Abstract

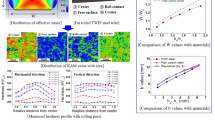

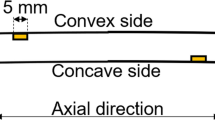

Numerical simulation is used to study patented high-C steel flat-rolled wire cold forming processes. An elasto-plastic power law, identified from mechanical tests, is used into Forge2005® finite element (FEM) package in order to describe the material behaviour during wire drawing followed by cold rolling. A through-process approach has been favoured, transferring residual wire-drawing stresses and strain into the flat-rolling preform. This mechanical analysis, associated with a triaxiality study, points to dangerous areas where fracture may initiate due to high tensile stresses. Lemaître’s isotropic damage criterion, including crack closure effect, a -1/3 cut-off value of stress triaxiality, and tension/compression damage asymmetry, has been used and has confirmed the previous analysis. A number of non-coalesced voids nucleated on inclusions have been observed in the Scanning Electron Microscopy (SEM), especially in high-deformation zones (“blacksmith’s cross”). Their evolution has been simulated in the FEM model using spherical numerical markers, which deform into oblate or prolate ellipsoids. The deformation-induced morphological evolution of voids observed in the SEM compares well with the geometrical evolution of the markers, which suggests that the morphologies observed do not result from micro-crack propagation, but from material transport of the nucleated voids.

Similar content being viewed by others

Abbreviations

- x :

-

Scalar

- x ij :

-

Component of a second order tensor x

- \( \mathop{x}\limits^{ \bullet } \) :

-

Material time derivative of x \( \left( {\mathop{x}\limits^{ \bullet } = dx/dt} \right) \)

- x kk :

-

Trace of x

- δ ij :

-

Kronecker delta, \( {\delta_{{ij}}} = 1\,if\,i = j\,and\,{\delta_{{ij}}} = 0\,if\,i \ne j \)

- \( \left\langle x \right\rangle \) :

-

Macauley bracket, \( \left\langle x \right\rangle = x\,if\,x \geqslant 0\,and\,\left\langle x \right\rangle = 0\,if\,x < 0 \)

- \( {\left\langle x \right\rangle^{ + }}or\left\langle x \right\rangle_{{ij}}^{ + } \) :

-

Positive part in terms of principal component of tensor x

- \( {\left\langle x \right\rangle^{ - }}or\left\langle x \right\rangle_{{ij}}^{ - } \) :

-

Negative part in terms of principal component of tensor x

- a :

-

Behaviour law parameter

- E :

-

Young’s modulus of elasticity

- h :

-

Microdefect closure parameter

- K :

-

Behaviour law parameter

- \( \overline m \) :

-

Friction factor

- n :

-

Strain hardening index in the behaviour law

- R :

-

Current wire radius

- R 0 :

-

Initial wire radius

- R a :

-

Centre Line Average (CLA) roughness

- R ν :

-

Triaxiality function

- s :

-

Unified damage law exponent

- S :

-

Energetic damage law parameter

- Tr :

-

Stress triaxiality

- Y :

-

Energy density release rate

- ε eq :

-

Equivalent strain

- \( {\mathop{\varepsilon }\limits^{ \bullet }_{{eq}}} \) :

-

Equivalent strain rate

- \( {\mathop \varepsilon \limits^ \bullet }^{p}_{{ij}} \) :

-

Plastic strain rate

- \( {\mathop \varepsilon \limits^ \bullet }^{p}_{{eq}} \) :

-

Equivalent plastic strain rate

- ν :

-

Poisson’s ratio of elastic contraction

- ρ:

-

Mass density

- σ, σ ij :

-

Uniaxial and tensorial Cauchy stresses

- \( {\tilde{\sigma }_{{ij}}} \) :

-

Effective stress

- σ y :

-

Tensile yield stress

- σ eq :

-

Equivalent stress

- \( {\tilde{\sigma }_{{eq}}} \) :

-

Effective equivalent stress

- σ H :

-

Hydrostatic stress

- τ c :

-

Shear stress

- Ψ*:

-

Gibbs specific free enthalpy

- \( \psi_e^{*} \) :

-

Elastic specific free enthalpy

- Ψ p :

-

Plastic state potential (Helmholtz free energy)

- Ψ T :

-

Thermal state potential

References

Pokorny A, Pokorny J (1985) Inclusions non métalliques dans l’acier. Techniques de l’Ingénieur, M220, in French

Avitzur B (1963) Analysis of wire drawing and extrusion through conical dies of small cone angle. J Eng Ind 89:89–96

Avitzur B (1968) Analysis of central bursting defects in extrusion and wire drawing. Trans ASME, J Eng Ind 90:79

Zimerman Z, Avitzur B (1970) Analysis of the effect of strain hardening on central bursting defects in drawing and extrusion. Trans ASME, J Eng Ind 92:135

Zimerman Z, Darlington H, Kottkamp EH (1971) Selection of operating parameters to prevent central bursting defects during cold extrusion. In: Hoffmanner AL (ed) Metal forming: interrelation between theory and practice. Plenum, New York, p 47

Chen CC, Si Oh, Kobayashi S (1979) Ductile fracture in axisymmetric extrusion and drawing. Trans ASME, J Eng Ind 101(2):36–44

Chevalier L (1992) Prediction of defects in metal forming: application to wire drawing. J Mater Process Technol 32:145–153

Choi S, Lee YS, Oh HK (1998) Ductile fracture in axisymmetric extrusion. J Mater Process Technol 74:263–267

Ko DC, Kim BM (2000) The prediction of central burst defects in extrusion and wire drawing. J Mater Process Technol 102:19–24

Mariage JF, Saanouni K, Lestriez P (2002) Numerical simulation of extrusion with central bursting prediction by continuum damage mechanics. In: Proceeding of the 5th international ESAFORM Conference on Material Forming, Krakow, 475–478

Saanouni K, Mariage JF, Cherouat A, Lestriez P (2004) Numerical prediction of discontinuous central bursting in axisymmetric forward extrusion by continuum damage mechanics. Comput Struct 82:2309–2332

Gouveia BPPA, Rodrigues JMC, Martins PAF (1996) Fracture predicting in bulk metal forming. Int J Mech Sci 38(4):361–372

McAllen P, Phelan P (2007) Numerical analysis of axisymmetric wire drawing by means of a coupled damage model. J Mater Process Technol 183:210–218

McAllen P, Phelan P (2005) A method for the prediction of ductile fracture by central bursts in axisymmetric extrusion. J Mech Eng Sci 219(C3):237–250

Kuboki T, Abe M, Neishi Y, Akiyama M (2005) Design method of die geometry and pass schedule by void index in multi-pass drawing. J Manuf Sci Eng 127:173–182. doi:10.1115/1.1830490

Campos HB, Cetlin PR (1998) The influence of die semi-angle and of the coefficient of friction on the uniform tensile elongation of drawn copper bars. J Mater Process Technol 80–81:388–391

Vallellano C, Cabanillas PA, Garcıa-Lomas FJ (2008) Analysis of deformations and stresses in flat rolling of wire. J Mater Process Technol 195:63–71

Kazeminezhad M, Karimi Taheri A (2005) An experimental investigation on the deformation behavior during wire flat rolling process. J Mater Process Technol 160:313–320

Kazeminezhad M, Karimi Taheri A (2005) A theoretical and experimental investigation on wire flat rolling process using deformation pattern. Mater Des 26:99–103

Utsunomiya H, Hartley P, Pillinger I (2001) Three-dimensional elastic-plastic finite-element analysis of the flattening of wire between plain rolls. J Manuf Sci Eng 123:397–404

Kazeminezhad M, Karimi Taheri A, Kiet Tieu A (2008) A study on the cross-sectional profile of flat rolled wire. J Mater Process Technol 200:325–330

Massé T (2010) Study and optimization of high carbon steel flat wires. PhD report, CEMEF, MinesParistech, Sophia-Antipolis, France

Bobadilla C, Persem N, Foissey S (2007) Modelling of the drawing and rolling of high carbon flat wires. In AIP Conference 907:535–540

Cherouat A, Saanouni K, Hammi Y (2003) Improvement of forging process of a 3D complex part woth respect to damage occurrence. J Mater Process Technol 142:307–317

Teixeira P, Santos AD, Andrade Pires FM, César de Sá JMA (2006) Finite element prediction of ductile fracture in sheet metal forming processes. J Mater Process Technol 177:278–281

Lemaître J (1984) How to use damage mechanics. Nucl Eng Des 80:233–245

Lemaitre J, Desmorat R (2005) Engineering damage mechanics: ductile, creep, fatigue and brittle failures. Springer, Berlin

Kachanov LM (1958) On the time to rupture under creep conditions. Izv Acad Nauk SSSR, OTN 8:26–31

Lemaître J (1971) Evaluation of dissipation and damage in metals submitted to dynamic loading Proc. Int. conf. Materials, n°1, Kyoto, p 540

Lemaître J, Chaboche JL (1978) Aspects Phénoménologiques de la Rupture Par Endommagement. J Mech Appl 2:317

Ladevèze P, Lemaitre J (1984) Damage effective stress in quasi-unilateral material conditions. In: Proc. of the 16th International Congress of Theoretical and Applied Mechanics. Lyngby, Denmark

Bao Y, Wierzbicki T (2005) On the cut-off value of negative triaxiality for fracture. Eng Fract Mech 72:1049–1069

Balan T (2005) Parameter identification of steel behaviour laws through the simulation of wire drawing. Proc. of the International Conference on Drawing, Zakopane. Poland

Fereshteh-Saniee F, Pillinger I, Hartley P (2004) Friction modelling fort the physical simulation of the bulk metal forming processes. J Mater Process Technol 153–154:151–156

Kubié J (1980) Le test de bipoinçonnement: étude théorique—application à l’étude du transfert de matière dans un contact frottant. PhD Thesis, Mines Paristech, in French

De Vathaire M, Kubié J (1982) An evaluation of the plain strain compression test. Experimental study of the friction test. II. Role of transfer layers in boundary lubrication. J Lubr Technol 104:545–551

Forestier R (2003) Développement d’une méthode d’identification de paramètres par analyse inverse couplée avec un modèle éléments finis. PhD report, CEMEF, MinesParistech, Sophia-Antipolis, France, in French

Fayolle S (2008) Etude de la modélisation de la pose et de la tenue mécanique des assemblages par deformation plastique. Application au rivetage auto-poinçonneur. PhD report, CEMEF, MinesParistech, Sophia-Antipolis, France, in French

Lemaître J (1985) A continuous damage mechanics model for ductile fracture. ASME J Eng Mater Technol 107:83–89

Ben Tahar M (2005) Contribution à l’étude et la simulation du procédé d’hydroformage. PhD report, CEMEF, MinesParistech, Sophia-Antipolis, France, in French

Boussetta R (2005) Estimateurs d’erreur et remaillage adaptatif: application à la simulation 3D des procédés de mise en forme des matériaux. PhD report, CEMEF, MinesParistech, Sophia-Antipolis, France, in French

Kazeminezhad M, Karimi Taheri A (2006) Prediction of macroscopic shear bands in flat rolled wire using the finite and slab element method. Mater Lett 60:3265–3268

Kazeminezhad M, Karimi Taheri A (2008) The effect of 3D and 2D deformations on flattened wires. J Mater Process Technol 202:553–558

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46:81–98

Massé T, Chastel Y, Montmitonnet P, Bobadilla C, Persem N, Foissey S (2011) Impact of mechanical anisotropy on the geometry of flat-rolled fully pearlitic steel wires. J Mater Process Technol 211:103–112

Ladevèze P (1983) On an anisotropic damage theory. In: Boehler JP (ed) Proc. CNRS Int. Coll. 351 Villars-de-Lans, Failure criteria of structured media, 1993, pp 355–363

Gologanu M, Leblond JB, Devaux J (2001) Approximate models for ductile metals containing nonspherical voids—case of axisymmetric prolate ellipsoidal cavities. J Mech Phys Solids 41:1723–1754

Gologanu M, Leblond JB, Devaux J (1994) Approximate models for ductile metals containing nonspherical voids—case of axisymmetric oblate ellipsoidal cavities. J Eng Mater Technol 116:290–297

Gologanu M, Leblond JB, Perrin G, Devaux J (1995) Recent extensions of Gurson’s model for porous ductile metals. In: Suquet P (ed) Continuum micromechanics. Springer-Verlag, Berlin

Gologanu M, Leblond JB, Perrin G, Devaux J (2001) Theoretical models for void coalescence in porous ductile solids I. Coalescence “in layers”. Int J Solids Struct 38:5581–5594

Croix P, Lauro F, Oudin J, Christlein J (2003) Improvement of damage prediction by anisotropy of microvoids. J Mater Process Technol 134–144:202–208

Siruguet K, Leblond JB (2004) Effect of void locking by inclusions upon the plastic behavior of porous ductile solids—part I: theoretical modelling and numerical study of void growth. Int J Plast 20:225–268

Comi C, Perego U (2001) Fracture energy based bi-dissipative damage model for concrete. Int J Solids Struct 38:6427–6454

Acknowledgments

The Research Centre of ArcelorMittal Gandrange and ArcelorMittal Wire Solutions are both gratefully acknowledged, for financial support as well as for generous access to their production and research facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Massé, T., Chastel, Y., Montmitonnet, P. et al. Mechanical and damage analysis along a flat-rolled wire cold forming schedule. Int J Mater Form 5, 129–146 (2012). https://doi.org/10.1007/s12289-011-1032-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-011-1032-0