Abstract

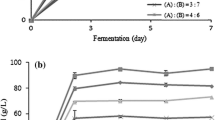

The waste product from salted Undaria pinnatifida (sea mustard) processing was fermented to produce bioethanol by Saccharomyces cerevisiae KCCM 1129 at laboratory and pilot development unit (PDU) scales. Thermal acidic hydrolysis of salted U. pinnatifida was conducted with 75 mM H2SO4 at 121℃ for 60 min and the addition of 1.4 KNU/mL Termamyl 120L. A total monosaccharide concentration of 19.3 g/L and 32.2% conversion from 59.9 g/L total carbohydrate using 130 g dw/L salted U. pinnatifida were achieved. Ethanol fermentations in 5 and 500 L fermenters were carried out to produce 8.5 g/L of ethanol with an ethanol yield (YEtOH) of 0.44 at 24 h and 7.9 g/L with YEtOH of 0.41 at 18 h, respectively. The fermentation time of the PDU-scale reaction was reduced due to differences in the impeller type and geometry of the fermenters.

Similar content being viewed by others

References

Singh, A., P. S. Nigam, and J. D. Murphy (2011) Renewable fuels from algae: An answer to debatable land based fuels. Bioresour. Technol. 102: 10–16.

Jang, J. S., Y. K. Cho, G. T. Jeong, and S. K. Kim (2012) Optimization of saccharification and ethanol production by simultaneous saccharification and fermentation (SSF) from seaweed, Saccharina japonica. Bioproc. Biosyst. Eng. 35: 11–18.

Usov, A., G. Smirnova, and N. Klochkova (2001) Polysaccharides of algae: 55. Polysaccharide composition of several brown algae from Kamchatka. Russ. J. Bioorg. Chem. 27: 395–399.

Wargacki, A. J., E. Leonard, M. N. Win, D. D. Regitsky, C. N. S. Santos, P. B. Kim, S. R. Cooper, R. M. Raisner, A. Herman, and A. B. Sivitz (2012) An engineered microbial platform for direct biofuel production form brown marcoalgae. Sci. 335: 308–313.

Bilan, M. I., A. A. Grachev, N. E. Ustuzhanina, A. S. Shashkov, N. E. Nifantiev, and A. I. Usov (2002) Structure of a fucoidan from the brown seaweed Fucus evanescens C. Ag. Carbohydr. Res. 337: 719–730.

Chizhov, A. O., A. Dell, H. R. Morris, S. M. Haslam, R. A. McDowell, and A. S. Shashkov (1991) A study of fucoidan from the brown seaweed Chorda filum. Carbohydr. Res. 320: 108–119.

Bilan, M. I., M. I. Kusaykin, A. A. Grachev, E. A. Tsvetkova, T. N. Zvyagintseva, N. E. Nifantiev, and A. I. Usov (2005) Effect of enzyme prepraration from the marine mollusk Littorina kurila on fucoidan from the brown alga Fucus distichus. Biochem. 70: 1321–1326.

Agbor, V. B., N. Cicek, R. Sparling, A. Berlin, and D. B. Levin (2011) Biomass pretreatment: Fundamentals toward application. Biotechnol. Advan. 29: 675–685.

Choi, D. B., H. S. Sim, Y. L. Piao, W. Ying, and H. Cho (2009) Sugar production from raw seaweed using the enzyme method. J. Ind. Eng. Chem. 15: 12–15.

Kim, H. J., C. H. Ra, and S. K. Kim (2013) Ethanol production from seaweed (Undaria pinnatifida) using yeast acclimated to specific sugars. Biotechnol. Bioproc. Eng. 18: 533–537.

Cho, Y. K., H. J. Kim, and S. K. Kim (2013) Bioethanol production from brown seaweed, Undaria pinnatifida, using NaCl acclimated yeast. Bioproc. Biosyst. Eng. 36: 713–719.

Cho, H. Y., C. H. Ra, and S. K. Kim (2013) Ethanol production from the seaweed, Gelidium amansii using specific sugar acclimated yeasts. J. Microbiol. Biotechnol. 24: 264–269.

Sanchez-Machado, D. I., J. Lopez-Cervantes, P. Paseiro-Losada, and J. Lopez-Hernandez (2004) Fatty acids, total lipid, protein and ash contents of processed edible seaweeds. Food Chem. 85: 439–444.

Rocha, G. J. M., C. Martin, V. F. N. da Silva, E. O. Gomez, and A. R. Goncalves (2012) Mass balance of pilot-scale pretreatment of sugarcane bagasse by steam explosion followed by alkaline delignification. Bioresour. Technol. 111: 447–452.

Horn, S. J., I. M. Aasen, and K. Østgaard (2000) Production of ethanol from mannitol by Zymobacter palmae. J. Ind. Microbiol. Biotechnol. 24: 51–57.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ra, C.H., Kang, CH., Jeong, GT. et al. Bioethanol production from the waste product of salted Undaria pinnatifida using laboratory and pilot development unit (PDU) scale fermenters. Biotechnol Bioproc E 19, 984–988 (2014). https://doi.org/10.1007/s12257-014-0179-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-014-0179-1