Abstract

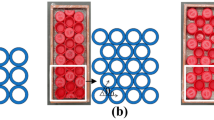

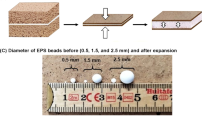

This is the first attempt to combine disposed bottle caps and natural fibres into sandwich panels. A full factorial design is performed to identify the effects of the skin type (aluminium or coir fibre reinforced laminates) and bottle cap core packing (cubic and orthotropic) on the mechanical properties of the proposed panels. The coir fibre composite skin provides maximum core shear strength, 29 % higher than the aluminium-based panels, in cubic packing, while the flexural modulus is reduced by 45 %. An interlocking effect between the skin and the core is evidenced when coir fibre composites are used. In addition, the cubic cell packing increases the specific mechanical properties, even though with a higher density. The results highlight a promising association of green components and plastic bottle caps for secondary structural applications.

Similar content being viewed by others

References

T. Bitzer, “Honeycomb Technology: Materials, Design, Manufacturing, Applications and Testing”, Chapman & Hall, London, 1997.

P. R. Oliveira, A. M. S. Bonaccorsi, T. H. Panzera, A. L. Christoforo, and F. Scarpa, Thin-Walled Struct., 120, 38 (2017).

P. R. Oliveira, T. H. Panzera, R. T. Freire, and F. Scarpa, Thin-Walled Struct., 130, 362 (2018).

N. Cabrera, B. Alcock, and T. Peijs, Compos. Part B-Eng., 39, 1183 (2008).

A. J. Babafemi, B. Šavija, S. Paul, and V. Anggraini, Sustainability, 10, 3875 (2018).

L. M. G. Vieira, J. C. D. Santos, T. H. Panzera, J. C. C. Rubio, and F. Scarpa, Ind. Crop. Prod., 99, 189 (2017).

M. R. Sanjay, P. Madhu, M. Jawaid, P. Senthamaraikannan, S. Senthil, and S. Pradeep, J. Cleaner Prod., 172, 566 (2018).

R. Hoto, G. Furundarena, J. Torres, E. Muñoz, J. Andrés, and J. García, Mater. Lett., 127, 48 (2014).

T. Liu, S. Hou, X. Nguyen, and X. Han, Compos. Part B-Eng., 114, 328 (2017).

P. Sadeghian, D. Hristozov, and L. Wroblewski, J. Sandwich Struct. Mater., 20, 287 (2016).

K. E. Chan, L. A. Yong, Y.-F. Ko, and S. Mendez, J. Sandwich Struct. Mater., 19, 192 (2016).

S. Rao, K. Jayaraman, and D. Bhattacharyya, Compos. Part B-Eng., 43, 2738 (2012).

S. Rao, R. Das, and D. Bhattacharyya, Compos. Part A-Appl. Sci. Manuf., 45, 6 (2013).

J. Grünewald, P. Parlevliet, and V. Altstädt, J. Therm. Compos. Mater., 30, 437 (2016).

M. Z. Hassan, R. Umer, S. Balawi, and W. J. Cantwell, J. Compos. Mater., 48, 3083 (2013).

N. J. Recycling, Bottle Cap Recycling (Plastic and Metal) in New Jersey. Available at: http://www.recyclingnj.com/recycle/caps.html. (Accessed June 14, 2019).

Marine Conservation Society. Great British Beach Clean — 2017 Report. Available at: https://www.mcsuk.org/media/GBBC_2017_Report.pdf. (Accessed June 14, 2019).

British Parliament — House of Commons: Environmental Audit Committee. Plastic bottles: Turning Back the Plastic Tide (First Report of Session 2017–19). Available at: https://publications.parliament.uk/pa/cm201719/cmselect/cmenvaud/339/339.pdf. (Accessed June 14, 2019).

K. Seaver,’ 360: Bottle Caps’. Earth911. Available from: http://www.earth911.com/food/360-bottle-caps/. (Accessed June 14, 2019).

CEMPRE — Compromisso Empresarial para a Reciclagem. Pesquisa Ciclosoft, (2016) (in Portuguese). Available at: http://cempre.org.br/ciclosoft/id/8. (Accessed June 14, 2019).

L. L. Hu, X. L. He, G. P. Wu, and T. X. Yu, Int. J. Impact Eng., 75, 150 (2015).

T. C. Lin, T. J. Chen, and J. S. Huang, Compos. Sci. Technol., 72, 1380 (2012).

R. Oruganti and A. Ghosh, Acta Materialia, 56, 726 (2008).

T. P. Gotkhindi and K. Simha, Int. J. Mech. Sci., 76, 70 (2013).

International Organization for Standardization, “ISO 209: Aluminium and Aluminium Alloys — Chemical Composition”, 2007.

Minitab Inc., “Minitab 17 Statistical Software”, State College, PA, 2010.

ASTM International, “D3933: Standard Guide for Preparation of Aluminum Surfaces for Structural Adhesives Bonding (Phosphoric Acid Anodizing)”, West Conshohocken, USA, 2010.

L. A. D. Olveira, J. C. D. Santos, T. H. Panzera, R. T. S. Freire, L. M. G. Vieira, and J. C. C. Rubio, Polym. Polym. Compos., 26, 391 (2018).

ASTM International, “D3039: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials”, West Conshohocken, USA, 2017.

ASTM International, “D792: Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement”, West Conshohocken, USA, 2013.

M. M. Jesus, P. R. Oliveira, S. L. M. Ribeiro Filho, M. L. P. Tonatto, and T. H. Panzera, “Proceedings of the 4th Brazilian Conference on Composite Materials (BCCM4)”, pp.807–817, Rio de Janeiro, 2018.

ASTM International, “C393/C393M-11: Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure”, West Conshohocken, USA, 2011.

ASTM International, “D7250: Standard Practice for Determining Sandwich Beam Flexural and Shear Stiffness”, West Conshohocken, USA, 2016.

ASTM International, “D790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials”, West Conshohocken, USA, 2015.

D. C. Montgomery, “Introduction to Statistical Quality Control”, John Wiley & Sons, Inc., 6th Edition (978-0470169926), USA, 2008.

M. F. Ashby, “Materials Selection in Mechanical Design”, Elsevier, Oxford, 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Acnowledgments

The authors would like to thank the Brazilian Research Agencies, CNPq (PP-309885/2019-1, PhD Scholarship GDE no. 290224/2017-9) and FAPEMIG (PPM-00075-17) and CAPES (MSc scholarship), for the financial support provided.

Rights and permissions

About this article

Cite this article

Oliveira, P.R., dos Santos, J.C., Ribeiro Filho, S.L.M. et al. Eco-friendly Sandwich Panel Based on Recycled Bottle Caps Core and Natural Fibre Composite Facings. Fibers Polym 21, 1798–1807 (2020). https://doi.org/10.1007/s12221-020-9818-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9818-7