Abstract

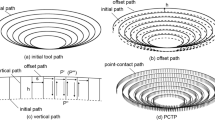

For the problem of the sheet distortion caused by the force of the two extrusion forming tools on the sheet in the double-sided CNC incremental forming, a point-pressing based double-sided CNC incremental forming was proposed in which the consecutive-extrusion of the extrusion forming tool on the sheet was replaced by the point-pressing. A point-pressing based double-sided CNC incremental forming toolpath generation algorithm based on the consecutive-extrusion based double-sided CNC incremental forming toolpath was presented. The double-sided CNC incremental forming processes based on the point-pressing and consecutive-extrusion was simulated by using the ANSYS/LS-DYNA software and the actual forming experiment. The numerical simulation results show that the double-sided CNC incremental forming based on the point-pressing compared with the process based on the consecutive-extrusion can acquire less circumferential displacement, less distortion, more evenly distributed average equivalent strain and less mutagenicity. It can be seen from the actual forming experiment that the sheet metal part formed by the point-pressing method has better geometric anastomosis with the design model than that formed by the consecutive-extrusion method.

Similar content being viewed by others

References

B. Lu, Y. Fang, D. K. Xu, J. Chen, S. Ai, H. Long, Ou and J. Cao, Investigation of material deformation mechanism in double side incremental sheet forming, International J. of Machine Tools and Manufacture, 93 (2015) 37–48.

A. K. Behera, R. A. D. Sousa, G. Ingarao and V. Oleksik, Single point incremental forming: An assessment of the progress and technology trends from 2005 to 2015, J. of Manufacturing Processes, 27 (2017) 37–62.

Y. Li, X. Chen, Z. B. Liu, J. Sun, F. Li, J. F. Li and G. Q. Zhao, A review on the recent development of incremental sheet-forming process, International J. of Advanced Manufacturing Technology, 92 (5-8). (2017) 2439–2462.

N. Moser, D. Pritchet, H. Ren, K. Ehmann and J. Cao, An efficient and general finite element model for double-sided incremental forming, J. of Mechanical Science and Technology, 138 (9) (2016) 091007-1-091007-10.

W. M. Yu and Z. Y. Chen, Experiment and design of double incremental forming device, Science Mosaic, 2 (2017) 81–86.

R. Lingam, O. Prakash, J. H. Belk and N. V. Reddy, Automatic feature recognition and tool path strategies for enhancing accuracy in double sided incremental forming, International J. of Advanced Manufacturing Technology, 88 (5-8) (2016) 1639–1655.

B. Valoppi, Z. X. Zhang, M. Y. Deng, A. Ghiotti, S. Bruschi, K. Ehmann and J. Cao. On the fracture characterization in double-sided incremental forming of Ti6A14V sheets at elevated temperatures, Procedia Manufacturing, 10 (2017) 407–416.

F. Tian, Study on the Influence of Forming Toolpath on the Progressive Forming of Sheet Metal, Chongqing University (2012).

J. Cao, Numerical Simulation and Forming Law of Sheet Metal Incremental Forming, Zhejiang University of Industry (2015).

X. D. Xiao, Y. J. Wang, J. C. Zhang and S. M. Wei, Experiment and simulation on sheet metal incrementally pressing forming, J. of Mechanical Engineering, 49 (16) (2013) 107–113.

Y. Fang, The Investigation of Deformation Mechanism and Process in Double Side Incremental Sheet Forming, Shanghai Jiao Tong University (2015).

S. Dejardin, S. Thibaud, J. C. Gelin and G. Michel, Experimental investigations and numerical analysis for improving knowledge of incremental sheet forming process for sheet metal parts, J. of Materials Processing Technology, 210 (2) (2010) 363–369.

G. Hussain, A. Mahna and A. Iqbal, Response surface analysis of cold formability of polymers in incremental sheet forming: Effect of parameters and associated thermal softening, International J. of Precision Engineering & Manufacturing, 17 (5) (2016) 613–621.

X. H. Zeng, J. H. Liu and G. R. Yan, Tool path generation based on STL data model, J. of Graphics, 23 (1) (2002) 8–14.

H. Zhu, J. Ju and W. Zhang, Generation and planning of the forming path for bump phenomenon in NC incremental forming, Forging & Stamping technology, 40 (5) (2015) 15–21.

R. Lingam, A. Bhattacharya, J. Asghar and N. V. Reddy, Compensations for tool path to enhance accuracy during double sided incremental forming, International Manufacturing Science and Engineering Conference (2015).

J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou and J. Allwood, Asymmetric single point incremental forming of sheet metal, CIRP Annals - Manufacturing Technology, 54 (2) (2005) 88–114.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

Hu Zhu is a Professor in the College of Mechanical and Electrical Engineering at Shenyang Aerospace University. He received his B.S. from Jilin University, and M.S. and Ph.D. in Mechanical Design and Production Engineering at Seoul National University. His current research interests include CAD/CAM, 3D printing, CNC incremental forming.

Dongxuan Xiao is currently an M.S. student of Mechanical and Electrical Engineering at Shenyang Aerospace University. He received his B.S. from Mechanical Manufacturing and Automation at Jilin Agricultural University. His research interests include CAD/ CAM, CNC incremental forming.

Jaeguan Kang is currently a Professor of Mechanical Engineering at Kyungnam University. He received his Ph.D. from Pohang University of Science and Technology, M.S. from Korea Advanced Institute of Science and Technology, B.S. from Seoul National University. His primary research interests include CAD/CAM, incremental sheet metal forming.

Rights and permissions

About this article

Cite this article

Zhu, H., Xiao, D. & Kang, J. Research on point-pressing based double-sided CNC incremental forming. J Mech Sci Technol 33, 4389–4400 (2019). https://doi.org/10.1007/s12206-019-0835-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0835-7