Abstract

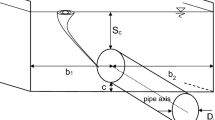

In order to recover casing gas efficiently and safely, a new scheme is proposed to recover casing gas by using an ejector. The influence of the nozzle diameter and the distance from nozzle to throat on the performance of the ejector under different working conditions is studied. The results show that when the nozzle diameter is constant, the inspiratory capacity increases with the increase of water pressure. Compared three nozzles with different diameters, the inspiratory capacity and water flow were approximately linear. Under different working fluid pressures, as the distance from nozzle to throat increases, the ejection ratio of the ejector first increases and then decreases, and there is an optimal distance. In the field test, the gas flow rate of the recovered casing is about 35.27 m3/h.

Similar content being viewed by others

References

W. Wang, X. Yan and H. Zhao, Gas production law of oil well casing annulus, Oil Drilling and Production Technology, 3 (2008) 52–55.

D. Cao, Z. Liu and L. Wu, Comprehensive utilization analysis of associated gas in oilfield, Petroleum and Naturalm Gas Chemical Industry, 44(2) (2015) 60–64.

X. Xu, Y. Xu and W. Zhang, Recovery and utilization of associated gas in crude oil production process, China and Foreign Energy, 24(5) (2019) 91–96.

D. Xu and L. Ma, Current situation and analysis of associated gas recovery device in oil field, Forum on Petroleum Science and Technology, 29(4) (2010) 29–33.

X. Su, S. Wang and L. Zhang, Countermeasures and current situation of oilfield associated gas utilization, Natural Gas and Petroleum, 2(2) (2008) 33–37.

Y. Song, Y. Cheng and R. Cheng, Development and application of wellhead constant pressure release valve, Oil and Gas Well Test, 14(2) (2005) 73–74.

T. Wu and Y. Tian, Research on recovery technology of casing gas in pumping wells, Yunnan Chemical Industry, 45(7) (2015) 138–140.

C. Li, Application of oil field associated gas recycling technology, Cleaning the World, 35(10) (2019) 48–49.

M. Petruccioli, J. C. Duarte and A. Eusebio, Aerobic treatment of winery wastewater using a jet-loop activated sludge reactor, Process Biochemistry, 37(8) (2002) 821–829.

B. Park, G. Hwang, S. Haam, C. Lee, I. Ahn and K. Lee, Absorption of a volatile organic compound by a jet loop reactor with circulation of a surfactant solution: performance evaluation, Journal of Hazardous Materials, 153(1) (2008) 735–741.

P. Zheng, B. Li and J. Qin, CFD simulation of two-phase ejector performance influenced by different operation conditions, Energy, 155(15) (2018) 1129–1145.

D. Sharma, A. Patwardhan and V. Ranade, Estimation of gas induction in jet loop reactors: influence of nozzle designs, Chemical Engineering Research and Design, 125(1) (2017) 24–34.

G. Li, Research on coal mining machine high-pressure drainage jet dust removal technology, Journal of Henan University of Science and Technology, 14(1) (2008) 75–81.

S. Taslimi Taleghani, M. Sorin, S. Poncet and H. Nesreddine, Performance investigation of a two-phase transcritical CO2 ejector heat pump system, Energy Conversion and Management, 185 (2019) 442–454.

H. Bian, W. Xu and X. Li, A new process for recovering associated gas condensates from oil fields using LNG cold energy, Chinese Journal of Chemical Engineering, 19(3) (2011) 452–461.

P. Fan, X. Wang and R. Jiang, Structural design of ejection injector and simulation analysis of off-site working conditions, Building Thermal Ventilation and Air Conditioning, 35(2) (2016) 49–52.

L. He, S. Wang and S. Wang, Experimental study on the influence of geometric structure parameters on the performance of injector, Cryogenic Engineering, 4(6) (2019) 6–11.

J. Wang, L. Han and D. Liu, Numerical simulation analysis of the influence of structural parameters on the performance of atmospheric ejector, Journal of Inner Mongolia Normal University (Chinese Version of Natural Science), 40(3) (2011) 243–245.

C. Yuan, L. Tao and G. Ma, Research on operation characteristics of solar jet refrigeration system, Light Industrial Machinery, 35(1) (2017) 10–13.

S. B. Riffat and S. A. Omer, CFD modelling and experimental investigation of an ejector refrigeration system using methanol as the working fluid, International Journal of Energy Research, 25(2) (2001) 115–128.

L. He, Y. Su and T. Jie, Structural design and performance analysis of gas-liquid ejector, Chemical Engineering Progress, 39(4) (2020) 1245–1251.

L. Cao and S. Bi, Numerical study on the effect of operating parameters on the performance of the injector, Journal of Northeast Dianli University, 38(4) (2015) 47–52.

Author information

Authors and Affiliations

Corresponding author

Additional information

J. Y. Zhao received a Master’s degree in Mechanical Engineering from China University of Petroleum (East China), and he is an Associate Professor. His main research interests include fluid mechanics and energy utilization, mechanical design, and petroleum mechanical engineering.

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhao, J., Liu, Z. et al. Numerical simulation and parameter study of ejector in casing gas recovery system. J Mech Sci Technol 35, 2689–2696 (2021). https://doi.org/10.1007/s12206-021-0539-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0539-7