Abstract

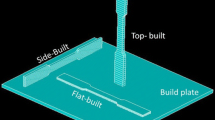

This study aims to define the best building orientation for components produced via the Laminated object manufacturing (LOM) technique to enhance their flexural performance. Results of previous research show that components produced via LOM are capable of with-standing higher deflections than components produced through other layer manufacturing techniques. However, the relation between the building orientation and flexural strength of components has not yet been assessed. Four types of specimens have been manufactured using different building orientations for each type. The specimens have been tested in a machine with four loading points to evaluate their failure mode and identify the best building orientation toward flexural loading. The best building orientation in terms of maximum load before failure is 45°. Furthermore, a repetitive failure pattern is found for each tested condition. Building orientation is confirmed to be a relevant parameter in LOM manufacturing by influencing the mechanical properties of components.

Similar content being viewed by others

References

H. Bikas, P. Stavropoulos and G. Chryssolouris, Additive manufacturing methods and modelling approaches: a critical review, International Journal of Advanced Manufacturing Technology, 83 (1–4) (2016) 389–405.

D. Günther, B. Heymel, J. F. Günther and I. Ederer, Continuous 3D-printing for additive manufacturing, Rapid Prototyping Journal, 20 (4) (2014) 320–327.

Y. Zhang, X. He, S. Du and J. Zhang, Al2O3 ceramics preparation by LOM (Laminated Object Manufacturing), International Journal of Advanced Manufacturing Technology, 17 (7) (2001) 531–534.

G. Marchelli, R. Prabhakar, D. Storti and M. Ganter, The guide to glass 3D printing: developments, methods, diagnostics and results, Rapid Prototyping Journal, 17 (3) (2001) 187–194.

J. J. Beaman, C. Atwood, T. L. Bergman, D. Bourell, S. Hollister and D. Rosen, Additive/subtractive manufacturing research and development in Europe, WTEC Panel Report (2004), http://wtec.org/additive/report/additive-report.pdf.

B. Berman, 3-D printing: The new industrial revolution, Business Horizons, 55 (2) (2012) 155–162.

Y. Chiu, Y. S. Liao and C. C. Ho, Automatic fabrication for bridged laminated object manufacturing (LOM) process, Journal of Materials Processing Technology, 140 (2003) 179–184.

A. Das, G. Madras, N. Dasgupta and A. M. Umarji, Binder removal studies in ceramic tick shapes made by laminated object manufacturing, Journal of the European Ceramic Society, 23 (2003) 1013–1017.

G. Yu, Y. Ding, D. Li and Y. Tang, A low cost cutter-based paper lamination rapid prototyping system, International Journal of Machine Tools and Manufacture, 43 (11) (2003) 1079–1086.

Y. Shuping, F. Liu, J. Zhang and S. Xiong, Study of the key technologies of LOM for functional metal parts, Journal of Materials Processing Technology, 150 (2004) 175–181.

H. Windsheimer, N. Travitzky, A. Hofenauer and P. Greil, Laminated Object Manufacturing of Preceramic-Paper-Derived SiC Composites, Advanced Materials, 19 (24) (2007) 4515–4519.

L. Weisensel, N. Travitzky, H. Sieber and P. Greil, Laminated object manufacturing (LOM) of SiSiC composites, Advanced Engineering Materials, 6 (11) (2004) 899–903.

H. Zhong, X. Yao, Y. Zhu, J. Zhang, D. Jiang, J. Chen, Z. Chen, X. Liu and Z. Huang, Preparation of SiC Ceramics by Laminated Object Manufacturing and Pressureless Sintering, Journal of Ceramic Science and Technology, 6 (2) (2014) 133–140.

C. Gomes, N. Travitzky, P. Greil, W. Acchar, H. Birol, A. P. Novaes de Oliveira and D. Hotza, Laminated object manufacturing of LZSA glass-ceramics, Rapid Prototyping Journal, 17 (6) (2011) 424–428.

D. Klosterman, R. Chartoff, G. Graves, N. Osborne and B. Priore, Interfacial characteristics of composites fabricated by laminated object manufacturing, Composites Part A: Applied Science and Manufacturing, 29 (9) (1998) 1165–1174.

W. Wang, J. G. Conley and H. W. Stoll, Rapid tooling for sand casting using laminated object manufacturing process, Rapid Prototyping Journal, 5 (3) (1999) 134–141.

B. Mueller and D. Kochan, Laminated object manufacturing for rapid tooling and patternmaking in foundry industry, Computers in Industry, 39 (1) (1999) 47–53.

J. Kechagias and V. Iakovakis, A neural network solution for LOM process performance, International Journal of Advanced Manufacturing Technology, 43 (11–12) (2009) 1214–1222.

A. P. King Wah and A. Joneja, Geometric techniques for efficient waste removal in LOM, Journal of Manufacturing Systems, 22 (3) (2003) 248–263.

J. Kechagias, S. Maropoulos and S. Karagiannis, Process build-time estimator algorithm for laminated object manufacturing, Rapid Prototyping Journal, 10 (55) (2004) 297–304.

B. G. Mekonnen, G. Bright and A. Walker, A Study on State of the Art Technology of Laminated Object Manufacturing (LOM), CAD/CAM, Robotics and Factories of the Future, Springer India (207-216) (2016).

J. Park, M. K. Tari and H. T. Hahn, Characterization of the laminated object manufacturing (LOM) process, Rapid Prototyping Journal, 6 (1) (2000) 36–50.

J. Kechagias, S. Maropoulos and S. Karagiannis, Investigation of LOM process quality using design of experiments approach, Rapid Prototyping Journal, 13 (4) (2007) 316–323.

R. I. Campbell, M. Martorelli and H. S. Lee, Surface roughness visualisation for rapid prototyping models, Computer-Aided Design, 34 (10) (2002) 717–725.

J. Kechagias, An experimental investigation of the surface roughness of parts produced by LOM process, Rapid Prototyping Journal, 13 (1) (2007) 17–22.

D. Ahn, J. H. Kweon, J. Choi and S. Lee, Quantification of surface roughness of parts processed by laminated object manufacturing, Journal of Materials Processing Technology, 212 (2012) 339–346.

G. Chryssolouris, J. Kechagias, P. Moustakas and E. Koutras, An experimental investigation of the tensile strength of parts produced by laminated object manufacturing (LOM) process, CIRP Journal of Manufacturing Systems, 32 (5) (2003) 319–322.

K. Paul and V. Voorakarnam, Effect of layer thickness and orientation angle on surface roughness in LOM, Journal of Manufacturing Processes, 3 (2) (2001) 94–101.

Y. S. Liao, H. C. Li and Y. Y. Chiu, Study of laminated object manufacturing with separately applied heating and pressing, International Journal of Advanced Manufacturing Technology, 27 (7–8) (2006) 703–707.

O. S. Es Said, J. Foyos, R. Noorani, M. Mandelson, R. Marloth and B. A. Pregger, Effect of layer orientation on mechanical properties of rapid prototyped samples, Materials and Manufacturing Processes, 15 (1) (2000) 107–122.

Y. S. Liao and Y. Y. Chiu, Adaptive crosshatch approach for the laminated object manufacturing (LOM) process, International Journal of Production Research, 39 (15) (2001) 3479–3490.

C. T. Sun, Comparative evaluation of failure analysis methods for composite laminates, Technical report for the US Department of Transportation No. DOT/FAA/AR-95/109.

D. Olivier, J. A. Travieso-Rodriguez, S. Borrós and G. Reyes-Pozo, Flexural properties and failure mechanism assessment for additive manufactured LOM bars on different building orientations, Society of Plastics Engineers-EUROTEC 2011 Conference Proceedings (2011) 1–5.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Vikas Tomar

Djamila Olivier holds a master’s degree in Materials Engineering. She is currently a Ph.D. candidate and an expert in 3D Printing Materials. Her field of expertise focuses on the Development and Validation of new Polymeric Materials, and the Applications of 3D Printing and Additive Manufacturing Systems.

Ramón Jerez Mesa is an Industrial Engineer and a Ph.D. candidate at the Mechanical Engineering Department of the Polytechnic University of Catalonia. His research activity focuses on Ultrasonic Finishing Processes, the Characterization of Rapid Manufacturing, and 3D Printing via Laminated Object Manufacturing and Fused Deposition Modeling.

Rights and permissions

About this article

Cite this article

Olivier, D., Travieso-Rodriguez, J.A., Borros, S. et al. Influence of building orientation on the flexural strength of laminated object manufacturing specimens. J Mech Sci Technol 31, 133–139 (2017). https://doi.org/10.1007/s12206-016-1212-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-1212-4