Abstract

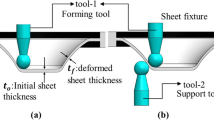

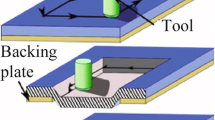

Incremental Sheet Forming (ISF) has been developed as a flexible manufacturing technology for small batch production and prototyping. ISF can also be used to form additional features or stiffening elements such as hole flanges. Incremental Hole Flanging (IHF) operations seem to be a promising alternative to conventional hole flanging. If it was possible to exploit the extended formability of ISF while achieving accuracy and process times of conventional hole flanging, IHF could substitute conventional flanging operations in many cases. However, the long process times and limited geometrical accuracy hinder industrial take-up. In this work, two different tooling concepts which allow incremental hole flanging operations at high speeds are investigated. The first tool is designed as a single forming tool that offers high flexibility and a comparison to conventional Incremental Hole Flanging. The second tool consists of four forming tools to improve the geometrical accuracy of hole flanges. In order to achieve high speeds, the experimental setup is installed on a turning machine. Compared to hole flanging with a conventional CNC machine, the forming time to expand a hole from 50 mm to 100 mm could be reduced from 1680 s to 15.7 s. The geometrical accuracy of the parts formed with the second tool concept could be improved significantly (up to 3 times regarding to the mean surface deviation to at maximum speed). Furthermore, it is shown that forming at high speeds has no significant influence on the characteristics of sheet thickness, strain, forces or geometrical accuracy.

Similar content being viewed by others

References

Cui Z, Gao L (2010) Studies on hole-flanging process using multistage incremental forming. In CIRP Journal of Manufacturing Science and Technology:124–128. doi:10.1016/j.cirpj.2010.02.001

Ambrogio G, Filice L, Gagliardi F (2011) Enhancing incremental sheet forming performance using high speed. In Key Engineering Materials 473:847–852. doi:10.4028/www.scientific.net/KEM.473.847

Kwiatkowski L et al (2009) Tooling concepts to speed up incremental sheet forming. In Production Engineering Research and Development 4:57–64

Ambrogio G et al (2014) Analysis of energy efficiency of different setups able to perform single point incremental forming (SPIF) processes. In Procedia CIRP 15:111–116

Hamilton K, Jeswiet J (2010) Single point incremental forming at high feed rates and rotational speeds: surface and structural consequences. In CIRP Annals -Manufacturing Technology 59:311–314. doi:10.1016/j.cirp.2010.03.016

Ambrogio G, Filice L, Gagliardi F (2012) Improving industrial suitability of incremental sheet forming process. In The International Journal of Advanced Manufacturing Technology 58:941–947. doi:10.1007/s00170-011-3448-6

Borrego M, Morales-Palma D (2016) Experimental study of hole-flanging by single-stage incremental sheet forming. J Mater Process Technol. doi:10.1016/j.jmatprotec.2016.06.026

Bambach M, Voswinckel H (2014) A new process for performing hole-flanging operations by incremental sheet forming. Procedia Engineering. doi:10.1016/j.proeng.2014.10.325

Brecher C, Özdemir D. (2017) Multi-technology platforms (MTPs). Integrative Production Technology 369–513. doi: 10.1007/978-3-319-47452-6_6

Voswinckel H, Bambach H (2014) Improving geometrical accuracy for flanging by incremental sheet metal forming. Int J Mater Form. doi:10.1007/s12289-014-1182-y

Acknowledgements

The authors would like to thank the German Research Foundation DFG for the kind support within the Cluster of Excellence “Integrative Production Technology for High-Wage Countries”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by German Research Foundation DFG within the Cluster of Excellence “Integrative Production Technology for High-Wage Countries” (EXC128).

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Laugwitz, M., Voswinckel, H., Hirt, G. et al. Development of tooling concepts to increase geometrical accuracy in high speed incremental hole flanging. Int J Mater Form 11, 471–477 (2018). https://doi.org/10.1007/s12289-017-1356-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-017-1356-5