Abstract

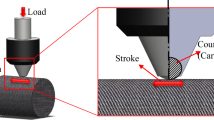

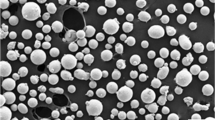

316L stainless steel specimens were manufactured by additive/subtractive hybrid manufacturing (ASHM). The densification level, mi-crostructure, microhardness and residual stress characterization in the different zones of the part were investigated. The density was determined by the Archimedes method, and the density measurement was divided into three regions, namely, the bottom, middle and top zones. The results show that the middle zone has a much smoother melting surface and that a relative density of nearly 100 % was achieved for the part in this study. The hardness profiles at room temperature, along the width and height directions of the cross-section of the top and bottom zones, were also studied. The residual stress was evaluated by X-ray diffraction (XRD) for the 316L SS specimen fabricated by the ASHM process, and it was compared with a specimen manufactured by the additive laser directed energy deposition (DED) process. The results show that the top and bottom zones exhibit tensile stress, and compressive stress occurs in the middle area. Moreover, the residual stress of ASHM shows a slightly smaller trend than that of the simplex DED due to the stress relaxation of the subsequent subtractive milling. These results may offer guidance for ASHM-fabricated 316L parts.

Similar content being viewed by others

References

C. L. Qiu, N. J. E. Adkins and M. M. Attallah, Selective laser melting of Invar 36: Microstructure and properties, Acta Materialia, 103 (2016) 382–395.

G. T. Gray, V. Livescu, P. A. Rigg, C. P. Trujillo, C. M. Cady, S. R. Chen, J. S. Carpenter, T. J. Lienert and S. J. Fen-sin, Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel, Acta Mate-rialia, 138 (2017) 140–149.

E. M. Lee, G. Y. Shin, H. S. Yoon and D. S. Shim, Study of the effects of process parameters on deposited single track of M4 powder based direct energy deposition, Journal of Mechanical Science and Technology, 31 (7) (2017) 3411–3418.

N. A. Kistler, D. J. Corbin, A. R. Nassar, E. W. Reutzel and A. M. Beese, Effect of processing conditions on the micro-structure, porosity, and mechanical properties of Ti-6A1-4V repair fabricated by directed energy deposition, Journal of Materials Processing Technology, 264 (2019) 172–181.

N. J. Harrison, I. Todd and K. Mumtaz, Reduction of micro-cracking in nickel superalloys processed by selective laser melting: A fundamental alloy design approach, Acta Materi-alia, 94 (2015) 59–68.

P. Mercelis and J. P. Kruth, Residual stresses in selective laser sintering and selective laser melting, Rapid Prototyping Journal, 12 (5) (2006) 254–265.

B. Almangour, D. Grzesiak, T. Borkar and J. M. Yang, Den-sification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selective laser melting, Materials and Design, 138 (2018) 119–128.

T. Zhan, F. Chai, J. Zhao, F. Yan and W. Wang, A study of microstructures and mechanical properties of laser welded joint in GH3030 alloy, Journal of Mechanical Science and Technology, 32 (6) (2018) 2613–2618.

H. Paris, H. Mokhtarian, E. Coatanea, M. Museau and I. F. Ituarte, Comparative environmental impacts of additive and subtractive manufacturing technologies, Cirp Annals-manufacturing Technology, 65 (2106) 29–32.

V. T. Le, H. Paris and G. Mandil, Process planning for combined additive and subtractive manufacturing technologies in a remanufacturing context, Journal of Manufacturing Systems, 44 (2017) 243–254.

K. L. Basinger, G. B. Keough, C. E. Webster, R. A. Wysk, T. M. Martin and O. L. Harrysson, Development of a modular computer-aided process planning (CAPP) system for ad-ditive-subtractive hybrid manufacturing of pockets, holes, and flat surfaces, International Journal of Advanced Manufacturing Technology, 92 (2018) 4367–4377.

J. Y. Liu, X. J. Wang and Y. Wang, A complete study on satellite thruster structure (STS) manufactured by a hybrid manufacturing (HM) process with integration of additive and subtractive manufacture, International Journal of Advanced Manufacturing Technology, 92 (2017) 4367–4377.

Z. C. Zhu, V. Dhokia, A. Nassehi and S. T. Newman, Investigation of part distortions as a result of hybrid manufacturing, Robotics and Computer-Integrated Manufacturing, 37 (2016) 23–32.

M. Soshi, J. Ring, C. Young, Y. Oda and M. Mori, Innovative grid molding and cooling using an additive and subtractive hybrid CNC machine tool, Cirp Annals-manufacturing Technology, 66 (1) (2017) 401–404.

V. Le, H. Paris and G. Mandil, The development of a strategy for direct part reuse using additive and subtractive manufacturing technologies, Additive Manufacturing, 22 (2018) 687–699.

Y. A. Song, S. Park and S. W. Chae, 3D welding and milling: Part I-a direct approach for freeform fabrication of metallic prototypes, International Journal of Machine Tools and Manufacture, 45 (9) (2005) 1057–1062.

Y. A. Song, S. Park and S. W. Chae, 3D welding and milling: Part II-a direct approach for freeform fabrication of metallic prototypes, International Journal of Machine Tools and Manufacture, 45 (9) (2005) 1063–1069.

D. S. Choi, S. H. Lee, B. S. Shin, K. H. Whang, Y. A. Song, S. H. Park and H. S. Jee, Development of a direct metal free-form fabrication technique using CO2 laser welding and milling technology, Journal of Materials Processing Technology, 113 (1) (2001) 273–279.

M. L. Pace, A. Guarnaccio, P. Dolce, D. Mollica, G. P. Parisi, A. Lettino, L. Medici, V. Summa, R. Ciancio and A. Santagata, 3D additive manufactured 316L components microstructural features and changes induced by working life cycles, Applied Surface Science, 418 (2017) 437–445.

E. Liverani, S. Toschi, L. Ceschini and A. Fortunate, Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel, Journal of Materials Processing Technology, 249 (2017) 255–263.

E. R. Denlinger and P. Michaleris, Effect of stress relaxation on distortion in additive manufacturing process modeling, Additive Manufacturing, 12 (2016) 51–59.

C. Q. Huang, H. Li, J. X. Li, C. G. Luo and Y. B. Ni, Residual stress measurement on propellant tank of 2219 aluminum alloy and study on its weak spot, Journal of Mechanical Science and Technology, 31 (5) (2017) 2213–2220.

Y. X. Feng, T. P. Hung, Y. T. Lu, Y. F. Lin, F. C. Hsu, C. F. Lin, Y. C. Lu and S. Y. Liang, Residual stress prediction in laser-assisted milling considering recrystallization effects, International Journal of Advanced Manufacturing Technology, 102 (1-4) (2019) 393–402.

W. Akhtar, J. F. Sun and W. Y. Chen, Effect of machining parameters on surface integrity in high speed milling of super alloy GH4169/Inconel 718, Materials and Manufacturing Processes, 31 (5) (2016) 620–627.

Y. Ma, P. F. Feng, J. F. Zhang, Z. J. Wu and D. W. Yu, Prediction of surface residual stress after end milling based on cutting force and temperature, Journal of Materials Processing Technology, 235 (2016) 41–48.

B. Z. Li, X. H. Jiang, J. G. Yang and S. Y. Liang, Effects of depth of cut on the redistribution of residual stress and distortion during the milling of thin-walled part, Journal of Materials Processing Technology, 216 (2014) 223–233.

K. Salonitis, L. D'Alvise, B. Schoinochoritis and D. Chantzis, Additive manufacturing and post-processing simulation: Laser cladding followed by high speed machining, Journal of Materials Processing Technology, 85 (9-12) (2016) 2401–2411.

X. H. Xiong, H. O. Zhang and G. L. Wang, Metal direct prototyping by using hybrid plasma deposition and milling, Journal of Materials Processing Technology, 209 (2009) 124–130.

Y. Y. Yang, Y. D. Gong, S. S. Qu, Y. L. Rong, Y. Sun and M. Cai, Densification, surface morphology, microstructure and mechanical properties of 316L fabricated by hybrid manufacturing, International Journal of Advanced Manufacturing Technology, 97 (5-8) (2018) 2687–2696.

P. J. Withers and H. K. D. H. Bhadeshia, Residual stress. Part 1 - Measurement techniques, Materials Science and Technology, 17 (4) (2001) 355–365.

A. Yadollahi, N. Shamsaei, S. M. Thompson and D. W. Seely, Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel, Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 644 (2015) 171–183.

N. Nadammal, S. Cabeza, T. Mishurova, T. Thiede, A. Kromm, C. Seyfert, L. Farahbod, C. Haberland, J. A. Schneider and P. D. Portella, Effect of hatch length on the development of microstructure, texture and residual stresses in selective laser melted superalloy Inconel 718, Materials and Design, 134 (2017) 139–150.

M. Yakout, M. A. Elbestawi and S. C. Veldhuisi, Density and mechanical properties in selective laser melting of Invar 36 and stainless steel 316L, Journal of Materials Processing Technology, 266 (2019) 397–420.

K. Feng, Y. Chen, P. S. Deng, Y. Y. Li, H. X. Zhao, F. G. Lu, R. F. Li, J. Huang and Z. G. Li, Improved high-temperature hardness and wear resistance of Inconel625 coatings fabricated by laser cladding, Journal of Materials Processing Technology, 243 (2017) 82–91.

E. Liverani, S. Toschi, L. Ceschini and A. Fortunate, Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel, Journal of Materials Processing Technology, 249 (2017) 255–263.

Acknowledgments

The author wishes to thank the support of the National Natural Science Foundation of China (No. 51775100), the Fundamental Research Funds for the Central Universities (No. N180306001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Zhuhua Tan

Yuing Yang is currently a Ph.D. student at Northeastern University, China. His research interests include laser additive manufacturing and milling.

Yuing Yang is currently a Ph.D. student at Northeastern University, China. His research interests include laser additive manufacturing and milling.

Yadong Gong is currently a Professor and a Ph.D. candidate Supervisor at Northeastern University, China. His main research interests include grinding, digital manufacturing and laser additive manufacturing.

Shuoshuo Qu is currently a Ph.D. student at Northeastern University, China. His main research interests include grinding of ceramic matrix composites.

Bo Xin is currently a Ph.D. lecturer at Northeastern University, China. His research interests include laser additive manufacturing and milling.

Yunchao Xu is currently a Ph.D. student at Northeastern University, China. His main research interests include grinding of Nickel-based single crystal superalloy.

Yang Qi is currently a Ph.D. student at Northeastern University, China. His research interests include reliability design of NC machine tools.

Rights and permissions

About this article

Cite this article

Yang, Y., Gong, Y., Qu, S. et al. Additive/subtractive hybrid manufacturing of 316L stainless steel powder: Densification, microhardness and residual stress. J Mech Sci Technol 33, 5797–5807 (2019). https://doi.org/10.1007/s12206-019-1126-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-1126-z