Abstract

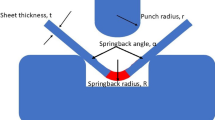

The current work involves both modeling and optimization approaches to achieve minimum spring-back in V-die bending process of heat treated CK67 sheets. Number of 36 experimental tests have been conducted with various levels of sheet orientation, punch tip radius and sheet thickness. Firstly, various predictive models based on statistical analysis, back-propagation neural network (BPNN), counter propagation neural network (CPNN) and radial basis function network (RBFNN) have been developed using experimental observations. Then the accuracy of the developed models has been compared based on values of mean absolute error (MAE), and root mean square error (RMSE). Secondly, the model with lowest values of MAE, and RMSE has been applied as objective function for optimization of process using imperialist competitive algorithm (ICA). After selection of optimal bending parameters, a confirmation test has been conducted to prove the optimal solutions. Results indicated that the radial basis network fulfills precise prediction of process rather than the other developed models. Also, confirmation tests proved that both RBFNN and ICA could predict and optimize the process vigorously.

Similar content being viewed by others

References

Kalpakjian S, Schmid SR (2001) Manufacturing engineering and technology, Ch. 16. Prentice-Hall, Upper Saddle River

Schuler GH (1998) Metal forming handbook, Ch. 4. Springer-Verlag, Berlin

Lange K (1985) Handbook of metal forming, Ch. 1. McGraw-Hill, New York

Thipprakmas S, Rojananan S (2008) Investigation of negative spring-go phenomenon using finite element method. Mater Des 29:1526–1532

Tekiner Z (2004) An experimental study of the examination of springback of sheet metals with several thicknesses and properties in bending dies. J Mater Process Technol 145:109–117

Moon YH, Kang SS, Cho JR, Kim TG (2003) Effect of tool temperature on the reduction of the springback of aluminium sheets. J Mater Process Technol 132:365–368

Li X, Yang Y, Wang Y, Bao J, Li S (2002) Effect of the material-hardening mode on the springback simulation accuracy of V-free bending. J Mater Process Technol 123:209–211

Cho JR, Moon SJ, Moon YH, Kang SS (2003) Finite element investigation on springback characteristics in sheet metal U-die bending process. J Mater Process Technol 141:109–116

Gomes C, Onipede O, Lovell M (2005) Investigation of springback in high strength anisotropic steels. J Mater Process Technol 159:91–98

Bozdemir M, Gulcu M (2008) Artificial neural network analysis of springback in V bending. J Appl Sci 8(17):3038–3043

Liu W, Liu Q, Ruan F, Liang Z, Qiu H (2007) Springback prediction for sheet metal forming based on GA–ANN technology. J Mater Process Technol 187:227–231

Ruffini R, Cao J (1998) Using neural network for springback minimization in a channel forming process. Dev Sheet Metal Stamping 1322:77–85

Pathak KK, Panthi S, Ramakrishnan N (2005) Application of neural network in sheet metal bending process. Def Sci J 55:125–131

Forcellese A, Gabriella F (2001) Artificial neural-network-based control system for springback compensation in press-brake forming. Int J Mater Prod Technol 16:545–563

Inamdar M, Narasimhan K, Maiti SK, Singh UP (2000) Development of an artificial neural network to predict spring-back in air vee bending. Int J Adv Manuf Technol 16:376–381

Viswanathan V, Kinsey B, Cao J (2003) Experimental implementation of neural network spring-back control for sheet metal forming. J Eng Mater Technol 125:141

Cao J, Kinsey B, Solla SA (2000) Consistent and minimal springback using a stepped binder force trajectory and neural network control. J Eng Mater Technol 122:113–118

Kazan R, Fırat M, Tiryaki AE (2009) Prediction of spring-back in wipe-bending process of sheet metal using neural network. Mater Des 30:418–423

Rahmani B, Alinejad G, Bakhshi-Jooybari M, Gorji A (2010) An investigation on spring-back/negative spring-back phenomena using finite element method and experimental approach. Proc IME B J Eng Manufact 223:841–850

Atashpaz-Gargari E, Lucas C (2007) Imperialist competitive algorithm: an algorithm for optimization inspired by imperialistic competition. IEEE Congr Evol Comput CEC 2007:4661–4667

Atashpaz-Gargari E, Hashemzadeh F, Rajabioun R, Lucas C (2008) Colonial competitive algorithm: a novel approach for PID controller design in MIMO distillation column process. Int J Intell Comput Cybernet 3(1):337–355

Kaveh A, Talatahari S (2010) Optimum design of skeletal structures using imperialist competitive algorithm. Comput Struct 88:1220–1229

Kaveh A, Talatahari S (2010) Imperialist competitive algorithm for engineering design problems. Asian J Civil Eng 11(6):675–697

Wilson F (1965) ASTME Die design handbook, 2nd edn. McGraw-Hill, New York

Marciniak Z, Duncan JL, Hu SJ (2002) Mechanics of sheet metal forming. Butterworth-Heinemann, Oxford

Hagan MT, Demuth HB, Beale M (1996) Neural network design. PWS Publishing Company, Boston

Nielsen RH (1987) Counter propagation networks. Appl Optics 26:4979–4985

Yang SH, Srinivas J, Mohan S, Lee DM, Blajee S (2009) Optimization of electric discharge machining using simulated annealing. J Mater Process Technol 2094471-4475

Joshi SN, Pande SS (2011) Intelligent process modelling and optimization of die-sinking electric discharge machining. Appl Soft Comput 11:2743–2755

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teimouri, R., Baseri, H., Rahmani, B. et al. Modeling and optimization of spring-back in bending process using multiple regression analysis and neural computation. Int J Mater Form 7, 167–178 (2014). https://doi.org/10.1007/s12289-012-1117-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1117-4