Abstract

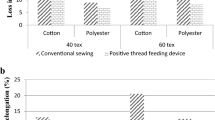

In this study, the role and impact of silver nanoparticles on industrial sewing threads have been investigated. Study of nanocoating on industrial sewing threads may be useful especially in the areas where skin comes in contact with the garments where anti-bacterial properties may be very useful. Silver particles are considered to have excellent anti bacterial properties. To understand the impact on sewability, investigation was focused to changes at the structural level, changes in physical and surface properties, tensile properties and anti-microbial properties of the nanotreated sewing threads. The structure and morphology of the silver nanoparticles on the sewing threads was observed by scanning electron microscopy (SEM) and quantitatively confirmed by fourier transform infrared spectroscopy (FT-IR). A number of experimental methods and mathematical formulae were used to test individual threads. Custom designed fixtures were used for the study. All the results have been statistically analyzed and found to be significant. The effect of silver nanoparticles on physical properties, functional properties and seam efficiency was illustrated. The difference of the impact of silver nanoparticles on cotton and polyester sewing threads has been compared. It was found that silver nanotreatment leads to a significant reduction of tensile strength. The warp-way seam strength increased where as weft-way seam strength decreased due to damage of yarn. Deformation properties of the threads are not influenced significantly by nanotreatment. The nanotreatment of threads improves its frictional properties significantly. The threads also acquire effective anti-microbial properties with silver nanotreatment. Study of the impact of nanotreatment on the properties of cotton and polyester samples showed a bigger impact on cotton samples than polyester samples. The effect was durable even after several laundering treatments.

Similar content being viewed by others

References

V. Dobilaite and M. Juciene, Int. J. Cloth. Sci. Tech., 18, 335 (2006).

G. Mansoori, J. ASTM Int., 2, 6 (2005).

D. Chattopadhyay and B. H. Patel, Ind. J. Fibre. Text., 34, 368 (2009).

I. H. Al-Shibi, Pakistan Text. J., 11, 48 (2013).

M. G. Guzman, J. Dille, and S. Godet, World Academy Sci. Eng. Tech., 43, 357 (2008).

P. W. Carlene, J. Text. Inst., 41, T159 (1950).

Standard Test Method for Coefficient of Friction, Yarn to Yarn, ASTM D 3412 — 01, 2001.

Standard Test Method for Colorfastness and Transfer of Color in the Washing, ASTM D2096 — 11, 2011.

S. Debnath and S. Sengtupta, Ind. J. Fibre. Text., 34, 11 (2009).

G. Bhatt, R. R. Hegde, M. G. Kamath, and B. Deshpande, J. Eng. Fiber. Fabr., 3, 3 (2008).

L. Qian and J. P. Hinestroza, J. Text. Appl. Tech. Mgmt., 4, 1 (2004).

M. S. Kannan and A. Kumar, Ind. Text. J., 58, 25 (2009).

Y. W. H. Wong, C. W. M. Yuen, M. Y. S. Leung, S. K. A. Ku, and H. L. I. Lam, AUTEX Res. J., 6, 1 (2006).

S. Kathirvelu, L. D’Souza, and B. Dhurai, Ind. J. Fibre. Text., 34, 267 (2009).

C. Chinkap, L. Myunghee, and K. C. Eun, Carbohyd. Polym., 58, 417 (2004).

R. M. El-Shishtawy, A. M. Asiri, N. A. M. Abdelwahed, and M. M. Al-Otaibi, Cellulose, 18, 75 (2011).

M. Mori and M. Niwa, Int. J. Cloth. Sci. Tech., 6, 20 (1994).

D. West, Text. Asia, 24, 82 (1993).

S. D. Pai, V. G. Munshi, and A. V. Ukidve, Text. Asia, 15, 80 (1984).

J. Fan and W. Leeuwner, J. Text. Inst., 89, 142 (1998).

J. O. Ukponmwan, Text. Progress, 30, 79 (2000).

A. K. Singh, R. K. Gaur, and J. Prakash, Ind. Text. J., 104, 70 (1994).

S. D. Pai, V. G. Munshi, and A. V. Ukidve, Text. Res. J., 52, 776 (1982).

L. Maleknia, A. A. Aala, and K. Yousefi, Asian J. Chem., 22, 5925 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Venkataraman, M., Mishra, R., Subramaniam, V. et al. Application of silver nanoparticles to industrial sewing threads: Effects on physico-functional properties & seam efficiency. Fibers Polym 15, 510–518 (2014). https://doi.org/10.1007/s12221-014-0510-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-0510-7