Abstract

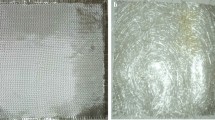

In this study, the influence of nanoclay on mechanical properties of epoxy/3D orthogonal glass fiber woven composite was studied. The DK2 polymer-grade organic nanoclay modification composite specimen reinforced with 3D orthogonal woven fabric/epoxy was manufactured by means of Resin Infusion under Flexible Tooling (RIFT) process. Firstly, the modification mechanism with nanoclay was characterized by means of Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD) and transmission electron microscope (TEM). Secondly, as far as the tensile behavior between the fiber/matrix of the composite was concerned, the modification process was optimized by means of nonlinear least square fitting. The results show that the bonding strength between the fiber and matrix was improved and the delamination and debonding between fiber and matrix was retarded and shifted to cohesive failure of the matrix due to the nanoclay modification with respect to results from FT-IR, XRD and TEM. The tensile strength and modulus of composite were increased by 23.32 % and 16.42 % respectively due to 3 of nanoclay addition. The contact angle also shows that the dispersion effect and wettability at this state. The tensile stress-strain curve was fitted by applying nonlinear fitting. It can be concluded that there has a good modification effect with 3 wt% of nanoclay addition.

Similar content being viewed by others

References

O. Stolyarov, T. Quadflieg, and T. Gries, Text. Res. J., 85, 1934 (2015).

K. Sharp, A. Bogdanovich, R. Boyle, J. Brown, and D. Mungalov, Compos. Part A-Appl. S., 49, 9 (2013).

X. Gao, N. Tao, X. Yang, C. Wang, and F. Xu, Compos. Part B-Eng., 159, 173 (2019).

X. Wang, H. Cao, and X. Huang, Ind. Text., 36, 7 (2018).

L. Yao, W. Li, N. Wang, W. Li, X. Guo, and Y. Qiu, J. Mater. Sci., 42, 6494 (2007).

K. Sharp and K. Davies, Reinf. Plast., 58, 52 (2014).

R. Jeyakumar, P. S. Sampath, R. Ramamoorthi, and T. Ramakrishnan, Int. J. Adv. Manuf. Tech., 93, 527 (2017).

H. Wang, X. Wang, and Z. Ding, Thermo. Resin., 33, 55 (2018).

P. Prabhu, S. Mohamed Iqbal, A. Balaji, and B. Karthikeyan, Adv. Compos. Hybrid Mater., 2, 93 (2019).

S. Li, Q. Lin, H. Zhu, C. Cui, H. Hou, T. Lv, and Y. Li, Fiber. Polym., 17, 282 (2016).

S. Erden, K. Sever, Y. Seki, and M. Sarikanat, Fiber. Polym., 11, 732 (2010).

M. Faruk, H. Sinin, M. Rezaur, M. Mizanur, F. Kiew, and J. Changhui, Fiber. Polym., 16, 479 (2015).

Ö. Y. Bozkurt, M. Bulut, A. Erklig, and W. A. Faydh, Compos. Part B-Eng., 158, 82 (2019).

M. Tomić, B. Dunjić, M. S. Nikolić, J. Maletaškić, V. B. Pavlović, J. Bajat, and J. Djonlagić, Appl. Clay Sci., 154, 52 (2018).

A. M. Elnaghy and S. E. Elsaka, Odontology, 104, 60 (2016).

N. Tao and X. Gao, Mod. Text. Tech., 27, 15 (2019).

P. Hari Sankar, Y. V. Mohana Reddy, and K. Hemachandra Reddy, Fiber. Polym., 16, 443 (2015).

R. Gokuldass and R. Ramesh, Silicon, https://doi.org/10.1007/s12633-018-0064-1 (2019).

W. Luo, X. Wang, R. Huang, and P. Fang, Wuhan Univ. J. Nat. Sci., 19, 34 (2014).

L. Gong, L. Hu, J. Zang, Y. Pei, L. Zhao, and L. Tang, Fiber. Polym., 16, 2056 (2015).

A. Yasmin, J. L. Abot, and I. M. Daniel, Scripta. Mater., 49, 81 (2003).

H. Park, P. Shin, J. Kim, Y. Baek, D. Kwon, W. Lee, K. L. DeVries, and J. Park, Fiber. Polym., 19, 1989 (2018).

Acknowledgements

This work was supported by The National Natural Science Foundation of China (Grant No. 51765051). The Natural Science Foundation of Inner Mongolia under grant No.2017MS0102, and the Open Project Program of Fujian Key Laboratory of Novel Functional Textile Fibers and Materials, Minjiang University, China (No.FKLTFM1807).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Gao, X. & Li, Y. Mechanical Properties Improvement of Nanoclay Addition Epoxy 3D Orthogonal Woven Composite Material. Fibers Polym 20, 1495–1503 (2019). https://doi.org/10.1007/s12221-019-9116-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-9116-4