Abstract

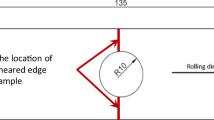

Edge cracking is one of the common failures during the stamping of Advanced High Strength Steel(AHSS). The limit strains of the edge are hard to predict by traditional methods because edge formability is influenced by many factors such as edge quality, process parameters, material properties and so on. Hole expansion tests are conducted with DP780 under three hole diameters and two punching clearances to investigate the effects of curvature and pre-damage caused by punching on edge stretchability. The corresponding simulations are carried out meanwhile with a new model based on Marciniak and Kuczynski (M-K) model and Hill’s localized necking theory to predict the edge limit strain. This new model is proposed for the hole edge with pre-damage and improves the predictability of edge cracking in hole-expansion simulation. The problem that the traditional ideal model fails to predict the hole expansion ratio (HER) of pre-damage edge is also successfully solved by the new model with the use of the Damage Zone and Effective Failure Strain Ratio (EFSR). The comparison between the experiments and simulations reveals that this new model can be used in edge forming failure prediction of AHSS.

Similar content being viewed by others

References

Zhang Y, Lai X, Zhu P, Wang W (2006) Lightweight design of automobile component using high strength steel based on dent resistance. Mater Des 27(1):64–68

Kleiner M, Geiger M, Klaus A (2003) Manufacturing of lightweight components by metal forming. CIRP Ann Manuf Technol 52(2):521–542

Levy B, Van Tyne C (2008) Failure during sheared edge stretching. J Mater Eng Perform 17(6):842–848

Zhou D, Du C, Siekirk J, McGuire J, Chen X, Levy BS (2010) A practical failure limit for sheared edge stretching of automotive body panels. SAE Technical Paper

Konieczny A, Henderson T (2007) On formability limitations in stamping involving sheared edge stretching. SAE Technical Paper

Cockcroft M, Latham D (1968) Ductility and the workability of metals. J Inst Met 96(1):33–39

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields∗. J Mech Phys Solids 17(3):201–217

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35(2):363–371

Golovashchenko SF (2006) A study on trimming of aluminum autobody sheet and development of a new robust process eliminating burrs and slivers. Int J Mech Sci 48(12):1384–1400

Chen X, Shi MF, Shih H-C, Luo M, Wierzbicki T (2010) AHSS shear fracture predictions based on a recently developed fracture criterion. SAE technical paper,

Zhu H, Zhu X (2011) A Mixed-mode fracture criterion for AHSS cracking prediction at large strain. SAE Technical Paper

12. Chen G, Shi MF, Tyan T (2011) Fracture modeling of AHSS in component crush tests. SAE Technical Paper

Uthaisangsuk V, Prahl U, Bleck W (2009) Stretch-flangeability characterisation of multiphase steel using a microstructure based failure modelling. Comput Mater Sci 45(3):617–623

Marciniak Z, Kuczyński K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9(9):609–620

Hill R (1952) On discontinuous plastic states, with special reference to localized necking in thin sheets. J Mech Phys Solids 1(1):19–30

Mori K-I, Abe Y, Suzui Y (2010) Improvement of stretch flangeability of ultra high strength steel sheet by smoothing of sheared edge. J Mater Process Technol 210(4):653–659

Acknowledgments

The authors would like to thank financial support from National Natural Science Foundation of China (51105246).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, C., Chen, J., Xia, C. et al. Study of curvature and pre-damage effects on the edge stretchability of advanced high strength steel based on a new simulation model. Int J Mater Form 9, 269–276 (2016). https://doi.org/10.1007/s12289-014-1197-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-014-1197-4