Abstract

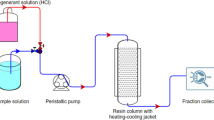

Biochemical 2,3-butanediol is a renewable material with the potential to be used as an alternative fuel. However, in the lack of an effective separation process has limited its industrial application. In this paper, an effective process was achieved to separate 2,3-butanediol by reactive-extraction. Acetaldehyde and cyclohexane were chosen as the reactant and extractant, respectively. Ion-exchange resin HZ732 was used as the catalyst. Reaction equilibrium and a kinetic study on the reaction between 2,3-butanediol and acetaldehyde were investigated to provide basic data for process development. The reaction enthalpy and activation energy of reaction of 2,3-butanediol and acetaldehyde were −30.05 ± 1.62 KJ/mol and 45.29 ± 2.89 KJ/mol, respectively. Feasible conditions were obtained as follows: operating temperature = 20°C, acetaldehyde: 2,3-butanediol = 0.5:1 (w/w), cyclohexane: fermentation broth = 0.5:1 (w/w), catalyst amount = 100 g/L, stirring rate = 500 rpm and three-stage counter-current extraction method was used. Under these conditions, the total yield rate of 2,3-butanediol from fermentation broth was over 90% and the mass fraction of 2,3-butanediol in the final product reached 99%.

Similar content being viewed by others

References

John, W. and N. Knowlton (1946) Physical chemical properties of the 2,3-butanediols. J. Amer. Chem. Soc. 68: 208–210.

Jansen, N. B., M. C. Flickinger, and G. T. Tsao (1984) Production of 2,3-butanediol from D-xylose by Klebsiella oxytoca ATCC8724. Biotechnol. Bioeng. 26: 362–369.

Yu, E. K. C. and N. Levitin (1982) Production of 2,3-butanediol by Klebsiella pneumoniae grown on aicd hydrolysed wood hemicellulose. Biotechnol. Lett. 4: 741–746.

Flickinger, M. C. (1980) Current biological research in conversion of cellulosic carbohydrates into liquid fuels: How far have we come. Biotechnol. Bioeng. 22: 27–48.

Biebl, H., A. P. Zeng, K. Menzel, and W. D. Deckwer (1998) Fermentation of glycerol to 1,3-propanediol and 2,3-butanediol by Klebsiella pneumoniae. Appl. Microbio. Biotechnol. 50: 24–29.

Garg, S. L. and A. Jain (1995) Fermentative production of 2,3-butanediol: A review. Bioresour. Technol. 51: 103–109.

Nigam, P. S. and A. Singh (2010) Production of liquid biofuels from renewable resources. Prog. Ener. Combust. Sci. 37: 52–68.

Zhang, L. Y., Yang, Y. L., Sun, J. A., Shen, Y. L., Wei, D. Z., Zhu, J. W., and Chu, J. (2010) Microbial production of 2,3-butanediol by a mutagenized strain of Serratia marcescens H3O. Bioresour. Technol. 101: 1961–1967.

Cheng, K. K., Q. Liu, and J. A. Zhang (2010) Improved 2,3-butanediol production from corncob acid hydrolysate by fedbatch fermentation using Klebsiella oxytoca. Proc. Biochem. 45: 613–616.

Wheat, J. A., J. D. Leslie, and R. V. Tomkins (1948) Production and properties of 2,3-butanediol: XXVIII. Pilot plant recovery of levo-2,3-butanediol from whole wheat mashes fermented by Aerobacillus polymyxa. Can. J. Resear. 26: 469–496.

Shao, P. and A. Kumar (2009) Recovery of 2,3-butanediol from water by a solvent extraction and pervaporation separation scheme. J. Membr. Sci. 329: 160–168.

Li, Z. G., H. Teng, and Z. L. Xiu (2010) Aqueous two-phase extraction of 2,3-butanediol from fermentation broths using an ethanol/ammonium sulfate system. Proc. Biochem. 45: 731–737.

Dai, J. Y., Y. L. Zhang, and Z. L. Xiu (2011) Salting out Extraction of 2,3-Butanediol from Jerusalem artichoke-based fermentation broth. Chin. J. Chem. Eng. 19: 682–686.

Senkus, M. (1946) Recovery of 2,3-butanediol produced by fermentation. Ind. Eng. Chem. 38: 913–916.

Xiang, B. T., S. F. Chen, and D. H. Liu (2001) Extraction of 1,3-propanediol in dilute fermentation broth. J. Tsinghua Uni. 41: 53–55.

Xiu, Z. L. and A. P. Zeng (2008) Present state and perspective of downstream processing of biologically produced 1,3-propanediol and 2,3-butanediol. Appl. Microbiol. Biotechnol. 6: 917–926.

Hao, J., F. Xu, H. J. Liu, and D. H. Liu (2006) Downstream processing of 1,3-propanediol fermentation broth. J. Chem. Technol. Biotechnol. 81: 102–108.

Zhang, L., Z. M. Xiu, and X. Q. Yuan (2000) Elements of chemical reaction engineering. 1st ed., pp. 28–43. East China University of Science and Technology Press, Shanghai, China.

Xie, Z. M., W. M. Zhang, and L. M. Zhang (2009) Basic Chemistry. 2nd ed., pp 67–98. Science Press, Beijing, China.

Wu, B., J. W. Zhu, and L. J. Ji (2003) Use of long-chain alcohol in extraction and purification of Licomycin from fermentation broth. Kor. J. Chem. Eng. 20: 354–358.

Wang, X. P. and Xing, S. L. (2009) Determination of protein quantitation using method of coomassie brilliant blue. Tianjin Chem. Ind. 23(3): 40–42.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Wu, Y., Zhu, J. et al. Separation of 2,3-butanediol from fermentation broth by reactive-extraction using acetaldehyde-cyclohexane system. Biotechnol Bioproc E 17, 337–345 (2012). https://doi.org/10.1007/s12257-011-0675-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-011-0675-5