Abstract

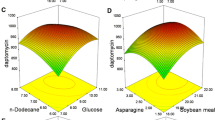

To produce 1,3-propanediol (1,3-PD) from crude glycerol, cultivation conditions were optimized by response surface methodology (RSM) based on a 25 factorial central composite design (CCD). RSM was adopted to derive a statistical model for the individual and interactive effects of crude glycerol, (NH4)2SO4, pH, cultivation time and temperature on the production of 1,3-PD. Optimal conditions for maximum 1,3-PD production were as follows: crude glycerol, 35 g/L; (NH4)2SO4, 8 g/L; pH, 7.37; cultivation time, 10.8 h; temperature, 36.88°C. Under these optimal conditions, the design expert presented the maximal numerical solution with a predicted 1,3-PD production level of up to 13.74 g/L. The experimental production of 1,3-PD yielded 13.8 g/L, which was in close agreement with the model prediction.

Similar content being viewed by others

References

Huang, H., C. S. Gong, and G. T. Tsao (2002) Production of 1,3-propanediol by Klebsiella pneumoniae. Appl. Biochem. Biotechnol. 98–100: 687–698.

Zeng, A. P. and H. Biebl (2002) Bulk chemicals from biotechnology: the case of 1,3-propanediol production and the new trends. Adv. Biochem. Eng. Biotechnol. 74: 239–259.

El-Ziney, M. G., N. Arneborg, M. Uyttendaele, J. Debevere, and M. Jakobsen (1998) Characterization of growth and metabolite production of Lactobacillus reuteri during glucose/glycerol cofermentation in batch and continuous cultures. Biotechnol. Lett. 20: 913–916.

Houng, J. Y., K. C. Chen, and W. H. Hsu (1989) Optimization of cultivation medium composition for isoamylase production. Appl. Microbiol. Biotechnol. 31: 61–64.

Reimann, A., H. Biebl, and W. D. Deckwer (1998) Production of 1,3-propanediol by Clostridium butyricum in continuous culture with cell recycling. Appl. Microbiol. Biotechnol. 49: 359–363.

Biebl, H. (1991) Glycerol fermentation of 1,3-propanediol by Clostridium butyricum. Measurement of product inhibition by use of a pH-auxostat. Appl. Microbiol. Biotechnol. 35: 701–705.

Forsberg, C. W. (1987) Production of 1,3-propanediol from glycerol by Clostridium acetobutylicum and other Clostridium species. Appl. Environ. Microbiol. 53: 639–643.

Mu, Y., H. Teng, D. J. Zhang, W. Wang, and Z. L. Xiu (2006) Microbial production of 1,3-propandiol by Klebsiella pneumoniae using crude glycerol from biodiesel preparations. Biotechnol. Lett. 28: 1755–1759.

Biebl, H., A. P. Zeng, K. Menzel, and W. D. Deckwer (1998) Fermentation of glycerol to 1,3-propanediol and 2,3-butanediol by Klebsiella pneumoniae. Appl. Microbiol. Biotechnol. 50: 24–29.

Box, G. E. P., W. G. Hunter, and J. S. Hunter (1978) Statistic for Experimenters: An Introduction to Design, Data Analysis, and Model Building. John Wiley and Sons Inc., New York, NY, USA.

Box, G. E. P. and K. B. Wilson (1951) On the experimental attainment of optimum conditions. J. R. Stat. Soc. Ser B 13: 1–45.

Preetha, R., N. S. Jayaprakash, R. Philip, and I. S. Bright Singh (2007) Optimization of medium for the production of a novel aquaculture probiotic, Micrococcus MCCB 104 using central composite design. Biotechnol. Bioprocess Eng. 12: 548–555.

Shi, F., Z. Xu, and P. Cen (2006) Optimization of γ-polyglutamic acid production by Bacillus subtilis ZJU-7 using a surface-response methodology. Biotechnol. Bioprocess Eng. 11: 251–257.

Zheng, Z. M., Q. L. Hu, J. Hao, F. Xu, N. N. Guo, Y. Sun, and D. H. Liu (2008) Statistical optimization of culture conditions for 1,3-propanediol by Klebsiella pneumoniae AC 15 via central composite design. Bioresour. Technol. 99: 1052–1056.

Chen, H., B. Fang, and Z. Hu (2007) Simultaneous HPLC determination of four key metabolites in the metabolic pathway for production of 1,3-propanediol from glycerol. Chromatographia 65: 629–632.

Zheng, S., K. Friehs, N. He, X. Deng, Q. Li, Z. He, C. Xu, and Y. Lu (2007) Optimization of medium components for plasmid production by recombinant E. coli DH5α pUK21CMVβ1.2. Biotechnol. Bioprocess Eng. 12: 213–221

Min, B. J., Y. S. Park, S. W. Kang, Y. S. Song, J. H. Lee, C. Park, C. W. Kim, and S. W. Kim (2007) Statistical optimization of medium components for the production of xylanase by Aspergillus niger KK2 in submerged cultivation. Biotechnol. Bioprocess Eng. 12: 302–307.

Mundra, P., K. Desai, and S. S. Lele (2007) Application of response surface methodology to cell immobilization for the production of palatinose. Bioresour. Technol. 98: 2892–2896.

Paul, G. C., C. A. Kent, and C. R. Thomas (1992) Quantitative characterization of vacuolization in Penicillium chyrsogenum using automatic image analysis. Trans. IChemE. 70: 13–20.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oh, BR., Seo, JW., Choi, M.H. et al. Optimization of culture conditions for 1,3-propanediol production from crude glycerol by Klebsiella pneumoniae using response surface methodology. Biotechnol Bioproc E 13, 666–670 (2008). https://doi.org/10.1007/s12257-008-0090-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-008-0090-8