Abstract

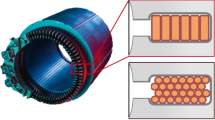

In this paper, a study on the aluminum tube extrusion with a porthole die for deconcentrated welding lines is carried out. The porthole die is consisted of a die mandrel with six inlet ports and two die caps. The aluminum material is extruded into six segments in the die mandrel with six inlets and then inner three of them are welded to compose the inner tube in fist die cap and the others are welded to compose the outer tube in the second die cap. The outer tube has different position of the welding lines to them of the inner tube. In the second die cap, two tubes are welded. The metal flow in the extrusion is analyzed with rigid plastic FEM. The position of welding lines between the inner and the outer tube are predicted. The extrusion experiment is performed and the design of the porthole die is modified to balance the position of the welding line. The extruded profile is tested to evaluate the improvement of the mechanical properties compared to the general porthole extrusion. It is confirmed that the mechanical properties are improved compared to the general porthole extrusion tube.

Similar content being viewed by others

References

A. J. D. Bakker, Weld seams in aluminium alloy extrusions: Microstructure and properties, Ph.D. Thesis, Delft Univ. of Technol. (2016) 108–117.

F. Gagliardi, I. Alfaro, G. Ambrogio, L. Filice and E. Cueto, NEM-FEM comparison on porthole die extrusion of AA-6082, Journal of Mechanical Science and Technology, 27 (2013) 1089–1095.

J. S. Ajiboye and M. B. Adeyemi, The effect of selected parameters on temperature distribution in axisymmetric extrusion process, Journal of Mechanical Science and Technology, 21 (2007) 1553.

S. K. Kim, Seamless thixoextrusion tube manufacturing method and device thereof, Korean Patent. KR100982534B1 (2010).

Wonjin Aluminum Co., Ltd., Development of outrigger for special purpose vehicle using lightweight, high-strength and high productivity aluminum tube. Wonjin Aluminum Research Report (2015) 42–51.

Scientific Forming Technologies Co., DeformTM -3D Ver. 11(2016).

Y. Choi and C. G. Park, Extrusion device for tube having layered structure of different kind of metals and extrusion die used therewith, Korean Patent, KR101559727B1 (2015).

Y. Choi and D. U. Kim, Extrusion device for manufacturing soft metal tube and extrusion die used therewith and extrusion method thereof, Korean Patent, KR101684263B1 (2016).

KATS, Alloys tool steels, Korean Standards, KS D 3753, Korean Agency for Technology and Standards (2013).

KATS, Test pieces for tensile test for metallic materials, Korean Standards, KS B 0801, Korean Agency for Technology and Standards (2007).

ISO, Charpy impact test (V-Notch), ISO 148, International Organization for Standardization, Geneva (1983).

KATS, Metallic materials–bend test, Korean Standards, KS B 0804, Korean Agency for Technology and Standards (2001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Cheol Ko

Min Kuk Choi received his Ph.D. degree from KAIST, Korea, in 2017. He is currently a Senior Researcher at the Agency for Defense Development. His research interests include evaluation of high speed mechanical properties and its application to numerical simulation.

Young Choi received his B.S., M.S. and Ph.D. degrees from Pusan National University, Korea, in 1993, 1995, 1999, respectively. He is currently a Principal Researcher at the Korea Institute of Industrial Technology in Korea. His research interests include simulation of metal forming, high energy rate forming and evaluating of material properties of metal.

Rights and permissions

About this article

Cite this article

Choi, M.K., Park, CG., Choi, Y. et al. Aluminum tube extrusion with the porthole die for deconcentrated welding lines. J Mech Sci Technol 32, 2245–2251 (2018). https://doi.org/10.1007/s12206-018-0435-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0435-y