Abstract

This study deals with different tool surface description methods used in the finite element analysis of sheet metal forming processes. The description of arbitrarily-shaped tool surfaces using the traditional linear finite elements is compared with two distinct smooth surface description approaches: (i) Bézier patches obtained from the Computer-Aided Design model and (ii) smoothing the finite element mesh using Nagata patches. The contact search algorithm is presented for each approach, exploiting its special features in order to ensure an accurate and efficient contact detection. The influence of the tool modelling accuracy on the numerical results is analysed using two sheet forming examples, the unconstrained cylindrical bending and the reverse deep drawing of a cylindrical cup. Smoothing the contact surfaces with Nagata patches allows creating more accurate tool models, both in terms of shape and normal vectors, when compared with the conventional linear finite element mesh. The computational efficiency is evaluated in this study through the total number of increments and the required CPU time. The mesh refinement in the faceted description approach is not effective in terms of computational efficiency due to large discontinuities in the normal vector field across facets, even when adopting fine meshes.

Similar content being viewed by others

References

Tekkaya AE (2000) State-of-the-art of simulation of sheet metal forming. J Mater Process Technol 103:14–22. doi:10.1016/S0924-0136(00)00413-1

Makinouchi A (1996) Sheet metal forming simulation in industry. J Mater Process Technol 60:19–26. doi:10.1016/0924-0136(96)02303-5

Gantar G, Pepelnjak T, Kuzman K (2002) Optimization of sheet metal forming processes by the use of numerical simulations. J Mater Process Technol 130–131:54–59. doi:10.1016/S0924-0136(02)00786-0

Chenot J-L, Fourment L, Mocellin K (2002) Numerical treatment of contact and friction in FE simulation of forming processes. J Mater Process Technol 125–126:45–52. doi:10.1016/S0924-0136(02)00416-8

Yoshida F, Uemori T (2002) A model of large-strain cyclic plasticity describing the Bauschinger effect and workhardening stagnation. Int J Plast 18:661–686. doi:10.1016/S0749-6419(01)00050-X

de Sousa RJ A, Cardoso RPR, Valente RAF, Yoon J-W, Grácio JJ, Natal Jorge RM (2005) A new one-point quadrature enhanced assumed strain (EAS) solid-shell element with multiple integration points along thickness: Part I–geometrically linear applications. Int J Numer Methods Eng 62:952–977. doi:10.1002/nme.1226

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194:4135–4195. doi:10.1016/j.cma.2004.10.008

Cazacu O, Barlat F (2001) Generalization of Drucker’s yield criterion to orthotropy. Math Mech Solids 6:613–630. doi:10.1177/108128650100600603

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi S-H, Chu E (2003) Plane stress yield function for aluminum alloy sheets–part 1: theory. Int J Plast 19:1297–1319. doi:10.1016/S0749-6419(02)00019-0

Menezes LF, Teodosiu C (2000) Three-dimensional numerical simulation of the deep-drawing process using solid finite elements. J Mater Process Technol 97:100–106. doi:10.1016/S0924-0136(99)00345-3

Yang DY, Yoo DJ, Song IS, Lee JH (1995) Investigation into tool surface description for finite element analysis of three-dimensional sheet metal forming process. J Mater Process Technol 45:267–273. http://dx.doi.org/10.1016/0924-0136(94)90351-4

Santos A, Makinouchi A (1995) Contact Strategies to deal with different tool descriptions in static explicit FEM of 3-D sheet metal forming simulation, J Mater Process Technol 50:277–291. http://dx.doi.org/10.1016/0924-0136(94)01391-D

Hama T, Nagata T, Teodosiu C, Makinouchi A, Takuda H (2008) Finite-element simulation of springback in sheet metal forming using local interpolation for tool surfaces. Int J Mech Sci 50:175–192. http://dx.doi.org/10.1016/j.ijmecsci.2007.07.005

Hachani M, Fourment L (2013) A smoothing procedure based on quasi-C1 interpolation for 3D contact mechanics with applications to metal forming. Comput Struct 128:1–13. doi:10.1016/j.compstruc.2013.05.008

Shim HB, Suh EK (2000) Contact treatment algorithm for the trimmed NURBS surface. J Mater Process Technol 104:200–206. http://dx.doi.org/10.1016/S0924-0136(00)00555-0

Zhu X-F, Hu P, Ma Z-D, Zhang X, Li W, Bao J, Liu M (2013) A new surface parameterization method based on one-step inverse forming for isogeometric analysis-suited geometry. Int J Adv Manuf Technol 65:1215–1227. http://dx.doi.org/10.1007/s00170-012-4251-8.

Stadler M, Holzapfel GA, Korelc J (2003) Cn continuous modelling of smooth contact surfaces using NURBS and application to 2D problems. Int J Numer Methods Eng 57:2177–2203. http://dx.doi.org/10.1002/nme.776.

Krstulovic-Opara L, Wriggers P, Korelc J (2002) A C1-continuous formulation for 3D finite deformation friction contact. Comput Mech 29:27–42. http://dx.doi.org/10.1007/s00466-002-0317-z.

Puso MA, Laursen TA (2002) A 3D contact smoothing method using Gregory patches. Int J Numer Methods Eng 54:1161–1194. http://dx.doi.org/10.1002/nme.466.

McDevitt TW, Laursen TA (2000) A mortar-finite element formulation for frictional contact problems. Int J Numer Methods Eng 48:1525–1547. http://dx.doi.org/10.1002/1097-0207(20000810)48:10<1525::AID-NME953>3.0.CO;2-Y doi:10.1002/1097-0207(20000810)48:10%3c1525::AID-NME953%3e3.0.CO;2-Y .

Puso MA, Laursen TA (2004) A mortar segment-to-segment contact method for large deformation solid mechanics. Comput Method Appl Mech Eng 193:601–629. http://dx.doi.org/10.1016/j.cma.2003.10.010.

Puso MA, Laursen TA (2004) A mortar segment-to-segment frictional contact method for large deformations. Comput Method Appl Mech Eng 193:4891–4913. http://dx.doi.org/10.1016/j.cma.2004.06.001.

Temizer I, Wriggers P, Hughes TJR (2012) Three-dimensional mortar-based frictional contact treatment in isogeometric analysis with NURBS. Comput Method Appl Mech Eng 209–212:115–128. http://dx.doi.org/10.1016/j.cma.2011.10.014.

Alart P, Curnier A (1991) A mixed formulation for frictional contact problems prone to Newton like solution methods. Comput Methods Appl Mech Engrg 92:353–375. http://dx.doi.org/10.1016/0045-7825(91)90022-X.

Menezes LF, Neto DM, Oliveira MC, Alves JL (2011) Improving computational performance through HPC techniques: case study using DD3IMP in-house code. AIP Conf Proc 1353:1220–1225. http://dx.doi.org/10.1063/1.3589683.

Oliveira MC, Alves JL, Menezes LF (2003) Improvement of a frictional contact algorithm for strongly curved contact problems. Int J Numer Methods Eng 58:2083–2101. http://dx.doi.org/10.1002/nme.845.

Piegl L, Tiller W (1997) The NURBS book. Springer, New York

Farin G (1997) Curves and surfaces for computer-aided geometric design: a practical guide. Academic, London

Neto DM, Oliveira MC, Menezes LF, Alves JL (2014). Applying Nagata patches to smooth discretized surfaces used in 3D frictional contact problems. Comput Method Appl Mech Eng 271:296–320. http://dx.doi.org/10.1016/j.cma.2013.12.008.

Nagata T (2005) Simple local interpolation of surfaces using normal vectors. Comput Aided Geom Des 22:327–347. http://dx.doi.org/10.1016/j.cagd.2005.01.004.

Neto DM, Oliveira MC, Menezes LF, Alves JL (2013) Nagata patch interpolation using surface normal vectors evaluated from the IGES file. Finite Elem Anal Des 72:35–46. http://dx.doi.org/10.1016/j.finel.2013.03.004.

Neto DM, Oliveira MC, Menezes LF, Alves JL (2013) Improving Nagata patch interpolation applied for tool surface description in sheet metal forming simulation. Comput-Aided Des 45:639–656. http://dx.doi.org/10.1016/j.cad.2012.10.046.

Zhong ZH, Nilsson L (1989) A contact searching algorithm for general contact problems. Comput Struct 33:197–209. http://dx.doi.org/10.1016/0045-7949(89)90141-7.

Benson DJ, Hallquist JO (1990) A single surface contact algorithm for the post-buckling analysis of shell structures. Comput Methods Appl Mech Engrg 78:141–163. http://dx.doi.org/10.1016/0045-7825(90)90098-7.

Yastrebov VA, Cailletaud G, Feyel F (2011) A local contact detection technique for very large contact and self-contact problems: sequential and parallel implementations. Trends in computational contact mechanics, LNACM, 58:227–251. http://dx.doi.org/10.1007/978-3-642-22167-5_13.

Wriggers P (1995) Finite element algorithms for contact problems. Arch Comput Method Eng 2:1–49. http://dx.doi.org/10.1007/BF02736195.

Konyukhov A, Schweizerhof K (2008) On the solvability of closest point projection procedures in contact analysis: analysis and solution strategy for surfaces of arbitrary geometry. Comput Methods Appl Mech Engrg 197:3045–3056. http://dx.doi.org/10.1016/j.cma.2008.02.009.

Heege A, Alart P (1996) A frictional contact element for strongly curved contact problems. Int J Numer Methods Engrg 39:165–184. http://dx.doi.org/10.1002/(SICI)1097-0207(19960115)39:1<165::AID-NME846>3.0.CO;2-Y doi:10.1002/(SICI)1097-0207(19960115)39:1%3c165::AID-NME846%3e3.0.CO;2-Y .

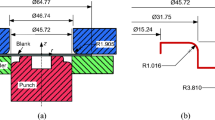

Yang DY, Oh SI, Huh H, Kim YH (2002) Benchmark test B: unconstrained cylindrical bending. In: Yang DY, Oh SI, Huh H, Kim YH (eds) Proceedings of the 5th International Conference and Workshop on Numerical Simulation of 3D Sheet Forming Processes, vol 2. Jeju Island, South Korea, pp 757–811

Gelin JC, Picart P (1999) Benchmark C: reverse deep drawing of a cylindrical cup. In: Gelin JC, Picart P (eds) Proceedings of Numisheet’99. Besançon, France, pp 871–932

Oliveira MC, Menezes LF (2004) Automatic correction of the time step in implicit simulations of the stamping process. Finite Elem Anal Des 40:1995–2010. http://dx.doi.org/10.1016/j.finel.2004.01.009.

Yamada Y, Yoshimura N (1968) Plastic stress–strain matrix and its application for the solution of elastic–plastic problems by the finite element method. Int J Mech Sci 10:343–354. http://dx.doi.org/10.1016/0020-7403(68)90001-5.

Thuillier S, Manach PY, Menezes LF, Oliveira MC (2002) Experimental and numerical study of reverse re-drawing of anisotropic sheet metals. J Mater Process Technol 125–126:764–771. http://dx.doi.org/10.1016/S0924-0136(02)00387-4.

Neto DM, Oliveira MC, Alves JL, Menezes LF (2014) Influence of the plastic anisotropy modelling in the reverse deep drawing process simulation. Mater Des 60:368–379. http://dx.doi.org/10.1016/j.matdes.2014.04.008.

Acknowledgements

The authors gratefully acknowledge the financial support of the Portuguese Foundation for Science and Technology (FCT) via the projects PTDC/EME-TME/118420/2010 and PEst-C/EME/UI0285/2013 and by FEDER funds through the program COMPETE – Programa Operacional Factores de Competitividade, under the project CENTRO-07-0224-FEDER-002001 (MT4MOBI). The first author is also grateful to the FCT for the PhD grant SFRH/BD/69140/2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neto, D.M., Oliveira, M.C., Alves, J.L. et al. Comparing faceted and smoothed tool surface descriptions in sheet metal forming simulation. Int J Mater Form 8, 549–565 (2015). https://doi.org/10.1007/s12289-014-1177-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-014-1177-8