Abstract

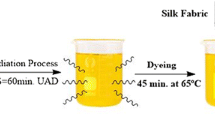

Dyeing is a state-of-the-art realm of textile engineering, however, the emphasis on petroleum-based products is now shifting towards green fibers, particularly, green manufacturing processes. In the present work, a natural mordant, sumac, was extracted and used alone and in combination with alum (a mineral mordant) in silk fibers dyeing with madder and Reseda green dye to make the green production of Iranian carpet possible. The FT-IR ATR spectra of the washed, mordanted, and mordanted dyed silk fibers revealed bonding between silk fibers and green materials. The color of the silk fibers dyed with madder and Reseda extraction was quantified in terms of CIELab (L*, a*, and b*) and K/S values. The effects of different treatments on fastness properties including light, wash, and rubbing fastness were assessed by ISO standard test method.

Similar content being viewed by others

References

M. Balter, Science, 325, 1329 (2009).

M. M. Hassan and M. Bhagranda, J. Cleaner Prod., 152, 464 (2017).

L. J. Rather, S. Islam, M. Shabbir, M. N. Bulchair, M. Shahid, M. A. Khan, and F. Mohammad, J. Environ. Chem. Eng., 4, 3041 (2016).

J. Shen, P. Gao, and H. Ma, Dyes Pigm., 108, 70 (2014).

W. Hadder, I. Elksibi, N. Meksi, and M. F. Mhenni, Ind. Crop. Prod., 52, 588 (2014).

Y. M. Indi, P. D. Patil, and T. D. Jujare, “Studies in Natural Dyeing (Part 2)”, Dye Chem. Pharma. Bus News, 42 (2016).

M. G. Uddin, J. Text., 2014, Article ID 405626 (2014).

A. Manhita, V. Ferreira, H. Vargas, I. Ribeiro, A. Candeias, D. Teixeira, T. Ferreira, and C. B. Dias, Microchem. J., 98, 182 (2011).

A. K. Samanta and P. Agarwal, Indian J. Fibre Text. Res., 34, 384 (2009).

S. Ul-Islam, L. J. Rather, M. Shabbir, J. Sheikh, M. N. Bukhar, M. A. Kan, and F. Mohammad, J. Nat. Fibers, doi: 10.1080/15440478.2018.1426080 (2018).

M. Shahid, S. Islam, and F. Mohammad, J. Cleaner Prod., 53, 310 (2013).

H. F. Mansour and S. Heffernan, Clean Technol. Environ. Policy, 13, 207 (2011).

M. Chairat, J. B. Bremner, and K. Chantrapromma, Fiber. Polym., 8, 613 (2007).

K. H. Prabhu and M. D. Teli, J. Saudi Chem. Soc., 18, 864 (2014).

L. J. Rather, S. Islam, M. Shabbir, M. N. Bukhar, F. Mohammad, and M. A. Khan, J. Nat. Fibers, doi:10.1080/15440478.2017.1349712 (2017).

L. J. Rather, M. A. Khan, and F. Mohammad, J. Nat. Fibers, doi:10.1080/15440478.2017.1414657 (2017).

K. Sachan and V. P. Kapoor, Indian J. Traditional Knowledge, 6, 270 (2007).

M. Chairat, U. Darumas, J. B. Bremner, and P. Bangrak, Color. Technol., 127, 346 (2011).

S. N. Chattopadhyay, N. C. Pan, A. K. Roy, S. Saxena, and A. Khan, J. Text. Inst., 104, 808 (2013).

A. Haji, Iranian J. Chem. Chem. Eng., 29, 5 (2010).

A. Guesmi, N. B. Hamadi, N. Ladhari, and F. Sakli, Ind. Crop. Prod., 37, 493 (2012).

A. Guesmi, N. Ladhari, N. B. Hamadi, and F. Sakli, Ind. Crop. Prod., 37, 342 (2012).

https://doi.org/www.internetrugs.com/blog/natural-dyes-and-syntheticdyes-in-oriental-rugs/, 2007.

M. Hosseinnezhad, K. Gharanjig, S. Belbasi, and S. H. Seied Saadati, Prog. Color Colorants Coat., 10, 129 (2017).

N. Jahan and S. E. Datta, IOSR J. Polym. Text. Eng., 2, 5 (2015).

M. Chairat, J. B. Bremner, and K. Chantrapromma, Fiber. Polym., 8, 613 (2007).

L. J. Rather, S. Islam, and F. Mohammad, Fiber. Polym., 16, 1497 (2015).

https://doi.org/wwwchem.uwimona.edu.jm/courses/CHEM2402/Textiles/Animal_Fibres.html

M. Yusuf, F. Mohammad, and M. Shahid, J. King Saud Univ., 29, 137 (2017).

M. Yusuf, S. A. Khan, M. Shabbir, and F. Mohammad, J. Nat. Fibers, 14, 597 (2017).

Y. Yin, J. Jia, and T. Wang, J. Cleaner Prod., 149, 637 (2017).

M. Hosseinnezhad, K. Gharanjig, S. Moradian, and S. Tafaghodi, Arabian J. Chem., https://doi.org/10.1016/j.arabjc.2014.12.027 (2015).

M. Yusuf, F. Mohammad, M. Shabbir, and M. A. Khan, Text. Clot. Sustain., 2, 10 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseinnezhad, M., Gharanjig, K., Belbasi, S. et al. The Use of Sumac as a Natural Mordant in Green Production of Iranian Carpet. Fibers Polym 19, 1908–1912 (2018). https://doi.org/10.1007/s12221-018-7961-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-018-7961-1