Abstract

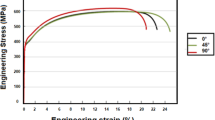

The Forming Limit Diagram (FLD) is a useful method for characterizing the formability of sheet metals. In this paper, different numerical models were used to investigate the FLD of Tailor Welded Blanks (TWB). TWB were CO2 laser-welded of interstitial-free (IF) steel sheets with difference in thickness. Numerical approaches of Müschenborn-Sonne Forming Limit Diagram (MSFLD), Forming Limit Diagram criterion (FLDcrt) and Ductile Fracture Criterion (DFCcrt), as well as new numerical method of Second Derivative of Thinning (SDT) were used for FLD prediction. The results of numerical models were compared with the experimental FLD, Limit Dome Height (LDH) and also load–displacement of samples. The emphasis of this investigation is to determine the performance of these different approaches in predicting the FLD. Results show that previous approaches are successful for the left side of FLD (drawing), but not so successful for the right side of the FLD (stretching). Influence of anisotropy on the forming behavior of TWB is investigated in this study and its results are compared with isotropic models and experimental data.

Similar content being viewed by others

References

Han HN, Kim K-H (2003) A ductile fracture criterion in sheet metal forming process. J Mater Process Technol 142(1):231–238

Keeler SP, Backofen WA (1963) Plastic instability and fracture in sheets stretched over rigid punches. Trans ASM 56:25–98

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in the press shop. SAE Technical Paper:Paper No.680093

Jain M, Allin J, Lloyd DJ (1999) Fracture limit prediction using ductile fracture criteria for forming of an automotive aluminum sheet. Int J Mech Sci 41(10):1273–1288. doi:10.1016/S0020-7403(98)00070-8

Ozturk F, Lee D (2004) Analysis of forming limits using ductile fracture criteria. J Mater Process Technol 147(3):397–404. doi:10.1016/j.jmatprotec.2004.01.014

Sheng ZQ (2008) Formability of tailor-welded strips and progressive forming test. J Mater Process Technol 205(1–3):81–88. doi:10.1016/j.jmatprotec.2007.11.108

Shi MF, Pickett KM, Bhatt KK (1993) Formability issues in the application of tailor welded blank sheets. SAE, New York

Chien WY, Pan J, Tang SC (2004) A combined necking and shear localization analysis for aluminum sheets under biaxial stretching conditions. Int J Plast 20(11):1953–1981. doi:10.1016/j.ijplas.2003.08.006

Chan LC, Chan SM, Cheng CH, Lee TC (2005) Formability and weld zone analysis of tailor-welded blanks for various thickness ratios. J Eng Mater Technol 127(2):179–185. doi:10.1115/1.1857936

Safdarian Korouyeh R, Moslemi Naeini H, Liaghat G (2012) Forming limit diagram prediction of tailor-welded blank using experimental and numerical methods. J Materi Eng Perform 21(10):2053–2061. doi:10.1007/s11665-012-0156-9

Safdarian Korouyeh R, Moslemi Naeini H, Torkamany MJ, Liaghat G (2013) Experimental and theoretical investigation of thickness ratio effect on the formability of tailor welded blank. Optics Laser Technol 51(0):24–31. doi:10.1016/j.optlastec.2013.02.016

Müschenborn W, Sonne H (1975) Influence of the strain path on the forming limits of sheet metal. Arch fur das Eisenhüttenwesen 46(2):597–602

(ASTM) ASfTaM (1999) Metals Test Methods and Analytical Procedures

Brun R, Chambard A, Lai M, De Luca P (1999) Actual and virtual testing techniques for a numerical definition of materials. In: Numisheet International Conference. BURS, pp 393–400

Panda SK, Kumar DR, Kumar H, Nath AK (2007) Characterization of tensile properties of tailor welded IF steel sheets and their formability in stretch forming. J Mater Process Technol 183(2–3):321–332. doi:10.1016/j.jmatprotec.2006.10.035

He S, Wu X, Hu SJ (2003) Formability enhancement for tailor-welded blanks using blank holding force control. J Manuf Sci Eng 125(3):461–467. doi:10.1115/1.1580853

Saunders FI, Wagoner RH (1996) Forming of tailor-welded blanks. Metall Mater Trans A 27(9):2605–2616. doi:10.1007/bf02652354

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc Royal Soc Lond Ser A Math Phys Sci 193(1033):281–297. doi:10.1098/rspa.1948.0045

Hecker SS (1974) A cup test for assessing stretchability. Met Eng 14:30–36

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Safdarian, R., Jorge, R.M.N., Santos, A.D. et al. A comparative study of forming limit diagram prediction of tailor welded blanks. Int J Mater Form 8, 293–304 (2015). https://doi.org/10.1007/s12289-014-1168-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-014-1168-9