Abstract

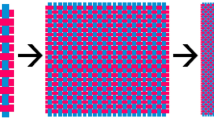

The study investigated the differences between perceived and instrumentally measured colors of woven fabrics in which different colored yarns are woven together such that they are perceived as solid colors. Cyan, magenta, and yellow yarns were woven together to produce 63 fabrics in a wide range of colors, the values of which were measured spectrophotometrically. The measured colors were generated as solid color images on a calibrated cathode ray tube (CRT) monitor. Then the fabrics were scanned and their scanned images were displayed beside their corresponding solid color images on the CRT monitor to evaluate the visual color difference between them. The results showed that the individual yarn colors and their interlacement on the fabric surface influenced the overall color appearance. Although the woven and solid colors in each pair had identical CIELAB color values, the perceived color difference was as large as 5.68 ΔE*ab,10 on average. Fabrics composed of various colors of yarn were found to have larger visual color differences from their measured colors than those composed of single colors of yarn. The visual color difference varied according to texture, but texture strength, which has been widely reported as a strong parametric factor in visual color difference evaluation, was not shown to have had a consistent effect. This study also examined how the overall color attributes, including the lightness, chroma, and hue, of fabrics affected the visual color difference and developed a predictive model of those effects.

Similar content being viewed by others

References

J. H. Xin, “Total Colour Management in Textiles”, pp. 57–75, Woodhead Publishing Ltd., Cambridge, 2006.

M. D. Fairchild, “Color Appearance Models”, 2nd ed., pp. 83–84, John Wiley & Sons Ltd., Chichester, 2005.

K. M. Tsang, Ph. D. Dissertation, The Hong Kong Polytechnic University, Hong Kong, 2016.

J. H. Xin, H. L. Shen, and C. C. Lam, Color Res. Appl., 30, 341 (2005).

S. J. Shao, J. H. Xin, Y. Zhang, and L. M. Zhou, AATCC Rev., 6, 42 (2006).

S. G. Kandi, M. A. Tehran, and M. Rahmati, Color. Technol., 124, 348 (2008).

J. H. Xin and H. L. Shen, J. Electron. Imaging, 12, 697 (2003).

Y. Chae, J. H. Xin, and T. Hua, Color Res. Appl., 41, 64 (2016).

Y. Chae, J. H. Xin, T. Hua, and M. Luo, Color Res. Appl., 42, 512 (2017).

M. F. A. Becky Koenig, “Color Workbook”, 4th ed., Pearson, New Jersey, 2012.

Y. Chae, J. H. Xin, and T. Hua, Color Res. Appl., 43, 130 (2018).

Y. Chae, J. Korean Soc. Cloth. Text., 42, 503 (2018).

K. Dimitrovski and H. Gabrijelcic, Tekstil, 50, 558 (2001).

H. Gabrijelcic and K. Dimitrovski, Tekstilec, 51, 30 (2008).

H. Gabrijelcic and K. Dimitrovski, Color. Technol., 125, 74 (2009).

A. F. M. Seyam and K. Mathur, Fiber. Polym., 13, 795 (2012).

Y. Chae, J. Korean Soc. Cloth. Text., 43, 373 (2019).

Fastness Tests Co-ordinating Committee, J. Soc. Dyers Colour., 69, 404 (1953).

S. Guan and M. R. Luo, Color Res. Appl., 24, 331 (1999).

M. Melgosa, J. Martínez-García, L. Gómez-Robledo, E. Perales, F. M. Martínez-Verdú, and T. Dauser, Opt. Express, 22, 3458 (2014).

AATCC EP 1:2007, “Gray Scale for Color Change”, 2007.

ISO 105-A02:1993, “Grey Scale for Assessing Change in Colour”, 1993.

S. Ishihara, “Tests for Colour-Blindness 24 Plates”, Kanehara Shuppan Co., Ltd., Tokyo, 1962.

D. Farnsworth, J. Opt. Soc. Am., 33, 568 (1943).

R. S. Berns, “Billmeyer and Saltzman’s Principles of Color Technology”, 3rd ed., pp. 11–19, John Wiley & Sons Inc., New York, 2000.

M. B. Cranwell, B. Pearce, C. Loveridge, and A. C. Hurlbert, Invest. Ophthalmol. Vis. Sci., 56, 3171 (2015).

M. Melgosa, P. A. García, L. Gómez-Robledo, R. Shamey, D. Hinks, G. Cui, and M. R. Luo, J. Opt. Soc. Am. A, 28, 949 (2011).

E. D. Montag and R. S. Berns, Color Res. Appl., 25, 241 (2000).

S. J. Miller, “The Method of Least Squares”, Mathematics Department, Brown University, USA, 2006.

E. Weisstein, “Least Squares Fitting”, Wolfram MathWorld Web Resource, http://mathworld.wolfram.com/LeastSquaresFitting.html (Accessed October 23, 2018).

CIE 217:2016, “Recommended Method for Evaluating the Performance of Colour-difference Formulae”, 2016.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chae, Y., Hwang, J. Visual Color Difference between Colored-Yarn Mixed Woven Fabrics and Their Instrumentally Measured Colors: the Effects of Individual Yarn Colors and Texture. Fibers Polym 21, 792–802 (2020). https://doi.org/10.1007/s12221-020-9369-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9369-y