Abstract

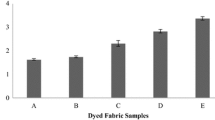

Although madder (Rubia tinctorum) has been used as a well-known natural textile dye source for dyeing of natural fibers such as wool, silk and cotton, 100 % polyester dyeing with madder is not common. In this study, polyester samples were dyed with madder at different dyeing temperatures, from 60 °C to 130 °C, in company with 7 chemical and 5 natural mordants. Color properties and rub, light and wash fastness performances were investigated. Different shades of orange, brown, pink and reddish green colors were obtained. Dyeing at 130 °C exhibited the highest color yield, the highest chroma and the lowest lightness values. Overall, chemical mordants exhibited higher color yields than natural mordants. High wash fatness, moderate light and rub fastness levels were observed. The potassium bitartrate and gallnut, a natural mordant, exhibited the best results. The madder dyeing of polyester should be carried out at hot temperature conditions, 130 °C, in order to obtain the highest achievable color yield and chroma with the highest light and wash fastness properties.

Similar content being viewed by others

References

R. S. Blackburn, “Biodegradable and Sustainable Fibers”, Woodhead Publishing Limited, 2005.

H. Ludewig, “Polyester Fibers Chemistry and Technology”, Wiley-Interscience, 1971.

W. Ingamells, “Colour for Textiles a User’s Handbook”, Society of Dyers and Colourists, 1993.

D. Broadbent, “Basic Principles of Textile Coloration”, Society of Dyers and Colourists, 2001.

M. Lewin and E. M. Pearce, “Handbook of Fiber Science and Technology: Volume IV Fiber Chemistry”, Marcel Dekker Inc., 1985.

R. A. Auras, B. Harte, S. Selke, and R. J. Herandez, “WMU Barrier Coating Symposium”, Michigan, USA, 2002.

C. Hawkyard, “Synthetic Fiber Dyeing”, Society of Dyers and Colorists, 2004.

J. R. Aspland, Text. Chem. Color., 24, 36 (1992).

D. M. Nunn, “The Dyeing of Synthetic-polymer and Acetate Fibers”, Dyers Company Publications Trust, 1979.

D. R. Waring and G. Hallas, “The Chemistry and Application of Dyes”, Plenum Press, New York, 1994.

K. Farizadeh, M. E. Yazdanshenas, M. Montazer, R. M. A. Malek, and A. Rashidi, Text. Res. J., 80, 847 (2010).

D. De Santis and M. Moresi, Ind. Crop. Prod., 26, 151 (2007).

O. Stallmann, J. Chem. Ed., 37, 220 (1960).

P. Banyai, I. N. Kuzovkina, L. Kursinszki, and É. Szöke, Chromatographia, 63, 111 (2006).

T. Bechtold and R. Mussak, “Handbook of Natural Colorants”, John Wiley & Sons, Ltd., 2009.

R. Räisänen, P. Nousiainen, and P. H. Hynninen, Text. Res. J., 71, 922 (2001).

D. Gupta, S. Kumari, and M. Gulrajani, Color. Technol., 117, 328 (2001).

D. Gupta, S. Kumari, and M Gulrajani, Color. Technol., 117, 333 (2001).

S. Ali, T. Hussain, and R. Nawaz, J. Clean. Prod., 17, 61 (2009).

R. Buhuyan, D. C. Saikia, and C. N. Saikia, Ind. J. Text. Fiber Res., 27, 429 (2002).

K. Farizadeh, M. Montazer, M. E. Yazdanshenas, R. M. A. Malek, A. Rashidi, R. Mohammed, and A. Malek, J. Appl. Polym. Sci., 113, 3799 (2009).

R. Räisänen, “Anthraquinones from the Fungus Dermocybe sanguinea as Textile Dyes”, Academic Dissertation, University of Helsinki, 2002.

A. K. Samanta, P. Agarwal, D. Singhee, and S. Datta, J. Text. Inst., 100, 565 (2009).

A. K. Samanta and P. Agarwal, Ind. J. Fiber Text. Res., 34 (2009).

P. Nilani, B. Duraisami, P. Dhamodaran, N. Kasthuribai, A. Semwol, and B. Suresh, J. Pharm. Res., 1, 2 (2008).

R. Räisänen, P. Nousiainen, and P. H. Hynninen, Text. Res. J., 71, 1016 (2001).

Y. H. Lee, J. Appl. Polym. Sci., 103, 251 (2007).

H. T. Deo and B. K. Desai, J. Soc. Dyers Colour., 115, 224 (1999).

L. Wang, J. Li, and H. Feng, Pigm. Resin Technol., 38, 347 (2009).

R. Zhang and Z. Cai, Fiber. Polym., 12, 478 (2011).

E. Yi and Y. Rhee, Fiber. Polym., 10, 200 (2009).

N. Ino, T. Tanaka, A. Okumura, Y. Morishita, H. Makita, Y. Kato, M. Nakamura, and H. Mori, Toxicology and Industrial Health, 11, 449 (1995).

E. P. A. Kumbasar, “Natural Dyes”, InTech, 2011.

E. S. B. Ferreira, A. N. Hulme, H. McNab, and A. Quye, Chem. Soc. Rev., 33, 329 (2004).

R. Mongkholrattanasit, J. Krystufek, J. Wiener, and J. Studnickova, Fibres Text. East. Eur., 19, 90 (2011).

Padma S Vankar, “Handbook on Natural Dyes for Industrial Applications”, National Institute of Industrial Research, 2007.

Ioannis Drivas, Richard S. Blackburn, and Christopher M. Rayner, Dyes and Pigments, 88, 7 (2011).

J. E. McIntyre, “Synthetic Fibers: Nylon, Polyester, Acrylic, Polyolefin”, Woodhead Publishing, 2005.

V. B. Gupta and V. K. Kothari, “Manufactured Fiber Technology”, 2nd ed., Chapman & Hall, London, 1997.

B. Wang, Z. F. Wang, M. Zhang, W. H. Liu, and S. J. Wang, Macromolecules, 35, 3993 (2002).

W. S. Perkins, “Textile Coloration and Finishing, Carolina Academic Press”, North Carolina, 1996.

A. K. Roy Choudhury, “Textile Preparation and Dyeing”, Science Publishers, US, 2006.

D. I. Bower, “An Introduction to Polymer Physics”, Cambridge University Press 2002.

http://www.sigmaaldrich.com (accessed on 04/04/2012).

http://www.chemblink.com (accessed on 04/04/2012).

T. Choi, Y. Shimizu, H. Shirai, and K. Hamada, Dyes and Pigments, 50, 55 (2001).

K. D. Clerck, H. Rahier, B. V. Mele, P. Westbroek, and P. Kiekens, J. Appl. Polym. Sci., 106, 1648 (2007).

K. D. Clerck, P. V. Oostveldt, H. Rahier, B. V. Mele, P. Westbroek, and P. Kiekens, Polymer, 45, 4105 (2004).

R. Atav and A. Delituna, Tekstil Teknolojileri Elektronik Dergisi — Electron. J. Text. Technol., 4, 73 (2010).

E. P. G. Gohl and L. D. Vilensky, “Textile Science, Second Edition”, Longman Cheshire, Australia, 1983.

P. C. Crews, Studies in Conservation, 32, 65 (1987).

D. Cristea and G. Vilarem, Dyes and Pigments, 70, 238 (2006).

D. Gupta, M. L. Gulrajani, and S. Kumari, Color. Technol., 120, 205 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gedik, G., Avinc, O., Yavas, A. et al. A novel eco-friendly colorant and dyeing method for poly(ethylene terephthalate) substrate. Fibers Polym 15, 261–272 (2014). https://doi.org/10.1007/s12221-014-0261-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-0261-5