Abstract

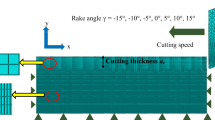

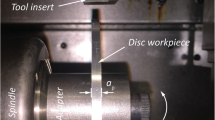

The titanium alloy Ti-6Al-4V has superior properties but poor machinability, yet is widely used in aerospace and biomedical industries. Chip formation and cutting zone area are important factors that have received limited attention. Thus, we propose a high-speed orthogonal cutting model for serrated chip formation. The high speed orthogonal cutting of Ti-6Al-4V was studied with a cutting speed of 10-160 m/min and a feed of 0.07-0.11 mm/r. Using theoretical models and experimental results, parameters such as chip shape, serration level, slip angle, and shear slip distance were investigated. Cutting zone boundaries (tool-chip contact length, length of shear plane, and critical slip plane) and cutting zone area were obtained. The results showed that discontinuous, long-curling, and continuous chips were formed at low, medium, and high speeds, respectively. Serration level, shear slip distance, and slip angle rose with increasing cutting speed. The length of shear plane, tool-chip contact, and critical slip plane varied subtly with increased cutting speed, and rose noticeably with increased feed. Cutting zone area grew weakly with increased cutting speed, levelling off at high cutting speed; however, it rose noticeably with increased feed. This study furthers our understanding of the shear slip phenomenon and the mechanism of serrated chip formation.

Similar content being viewed by others

References

A. H. Li, J. Zhao, Y. H. Zhou, X. X. Chen and D. Wang, Experimental investigation on chip morphologies in highspeed dry milling of titanium alloy Ti-6Al-4V, International J. of Advanced Manufacturing Technology, 62 (9) (2012) 933–942.

M. Sima and T. Özel, Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti-6Al-4V, International J. of Machine Tools and Manufacture, 50 (11) (2010) 943–960.

M. Calamaz, D. Coupard, M. Nouari and F. Girot, Numerical analysis of chip formation and shear localization processes in machining the Ti-6Al-4V titanium alloy, International J. of Advanced Manufacturing Technology, 52 (9) (2011) 887–895.

L. D. Zhu, J. J. Wu, Z. B. Li and C. F. Liu, Investigating chip morphology and its characteristics in the high-speed milling of a Ti-6Al-4V thin plate, J. of Mechanical Science and Technology, 29 (10) (2015) 4359–4366.

X. B. Cui, B. Zhao, F. Jiao and J. X. Zheng, Chip formation and its effects on cutting force, tool temperature, tool stress, and cutting edge wear in high-and ultra-high-speed milling, International J. of Advanced Manufacturing Technology, Doi: 10.1007/s00170-015-7539-7.

H. Schulz, Scientific fundamentals of HSC, Carl Hanser Verlag, Munich (2001) 3–15.

Q. Shi, L. Li, N. He, W. Zhao and X. L. Liu, Experimental study in high speed milling of titanium alloy TC21, International J. of Advanced Manufacturing Technology, 64 (1) (2013) 49–54.

M. B. Mhamdi, S. B. Salem, M. Boujelbene and E. Bayraktar, Experimental study of the chip morphology in turning hardened AISI D2 steel, J. of Mechanical Science and Technology, 27 (11) (2013) 3451–3461.

H. B. Wu and S. J. Zhang, Effects of cutting conditions on the milling process of titanium alloy Ti6Al4V, International J. of Advanced Manufacturing Technology, 77 (9) (2015) 2235–2240.

B. Wang and Z. Q. Liu, Investigations on the chip formation mechanism and shear localization sensitivity of highspeed machining Ti6Al4V, International J. of Advanced Manufacturing Technology, 75 (5) (2014) 1065–1076.

J. Hua and R. Shivpuri, Prediction of chip morphology and segmentation during the machining of titanium alloys, J. of Materials Processing Technology, 150 (2004) 124–133.

R. Komanduri and B. F. Turkovich, New observations on the mechanism of chip formation when machining titanium alloys, Wear, 69 (2) (1982) 179–188.

D. C. Xu, P. F. Feng, W. B. Li, Y. Ma and B. Liu, Research on chip formation parameters of aluminum alloy 6061-T6 based on high-speed orthogonal cutting model, International J. of Advanced Manufacturing Technology, 72 (5) (2014) 955–962.

L. Wan, D. Z. Wang and Y. Y. Gao, The investigation of mechanism of serrated chip formation under different cutting speeds, International J. of Advanced Manufacturing Technology, 82 (2015) 951–959.

B. A. Khidhir and B. Mohamed, Study of cutting speed on surface roughness and chip formation when machining nickel-based alloy, J. of Mechanical Science and Technology, 24 (5) (2010) 1053–1059.

M. Prakash, M. Kanthababu and K. P. Rajurkar, Investigations on the effects of tool wear on chip formation mechanism and chip morphology using acoustic emission signal in the microendmilling of aluminum alloy, International J. of Advanced Manufacturing Technology, 77 (5) (2015) 1499–1511.

M. Cotterell and G. Byrne, Dynamics of chip formation during orthogonal cutting of titanium alloy Ti-6Al-4V, CIRP Annals -Manufacturing Technology, 57 (1) (2008) 93–96.

G. Sutter and G. List, Very high speed cutting of Ti-6Al-4V titanium alloy-change in morphology and mechanism of chip formation, International J. of Machine Tools and Manufacture, 66 (2013) 37–43.

W. S. Lee and C. F. Lin, High-temperature deformation behavior of Ti-6Al-4V alloy evaluated by high strain-rate compression tests, J. of Materials Processing Technology, 75 (1998) 127–136.

P. Guo, Y. Q. Zhao, W. D. Zeng and J. L. Liu, Effect of microstructure on the fatigue crack propagation behavior of TC4-DT titanium alloy, J. of Materials Engineering and Performance, 24 (5) (2015) 1865–1870.

Q. Q. Wang, Z. Q. Liu, B. Wang, Q. H. Song and Y. Wan, Evolutions of grain size and micro-hardness during chip formation and machined surface generation for Ti-6Al-4V in high-speed machining, International J. of Advanced Manufacturing Technology, 82 (2015) 1725–1736.

F. Ducobu, E. Rivière-Lorphèvre and E. Filippi, Experimental contribution to the study of the Ti6Al4V chip formation in orthogonal cutting on a milling machine, International J. of Material Forming, 8 (3) (2015) 455–468.

F. Dal Corso and D. Bigoni, Growth of slip surfaces and line inclusions along shear bands in a softening material, International J. of Fracture, 166 (1) (2010) 225–237.

N. V. Priezjev, Molecular dynamics simulations of oscillatory Couette flows with slip boundary conditions, Microfluidics and Nanofluidics, 14 (1) (2013) 225–233.

G. G. Ye, S. F. Xue, X. H. Tong and L. H. Dai, Slip-line field modeling of orthogonal machining pressure sensitive materials, International J. of Advanced Manufacturing Technology, 58 (9) (2012) 907–914.

A. M. Kovrezhnykh, Determining the shear angle, forces, and sizes of shearing elements during metal cutting, J. of Applied Mechanics and Technical Physics, 50 (1) (2009) 147–154.

S. Zhang, J. F. Li, X. L. Zhu and H. G. Lv, Saw-tooth chip formation and its effect on cutting force fluctuation in turning of Inconel 718, International J. of Precision Engineering and Manufacturing, 14 (6) (2013) 957–963.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Hyung Wook Park

Qingchan Ke received his B.S. in Mechanical Design & Manufacturing and Automation from Beijing Forestry University, China, in 2015. Now he is studying for an M.S. in Mechanical Manufacturing and Automation from Beihang University, China.

Daochun Xu received his Ph.D. in Mechanical Engineering from Tsinghua University, China, in 2010. He is an Associate Professor in Beijing Forestry University, China. His research interesting is high-speed cutting.

Rights and permissions

About this article

Cite this article

Ke, Q., Xu, D. & Xiong, D. Cutting zone area and chip morphology in high-speed cutting of titanium alloy Ti-6Al-4V. J Mech Sci Technol 31, 309–316 (2017). https://doi.org/10.1007/s12206-016-1233-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-1233-z