Abstract

Finishing of a workpiece is a main process in the production. This affects the quality and lifetime. Finishing in order of nanometer, nowadays, is a main demand of the industries. Thus, some new finishing process, such as abrasive flow finishing, is introduced to respond this demand. This may be aided by rotating workpiece and imposing a magnetic field. Numerical simulation of this process can be beneficial to reduce the expense and predict the result in a minimum time. Accordingly, in this study, magnetorheological fluid finishing is numerically simulated. The working medium contains magnetic and abrasive particles, blended in a base fluid. Some hydrodynamic parameters and surface roughness variations are studied. It is found that combination of rotating a workpiece and imposing a magnetic field can improve the surface roughness up to 15 percent.

Similar content being viewed by others

References

R. S. Walia, H. S. Shan and P. Kumar, Abrasive flow machining with additional centrifugal force applied to the media, Machining Science and Technology, 10 (3) (2006) 341–354.

V. K. Jain, Abrasive-based nano-finishing techniques: an overview, Machining Science and Technology, 12 (3) (2008) 257–294.

S. Mamilla Ravi, V. K. Jain and J. Ramkumar, Experimental investigations into rotating workpiece abrasive flow finishing, Wear, 267 (1) (2009) 43–51.

S. M. Ravi, V. K. Jain and J. Ramkumar, Rotational abrasive flow finishing (R-AFF) process and its effects on finished surface topography, International Journal of Machine Tools and Manufacture, 50 (7) (2010) 637–650.

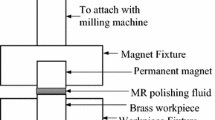

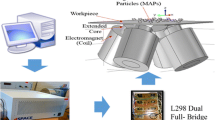

D. Manas, V. K. Jain and P. S. Ghoshdastidar, Nanofinishing of flat workpieces using rotational–magnetorheological abrasive flow finishing (R-MRAFF) process, The International Journal of Advanced Manufacturing Technology, 62 (1-4) (2012) 405–420.

D. Manas, V. K. Jain and P. S. Ghoshdastidar, A 2D CFD simulation of MR polishing medium in magnetic fieldassisted finishing process using electromagnet, The International Journal of Advanced Manufacturing Technology, 76 (1-4) (2015) 173–187.

M. Mikko, V. Taivassalo and S. Kallio, On the mixture model for multiphase flow, VTT Publications (1996).

H. Schlichting, Boundary-layer theory, 6th Ed., Chaps. 14 and 20 (1979).

L. Schiller and Z. Naumann, A drag coefficient correlation, Z Ver Deutsch Ing, 77 (1935) 318–323.

P. R. Chhabra, Non-Newtonian fluids: an introduction, Rheology of Complex Fluids (2010) 3–34.

S. Jha and V. K. Jain, Rheological characterization of magnetorheological polishing fluid for MRAFF, The International Journal of Advanced Manufacturing Technology, 42 (7-8) (2009) 656–668.

S. Jha and V. K. Jain, Design and development of the magnetorheological abrasive flow finishing (MRAFF) process, International Journal of Machine Tools and Manufacture, 44 (10) (2004) 1019–1029.

R. K. Jain, V. K. Jain and P. M. Dixit, Modeling of material removal and surface roughness in abrasive flow machining process, International Journal of Machine Tools Manufacturing, 39 (1999) 1903–1923.

H. J. Sheen, W. J. Chen and J. S. Wu, Flow patterns for an annular flow over an axisymmetric sudden expansion, Journal of Fluid Mechanics, 350 (1997) 177–188.

L. Hanzhuang and T. Maxworthy, An experimental investigation of swirling jets, Journal of Fluid Mechanics, 525 (2005) 115–159.

S. Jha and V. K. Jain, Modeling and simulation of surface roughness in magnetorheological abrasive flow finishing (MRAFF) process, Wear, 261 (7) (2006) 856–866.

S. Genc and P. P. Phulé, Rheological properties of magnetorheological fluids, Smart Materials and Structures, 11 (1) (2002) 140.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Taesung Kim

Saeid Kheradmand received the M.Sc. degree and the Ph.D. degree in Mechanical engineering from Isfahan University of Technology, Isfahan, Iran, in 2002 and 2008, respectively. Since then, he has been with Malek Ashtar University of Technology, Iran, where he is currently an Assistant Professor.

Rights and permissions

About this article

Cite this article

Kheradmand, S., Esmailian, M. & Fatahy, A. Numerical simulation of the combination effect of external magnetic field and rotating workpiece on abrasive flow finishing. J Mech Sci Technol 31, 1835–1841 (2017). https://doi.org/10.1007/s12206-017-0232-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0232-z