Abstract

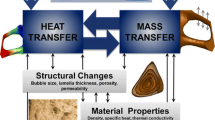

The change of rheological and morphological properties of bread dough during the baking step is numerically studied on the base of the model derived for the proofing step in a previous paper. Starting from the numerical foam structure obtained after proofing, the baking step is calculated, taking into account the thermomechanical couplings and the impact of dough thermosetting. The results show the potentiality of the model to describe baking as a dough solidification by increase of temperature, what is accounted for by a kinetic law. Bubble size distribution in the dough volume can be estimated as function of applied thermal conditions. The order of magnitude of the calculated parameters is in qualitative agreement with experimental data from the literature, such as global volume increase (20%) and decreasing bubble radius from core to outer layers, i.e. from crumb to crust.

Similar content being viewed by others

References

Mondal A, Datta AK (2008) Bread baking —a review. J Food Eng 86:465–474

de Vries U, Sluimer P, Bloksma A (1989) A quantitative model for heat transport in batter and crumb during baking. In: NG Asp. (Ed.), Cereal Science and Technology in Sweden, Ystad, Sweden: Lund University, pp. 74 –88

Zanoni B, Pierucci S, Peri C (1994) Study of the bread baking process. II. Mathematical modeling. J Food Eng 23:321–336

Thorvaldsson K, Skjöldebrand C (1998) Water diffusion in bread during baking. Lebens Wiss Technol 31:658–663

Sommier A, Chiron H, Colonna P, Della Valle G, Rouillé J (2005) An instrumented pilot scale oven for the study of French bread baking. J Food Eng 69:97–106

de Cindio B, Correra S (1995) Mathematical modeling of leavened cereal goods. J Food Eng 24:379–403

Thorvaldsson K, Janestad H (1999) A model for simultaneous heat, water, and vapor diffusion. J Food Eng 40:167–172

Lostie M, Peczalski R, Andrieu J, Laurent M (2002) Study of sponge cake batter baking process. Part 1: Experimental data. J Food Eng 51:131–137

Lostie M, Peczalski R, Andrieu J, Laurent M (2002) Study of sponge cake batter baking process. Part 2: Modelling and parameter estimation. J Food Eng 55:349–357

Wagner M, Zhang L, Quellec S, Doursat C, Flick D, Trystram G, Lucas T (2006) Role of the crust formation on local expansion during bread baking. In: Campbell G, Pyle L, Scanlon M (eds) Proceedings of “Bubbles in Food: Novelty, Health and Luxury”. UK, Windermere

Fan J, Mitchell JR, Blanshard JMV (1999) A model for the oven rise of dough during baking. J Food Eng 41:69–77

Zhang J, Datta AK (2006) Mathematical modeling of bread baking process. J Food Eng 75:78–89

Purlis E, Salvadori VO (2009) Bread baking as a moving boundary problem. Part 2: model validation and numerical simulation. J Food Eng 91:434–442

Bikard J, Coupez T, Della Valle G, Vergnes B (2008) Simulation of bread making process using a direct 3D numerical method at microscale: analysis of foaming phase during proofing. J Food Eng 35:259–267

Wang FC, Sun XS (1999) Thermal expansion of flour-water dough measured with a dynamic mechanical analyzer. Cereal Chem 76:87–91

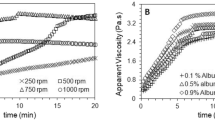

Singh AP, Battacharya M (2005) Development of dynamic modulus and cell opening of dough during baking. J Text Stud 36:44–67

Stathopoulos CE, Tsiami AA, Schofield JD, Dobraszczyk BJ (2008) Effect of heat on rheology, surface hydrophobicity and molecular weight distribution of glutens extracted from flours with different bread-making quality. J Cereal Sci 47:134–143

Bloksma AH (1980) Effect of heating rate on viscosity of wheat flour doughs. J Text Stud 10:261–269

Rolee A, LeMeste M (1999) Effect of moisture content on thermomechanical behavior of concentrated wheat starch-water preparations. Cereal Chem 76:452–458

Gan Z, Ellis PR, Schofield JD (1995) Gas cell stabilisation and gas retention in wheat bread dough. J Cereal Sci 21:215–230

Perzina P (1966) Fundamentals problems in visco-plasticity. In Press A (Ed.) Recent Advances in Applied Mechanics, pp. 147 –172

Aranguren MI, Williams RJJ (1986) Kinetic and statistical aspects of the formation of polyurethanes from toluene diisocyanate. Polymer 27:425–430

Dimier F, Sbirrazzuoli N, Vergnes B, Vincent M (2004) Curing kinetics and chemorheological analysis of polyurethane formation. Polym Eng Sci 44:518–527

Piloyan GO, Ryabchikov ID, Novikora OS (1966) Determination of activation energies of chemical reactions by differential thermal analysis. Nature 5067:1229–1229

Vergnes B, Della Valle G, Colonna P (2003) Rheological properties of biopolymers and applications to cereal processing. In: Kaletunç G, Breslauer KJ (eds) Characterization of Cereal and Flours, Properties, Analysis and Applications. Marcel Dekker, New York, pp 209–265

Dobraszczyk BJ (2004) The physics of baking: rheological and polymer molecular structure-function relationships in breadmaking. J Non-Newt Fluid Mech 124:61–69

Dobraszczyk BJ, Morgenstern MP (2003) Rheology and the breadmaking process. J Cereal Sci 38:229–245

Rouillé J, Della Valle G, Lefebvre J, Sliwinski E, VanVliet T (2005) Shear and extensional properties of bread doughs affected by their minor components. J Cereal Sci 42:45–57

Castro JM, Macosko CW (1980) Kinetics and rheology of typical polyurethane reaction injection molding systems. SPE ANTEC Technical Papers, 434 –438

Pichelin E, Coupez T (1999) Finite element solution of the 3D mold filling problem for viscous incompressible fluid. Comput Meth Appl Mech Eng 163:359–371

Bruchon J, Coupez T (2003) Étude 3D de la formation d’une structure de mousse polymère par simulation de l’expansion anisotherme de bulles de gaz. Mécanique & Industrie 4:331–338

Bikard J, Bruchon J, Coupez T, Vergnes B (2005) Numerical prediction of the foam structure of polymeric materials by direct 3D simulation of their expansion by chemical reaction based on a multidomain method. J Mat Sci 40:5875–5881

Rask C (1989) Thermal properties of dough and bakery products: a review of published data. J Food Eng 9:167–193

Drouzas AE, Saravacos GO (1988) Effective thermal conductivity of granular starch materials. J Food Sci 53:1795–1799

Drouzas AE, Maroulis ZB, Karathanos VT, Saravacos GO (1991) Direct and indirect determination of the effective thermal diffusivity of granular starch. J Food Eng 13:91–101

Maroulis ZB, Shah KK, Saravacos GO (1991) Thermal conductivity of gelatinized starches. J Food Sci 51:113–115

Bloksma AH (1986) Rheological aspects of structural changes during baking. In: Blanshard JMV, Frazier PJ, Galliard T (eds) Chemistry and Physics of Baking. The Royal Society of Chemistry, London, pp 170–178

Bloksma AH (1990) Rheology of the breadmaking process. Cereal Foods World 35:228–236

Amon M, Denson DC (1984) A study of the dynamics of foam growth: analysis of the growth of closely spaced spherical bubbles. Polym Eng Sci 24:1026–1034

Amon M, Denson DC (1986) A study of the dynamics of foam growth: simplified analysis and experimental results for bulk density in structural foam molding. Polym Eng Sci 26:255–267

Arefmanesh A, Advani SG (1991) Diffusion-induced growth of a gas bubble in a viscoelastic fluid. Rheol Acta 30:274–283

Shafi MA, Joshi K, Flumerfelt RW (1997) Bubble size distribution in freely expanded polymer foams. Chem Eng Sci 52:635–644

Weegels PL, Verhoek JA, de Groot AMG, Hamer RJ (1994) Effects on gluten of heating at different moisture contents. I. Changes in functional properties. J Cereal Sci 19:31–38

Babin P, Della Valle G, Chiron H, Cloetens P, Hoszowska J, Pernot P, Réguerre AL, Salvo L, Dendievel R (2008) In situ fast X-Ray tomography study of the evolution of cellular structure in bread dough during proofing and baking. In: Campbell GM, Pyle DL, Scanlon MG (Eds.) Bubbles in Food II, pp 265–272

Zanoni B, Peri C, Pierucci S (1993) A study of the bread baking process. I. A phenomenological model. J Food Eng 19:389–398

Wagner M (2005) Suivi local et dynamique par IRM lors de la cuisson du pain et étude des mécanismes contrôlant la mise en place de la structure alvéolaire, Doctoral Thesis, ENSIA, Massy

Rouillé J (2003) Mécanismes d’alvéolation de la pâte et la mie de pain français, Doctoral Thesis, Ecole Polytechnique de l’Université de Nantes

Acknowledgements

J. Bikard was granted by the French Ministère de la Recherche, through the project CANAL - SALVE, within which all partners are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bikard, J., Coupez, T., Della Valle, G. et al. Simulation of bread making process using a direct 3D numerical method at microscale: analysis of baking step. Int J Mater Form 5, 11–24 (2012). https://doi.org/10.1007/s12289-010-1018-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-010-1018-3