Abstract

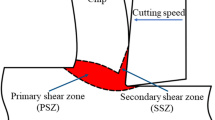

This work aims to develop a finite element model (FEM) for predicting machining-induced residual stresses. The effect of the constitutive model used to describe material response on the numerical modeling of orthogonal cutting is investigated. Two constitutive material models are separately incorporated into FEM: (i) The Johnson-Cook (JC) law and (ii) the proposed model, which considers kinematicisotropic hardening with strain rate and thermal softening effects. The influence of cyclic hardening on cutting forces, chip morphologies, and residual stresses (RS) is analyzed. Although the JC law produces superior results when modeling cutting forces and chip morphologies, the proposed model provides reliable results when predicting RS profiles.

Similar content being viewed by others

References

R. Grissa, F. Zemzemi and R. Fathallah, Three approaches for modeling residual stresses induced by orthogonal cutting of AISI316L, Int. J. Mech. Sci., 135 (2018) 53–260.

F. Zemzemi, J. Rech, W. Ben Salem, A. Dogui and P. Kapsa, Identification of a friction model at tool/chip/workpiece interfaces in dry machining of AISI4142 treated steels, J. of Mater. Processing Tech., 209 (2008) 3978–3990.

F. Ducobu and E. Filippi, Material constitutive model and chip separation criterion influence on the modeling of Ti6Al4V machining with experimental validation in strictly orthogonal cutting condition, Int. J. Mech. Sci., 107 (2016) 136–149.

R. Grissa, F. Zemzemi and R. Fathallah, A numericalanalytical approach to predict high cycle fatigue performance of finish machined AISI 316L steel, Int. J. Adv. Manuf. Technol., 94 (2017) 2003–2015.

H. Wu and S. To, Serrated chip formation and their adiabatic analysis by using the constitutive model of titanium alloy in high speed cutting, J. of Alloys and Compounds, 629 (2015) 368–373.

G. R. Johnson and W. H. Cook, A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands (1983) 541–547.

B. Wang and Z. Liu, Shear localization sensitivity analysis for Johnson-Cook constitutive parameters on serrated chips in high speed machining of Ti6Al4V, Simul. Model. Pract. Theory, 55 (2015) 63–76.

A. S. Khan and R. Liang, Behaviors of three bcc metals over a wide range of strain rates and temperatures: Experiments and modeling, Int. J. Plast., 15 (1999) 1089–1109.

M. Calamaz, D. Coupard and F. Girot, A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti-6Al-4V, Int. J. Mach. Tools Manuf., 48 (2008) 275–288.

M. Sima and T. Özel. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti-6Al-4V, Int. J. Mach. Tools Manuf., 50 (2010) 943–960.

J. L. Chaboche and O. Jung, Application of a kinematic hardening viscoplasticity model with thresholds to the residual stress relaxation, Int. J. Plast., 13 (1997) 785–807.

A. Mondelin, Modélisation de l’intégrité des surfaces usinées application au cas du tournage finition de, Thèse de l’Université de Lyon (2012).

T. Mabrouki, F. Girardin, M. Asad and J.-F. Rigal, Numerical and experimental study of dry cutting for an aeronautic aluminium alloy (A2024-T351), Int. J. Mach. Tools Manuf., 48 (2008) 1187–1197.

S. V. Telrandhe, A. K. Saxena and S. Mishra, Effect of microstructure and cutting speed on machining behavior of Ti6Al4V alloy, J. Mech. Sci. and Technol., 31 (5) (2017) 2177–2184.

B. L. Boyce, X. Chen, J. O. Peters, J. W. Hutchinson and R. O. Ritchie, Mechanical relaxation of localized residual stresses associated with foreign object damage, Mater. Sci. Eng., 349 (2003) 48–58.

P. J. Armstrong and C. O. Frederick, A mathematical representation of the multi-axial Bauschingereffect, Technical Report RD/B/N731, CEGB (1966).

J.-L. Chaboche, Sur l’utilisation des variables d’état interne pour la description de la viscoplasticité cyclique avec endommagement, In Problèmes Non Linéaires de Mécanique, Symposium Franco-Polonais de Rhéologie et Mécanique (1977) 137–159.

P. Sanjurjo, C. Rodríguez, I. Peñuelas, T. E. García and F. J. Belzunce, Influence of the target material constitutive model on the numerical simulation of a shot peening process, Surf. Coat. Technol., 258 (2014) 822–831.

N. A. Nasr Mohamed, E.-G. Ng and M. A. Elbestawi, A modified time-efficient FE approach for predicting machining-induced residual stresses, Finite Elem. Anal. Des., 44 (2008) 149–161.

Moussaoui, Influence de l’usinage sur la durée de vie en fatigue de pièces aéronautiques en alliage de titane, Thèse de l’Université de Toulouse (2013).

L. Chen, T. I. El-Wardany and W. C. Harris, Modelling the effects of flank wear land and chip formation on residual stresses, CIRP Ann. -Manuf. Technol., 53 (2004) 95–98.

R. Fathallah, A. Laamouri, H. Sidhom and C. Braham, High cycle fatigue behavior prediction of shot-peened parts, Int. J. Fatigue, 26 (2004) 1053–1067.

D. R. Lesuer, Experiment investigations of material models for Ti-6Al-4V titanium and 2024-T3 Aluminum, Technical Report (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Rihab Grissa is a Ph.D. student of National Engineering School of Sousse, University of Sousse, Sousse, Tunisia.

Rights and permissions

About this article

Cite this article

Grissa, R., Zemzemi, F. & Fathallah, R. Efficient constitutive material model for predicting residual stresses induced by orthogonal cutting. J Mech Sci Technol 32, 2765–2771 (2018). https://doi.org/10.1007/s12206-018-0533-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0533-x