Abstract

It was already stated that springback in sheet metal forming strongly depends on the elastic properties. Several experimental investigations have revealed that the elastic modulus decreases as the plastic strain increases. Two approaches have been separately employed to explain this phenomenon: dislocations rearrangements and damage. These approaches are considered in a proposed elastoplastic model coupled with damage based on Lemaitre type isotropic ductile damage law. In addition, a hysteresis aspect, which is experimentally observed during unloading-reloading stages, is also considered. Uniaxial tension tests have been used and the predicted results agree well with published experimental data. The proposed model is intended to be implemented in FEM codes for reliable results in forming processes including springback.

Similar content being viewed by others

References

Yamaguchi K, Adachi H, Takakura N (1998) Effects of plastic strain path on Young’s modulus of sheet metals. Metals Mater 4:420–425

Yang M, Akiyama Y, Sasaki T (2004) Evaluation of change in material properties due to plastic deformation. J Mat Proc 151:232–236

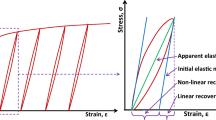

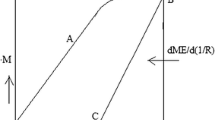

Cleveland RM, Ghosh AK (2002) Inelastic effects on springback in metals. Int J Plast 18:769–785

Benito JA, Manero JM, Jorba J, Roca A (2005) Change of Young’s modulus of cold-deformed pure iron in a tensile test. Metall Mater Trans A 36:3319

Yoshida F, Uemori T, Fujiwara K (2002) Elastic-plastic behavior of steel sheets under in-plane cyclic tension-compression at large strain. Int J Plast 18:633–659

Yoshida F, Uemori T (2003) A model of large-strain cyclic plasticity and its application to springback simulation. Int J Mech Sci 45:1687–1702

Yu HY (2009) Variation of elastic modulus during plastic deformation and its influence on springback. Mater Des 30:846–850

Eggertsen PA, Mattiasson K (2009) On the modelling of the bending–unbending behaviour for accurate springback predictions. Int J Mech Sci 51:547–563

Halilovič M, Vrh M, Štok B (2009) Prediction of elastic strain recovery of a formed steel sheet considering stiffness degradation. Meccanica 44:321–338

Vrh M, Halilovič M, Starman B, Štok B (2009) Modelling of springback in sheet metal forming. Int J Mater Form 2:825–828

Vrh M, Halilovič M, Štok B (2011) The evolution of effective elastic properties of a cold, formed stainless steel sheet. Exp Mech 51:677–695

Hambli R, Mkaddem A, Potiron A (2003) Damage prediction in L-bending processes using FEM. Int J Adv Manuf Technol 22:12–19

Yilamu K, Hino R, Hamasaki H, Yoshida F (2010) Air bending and springback of stainless steel clad aluminum sheet. J Mater Process Technol 272–278

Ghaei A, Green DE, Taherizadeh A (2010) Semi-implicit numerical integration of Yoshida–Uemori two-surface plasticity model. Int J Mech Sci 52:531–540

Ghaei A, Green DE (2010) Numerical implementation of Yoshida–Uemori two-surface plasticity model using a fully implicit integration scheme. Comput Mater Sci 48:195–205

Eggertsen PA, Mattiasson K (2010) On constitutive modeling for springback analysis. Int J Mech Sci 52:804–818

Kubli W, Krasovskyy A, Sester M (2008) Modeling of reverse loading effects including workhardening stagnation and early replastification. Int J Mater Form (Suppl 1):145–148, doi 10.1007/s12289-008-0012-5

Eggertsen PA, Mattiasson K (2010) On the modeling of the unloading modulus for metal sheets. Int J Mater Form 3:127–130

Bonora N, Gentile D, Pirondi A, Newaz G (2005) Ductile damage evolution under triaxial state of stress: theory and experiments. Int J Plast 21:981–1007

Lemaître J, Chaboche J-L (1985) Mécanique des matériaux solides, Dunod Eds, Paris

Badreddine H, Saanouni K, Dogui A (2010) On non-associative anisotropic finite plasticity fully coupled with isotropic ductile damage for metal forming. Int J Plast 26:1541–1575

Celentano DJ, Chaboche J-L (2007) Experimental and numerical characterization of damage evolution in steels. Int J Plast 23:1739–1762

Chatti S, Hermi N (2011) The effect of non-linear recovery on springback prediction. Comput Struct 89:1367–1377

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chatti, S. Modeling of the elastic modulus evolution in unloading-reloading stages. Int J Mater Form 6, 93–101 (2013). https://doi.org/10.1007/s12289-011-1075-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-011-1075-2