Abstract

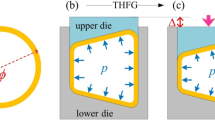

Tubular components, such as stepped tubes, conical tubes and box shape tubes, are mainly produced in tube hydroforming process. Obtaining a sharp corner is a main goal in some of these components. In this paper, the corner filling in stepped tubes is studied by a multistage new die. The proposed die was simulated and the filling of die cavity was investigated. In this respect, the finite element software, ABAQUS 6.4, has been used for simulation. In order to verify the simulation results, the new die of stepped tube was manufactured and some experiments have been performed. The results obtained from the experiments verified the simulation results. It is shown that by using the new die parts with sharp corners could be produced. The simplicity of the die and low internal pressure are another advantages of this die. The thickness distribution was also examined by both the FE simulation and experiments and it is shown that a better distribution could be obtained by the proposed die set.

Similar content being viewed by others

References

Koc M, Allen T, Jiratheranat S, Altan T (2000) The use of FEA and design of experiments to establish design guideline for simple hydroforming parts. Int J of Mach Tools Manufact 40:2249–2266

Kim J, Kang B-S (2002) Implementation of backward tracing scheme of the FEM for design of initial tubular blank in hydroforming. J Mater Process Technol 125–126:839–848

Koc M, Altan T (2002) Application of two dimensional (2D) FEA for the tube hydroforming process. Int J of Mach Tools Manufact 42:1285–1295

Koc M, Altan T (2002) Predication of forming limits and parameters in the tube hydroforming process. Int J of Mach Tools Manufact 42:123–138

Kridli GT, Bao L, Mallick PK, Tian Y (2003) Investigation of thickness variation and corner filling in tube hydroforming. J Mater Process Technol 133:287–296

Fann K-J, Hsiao P-Y (2003) Optimization of loading conditions for tube hydroforming. J Mater Process Technol 140:520–524

Hwang Y-M, Chen W-C (2005) Analysis of tube hydroforming in a square cross-section die. Int J of Plasticity 21:1815–1833

Gang L, Shijian Y, Bugang T (2006) Analysis of thinning at the transition corner in tube hydroforming. J Mater Process Technol 177:688–691

Loh-Mousavi M, Mori K, Hayashi K, Bakhshi-Jooybari M (2007) Improvement of filling die corners in box-shaped tube hydroforming by control of wrinkling. Key Engineering Materials 334:461–467

Loh-Mousavi M, Mori K, Hayashi K, Maki S, Bakhshi M (2007) 3D finite element simulation of pulsating T-shape hydroforming of tubes. Key Eng Mater 340–341:353–358

Elyasi M, Bakhshi-Jooybari M, Gorji AH, Nourouzi S, Alinejad GM (2008) Numerical and experimental investigation on forming metallic bellows in closed and open die hydroforming. Steel Res Int 79:148–154

ABAQUS CAE 6.4 (2003) Theory Manual. Hibbit, Karlsson, Sorensen, Inc

Ngaile G, Jaeger S, Altan T (2004) Lubrication in tube hydroforming (THF) Part I. Lubrication mechanisms and development of model tests to evaluate lubricants and die coatings in the transition and expansion zones. J Mater Process Technol 146:108–115

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elyasi, M., Bakhshi-Jooybari, M. & Gorji, A. A new die design for the hydroforming of stepped tubes. Int J Mater Form 3, 71–75 (2010). https://doi.org/10.1007/s12289-009-0419-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-009-0419-7