Abstract

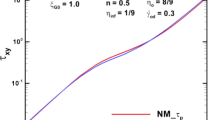

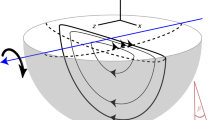

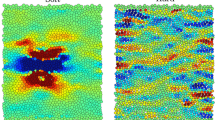

Many material forming processes involve liquid–liquid mixing, and in general the induced properties are strongly dependent on the resulting microstructure. Microstructure during liquid–liquid mixing exhibits a morphology characterized by a length scale usually much smaller that the one associated with the macroscopic flow. In this context a microstructure description allowing to characterize the microscopic morphology, its characteristic size, shape and orientation as well as the time evolution of the specific interface area, seems to be necessary in order to qualify and even quantify, the ability of flows to perform mixing, leading to the definition of optimal flows to maximize some desired criteria. The approach based on the definition of area tensor is a promising description of such phenomena, being its main drawback the necessity of introducing a closure relation to derive the equation governing its time evolution, whose impact on the computed solution can be in some cases significant. In this paper we propose a new description which considers the area tensor description as starting point, but defines its evolution in a kinetic theory framework, avoiding the introduction of any closure relation.

Similar content being viewed by others

References

Ammar A, Ryckelynck D, Chinesta F, Keunings R (2006) On the reduction of kinetic theory models related to finitely extensible dumbbells. J Non-Newton Fluid Mech 134:136–147

Ammar A, Mokdad B, Chinesta F, Keunings R (2006) A new family of solvers for some classes of multidimensional partial differential equations encountered in kinetic theory modeling of complex fluids. J Non-Newton Fluid Mech 139:153–176

Chella R, Ottino JM (1985) Stretching in some classes of fuid motions and asymptotic mixing efficiencies as a measure of flow classification. Arch Ration Mech Anal 90:15–42

Chinesta F, Chaidron G, Poitou A (2003) On the solution of Fokker–Planck equations in steady recirculating flows involving short fiber suspensions. J Non-Newton Fluid Mech 113:97–125

Doi M, Ohta T (1991) Dynamics and rheology of complex interfaces. J Chem Phys 95:1242–1248

Hall KR, Godfrey JC (1968) The mixing rates of highly viscous Newtonian and non-Newtonian fluids in a laboratory sigma-blade mixer. Trans Inst Chem Eng 46:205–212

Keunings R (2004) Micro-macro methods for the multiscale simulation viscoelastic flow using molecular models of kinetic theory. In: Binding DM, Walters K (eds) Rheology reviews. British Society of Rheology, UK, pp 67–98

Lee HM, Park OO (1994) Rheology and dynamics of immiscible polymer blends. J Rheol 38:1405–1425

Mackley MR, Neves Saraiva RMC (1999) The quantitative description of fluid mixing using Lagrangian- and concentration-based numerical approaches. Chem Eng Sci 54:159–170

Öttinger HC, Laso M (1992) Smart polymers in finite element calculation. Int Congress on Rheology, Brussels, Belgium

Ottino JM (1989) The kinematics of mixing: stretching, chaos and transport. Cambridge University Press, UK

Pironneau O (1989) Finite methods for fluids Wiley, New York

Rielly CD, Smith DLO, Lindley JA, Niranjan K, Philips VR (1994) Mixing processes for agricultural and food materials: Part 4, assessment and monitoring of mixing systems. J Agric Eng Res 29:1–18

Roberts EPR, Mackley MR (1995) The simulation of stretch rates for the quantitative prediction and mapping of mixing within a channel flow. Chem Eng Sci 50:3727–3746

Wetzel ED, Tucker CL III (1999) Area tensors for modeling microstructure during laminar liquid–liquid mixing. Int J Multiph Flow 25:35–61

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chinesta, F., Mackley, M.R. Microstructure evolution during liquid–liquid laminar mixing: a kinetic theory approach. Int J Mater Form 1, 47–55 (2008). https://doi.org/10.1007/s12289-008-0007-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-008-0007-2