factory application of commercial dextranases. Process Biochemistry 40: 1881–1894.

Franssen, O., O.P. Vos, and W.E. Hennink. 1997. Delayed release of a model protein from enzymatically-degrading dextran hydrogels. Journal of Controlled Release 44: 237–245.

Fukumoto, J., H. Tsuji, and D. Tsuru. 1971. Studies on mold dextranases. I. Penicillium luteum dextranase: Its production and some enzymatic properties. Journal of Biochemistry 69: 1113–1121.

Hayacibara, M.F., H. Koo, A.M. Vacca Smith, L.K. Kopec, K. Scott-Anne, J.A. Cury, and W.H. Bowen. 2004. The influence of mutanase and dextranase on the production and structure of glucans synthesized by streptococcal glucosyltransferases. Carbohydrate Research 339: 2127–2137.

Hoang, N.X., S. Ferng, C.-H. Ting, W.-H. Huang, R.Y.-Y. Chiou, and C.-K. Hsu. 2016. Optimizing the initial moromi fermentation conditions to improve the quality of soy sauce. LWT-Food Science and Technology 74: 242–250.

Holman, B.W.B., S.M. Fowler, and D.L. Hopkins. 2016. Are shear force methods adequately reported? Meat Science 119: 1–6.

Jiménez, E.R. 2009. Dextranase in sugar industry: A review. Sugar Tech 11: 124–134.

Khalikova, E., P. Susi, and T. Korpela. 2005. Microbial dextran-hydrolyzing enzymes: Fundamentals and applications. Microbiology and Molecular Biology Reviews 69: 306–325.

Li, K., H. Lu, F. Hang, S. Li, and J. Liu. 2016. Improved dextranase production by Chaetomium gracile through optimization of carbon source and fermentation parameters. Sugar Tech 19: 432–437. doi:10.1007/s12355-016-0476-4.

Nikhil, U.N., A.D. Carl, and H. Zhao. 2010. Engineering of enzymes for selective catalysis. Current Organic Chemistry 14: 1870–1882.

Patil, S.S., A. Kar, and D. Mohapatra. 2016. Stabilization of rice bran using microwave: Process optimization and storage studies. Food and Bioproducts Processing 99: 204–211.

Purushe, S., D. Prakash, N.N. Nawani, P. Dhakephalkar, and B. Kapadnis. 2012. Biocatalytic potential of an alkalophilic and thermophilic dextranase as a remedial measure for dextran removal during sugar manufacture. Bioresoure Technology 115: 2–7.

Robyt, J.F., and S.H. Eklund. 1982. Stereochemistry involved in the mechanism of action of dextransucrase in the synthesis of dextran and the formation of acceptor products. Bioorganic Chemistry 11: 115–132.

Virgen-Ortíz, J.J., V. Ibarra-Junquera, P. Escalante-Minakata, J.D.J. Ornelas-Paz, J.A. Osuna-Castro, and A. González-Potes. 2015. Kinetics and thermodynamic of the purified dextranase from Chaetomium erraticum. Journal of Molecular Catalysis. B, Enzymatic 122: 80–86.

Wang, D., M.S. Lu, S.J. Wang, Y.L. Jiao, W.J. Li, Q. Zhu, and J.P. Liu. 2014. Purification and characterization of a novel marine Arthrobacter oxydans KQ11 dextranase. Carbohydrate Polymers 106: 71–76.

Wynter, C.V.A., M. Chang, J. De, B. Jersey, P.A.Inkerman Patel, and S. Hamilton. 1997. Isolation and characterization of a thermostable dextranase. Enzyme and Microbial Technology 20: 242–247.

Zhang, Z.D., D.M. Lan, P.F. Zhou, J. Li, B. Yang, and Y. Wang. 2017. Control of sticky deposits in wastepaper recycling with thermophilic esterase. Cellulose 24: 1–11.

Zhang, Z.D., J.D. Liu, H.Q. Lu, F.X. Hang, C.R. Shi, and K. Li. 2015. Study on the improvement effect of low- frequency ultrasonic on the production of α-dextranase in Chaetomium gracile. Science and Technology of Food Industry 5: 234–241.

Zohra, R.R., A. Aman, R.R. Zohra, A. Ansari, M. Ghani, and S.A.U. Qader. 2013. Dextranase: Hyper production of dextran degrading enzyme from newly isolated strain of Bacillus licheniformis. Carbohydrate Polymers 92: 2149–2153.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (31460026, 31560027) and Guangxi Science and Technology Development Program (Grant No. 14122003-6).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no conflicts of interest regarding this paper.

Rights and permissions

About this article

Cite this article

Zhang, Z., Liu, J., Ma, S. et al. Enhancement of Catalytic Performance of α-dextranase from Chaetomium gracile Through Optimization and Suitable Shear Force. Sugar Tech 20, 78–87 (2018). https://doi.org/10.1007/s12355-017-0540-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-017-0540-8